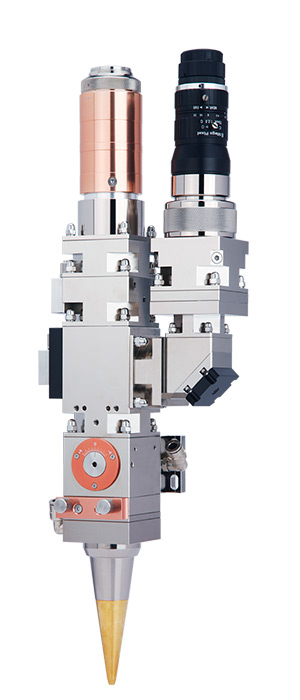

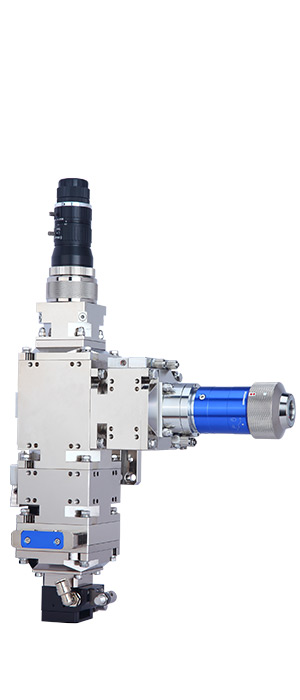

Aluminum alloy welding of WSX high power laser welding head

Aluminum alloys are widely used in various welded structural products due to their light weight, high specific strength, good corrosion resistance, non-magnetic properties, good formability, and good low temperature performance. Aluminum alloy is used to replace steel plate material for welding, and the structural weight can be reduced by more than 50%. At present, it is widely used in aviation, aerospace, automobile, power battery, machinery manufacturing, shipbuilding, chemical industry and daily necessities. However, the welding of aluminum is inseparable from the welding process of the laser welding head.

The welding technology of aluminum alloy laser welding head is a new technology developed in the past ten years. Compared with the traditional welding head welding technology, it has the characteristics of strong function, high reliability, no vacuum condition and high efficiency. It has the advantages of high power density, low total heat input, large melting depth, the same heat input, small heat affected zone, small welding deformation, high speed, easy industrial automation, etc., and has great application advantages. Especially the heat treatment of aluminum alloys. It can improve processing speed, greatly reduce heat input, improve production efficiency and improve welding quality. When welding high-strength and large-thickness aluminum alloys, traditional welding methods cannot fully weld at the same time. However, the keyhole effect can be achieved when a large deep keyhole is formed by deep penetration welding of the laser head.

Laser welding head welding aluminum alloy has the following advantages:

(1) High energy density, low heat input, small thermal deformation, narrow melting zone and heat-affected zone, and large melting depth;

(2) The cooling speed is fast, the welding structure is fine, and the joint performance is good;

(3) Compared with contact welding, laser welding does not use electrodes, thereby reducing man-hours and costs;

(4) The vacuum atmosphere during electron beam welding is not required, and the protective gas and pressure can be selected. The shape of the workpiece to be welded is not affected by electromagnetics and does not generate X-rays;

(5) Weld the metal material on the sealed transparent object;

(6) The laser head can be transmitted over a long distance through the optical fiber, making the process self-adaptive. Through the cooperation with the computer and the robot, the automation and precise control of the welding process are realized.

Comparison of common laser heads for aluminum alloy laser welding

At present, CO2 lasers, YAG lasers and fiber lasers are mainly used. The CO2 laser has high power and is suitable for thick plate welding that requires high power. However, the absorption rate of the CO2 laser beam on the aluminum alloy surface is relatively small, resulting in a large amount of energy loss during the welding process. WSX laser heads usually have relatively low power.

The absorption rate of WSX laser head on the surface of aluminum alloy is relatively higher than that of CO2 laser head. It can be carried out through optical fiber, with strong adaptability and simple process layout. However, wsx output power and photoelectric conversion power are very low. The fiber laser head has the advantages of small size, low operating cost, long service life, good stability and high beam quality. At the same time, the wavelength of light emitted by the fiber laser head is 1070 nm, the absorption rate is higher, the photoelectric conversion rate is 10 times that of the YAG laser head, and the welding head speed is faster than the YAG and CO2 laser heads.

The welding technology of high-power laser welding head equipment is welding head - the general trend of aluminum alloy

As a high energy density welding process, the aluminum alloy laser welding head can effectively prevent the defects caused by the traditional welding process and greatly improve the strength coefficient. Low power laser welding head equipment is difficult to weld thick aluminum alloy plates. At the same time, the absorption rate of the laser head beam on the aluminum alloy surface is very low, and there is a threshold problem when deep penetration welding is to be achieved, so the process is difficult.

The most attractive feature of aluminum alloy laser welding heads is high efficiency. In order to take full advantage of this high efficiency, it must be applied to deep penetration welding with a large thickness. The use of high-power laser heads for deep penetration welding of large thicknesses will be an inevitable trend in future development.