Single module 12kW: heralds the development path of laser cutting core technology

In recent years, 10,000-watt lasers have gradually become the "standard", and fiber lasers are also developing in the direction of higher power, smaller size, and more stable operation. At present, the 10,000-watt lasers on the market are basically multi-mode lasers. Such products are often large in size, have many accessories, and have many hidden troubles. Therefore, improving the output power of a single laser module and optimizing the structure of the whole machine have become the key to further optimizing the performance of the laser. .

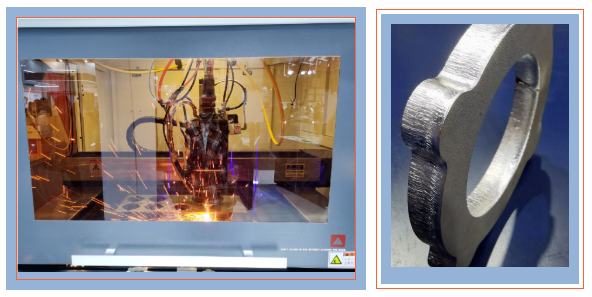

At this optical expo, Raycus released a single-module 12kW laser on-site and performed a light-cutting demonstration on the spot. Judging from the on-site cutting effect, the cutting quality of the single-module 12kW laser is better than that of the multi-mode laser. Compared with the past multi-mode 12kW laser, the volume of the single-mode 12kW laser is reduced by more than 60% and the weight is reduced by more than 40%. In addition, the beam quality is better because it does not need to combine multiple beam paths (75μm core diameter optional @BPP< 2.5mm X mrad), the cutting efficiency of thin plates and medium and heavy plates is also greatly improved.

Single-module 12kW laser emits light on site

According to Raycus Laser, when nitrogen cuts 1-10mm stainless steel, the efficiency of 12kW single-module laser is more than 70% higher than that of multi-mode, and the efficiency of 12-30mm is more than 30% higher than that of multi-mode; when air cutting 1-6mm carbon steel, the single-module laser is more efficient than The multi-mode efficiency is increased by more than 70%, and the 10mm efficiency is increased by 40%. At the same time, the single-module laser simplifies the optical path, circuit, water cooling and other systems between modules, the structure is simpler, the hidden trouble of failure is reduced, and the reliability is greatly improved.

At present, there are many domestic manufacturers that can independently produce 10,000-watt lasers, but only Raycus and Maxphotonics have publicly released 12kW single-module lasers. OFweek Laser Network found that these two domestic laser representative companies have one thing in common, that is, they have complete or relatively complete core device self-research and self-production capabilities, which is the key to achieving higher power and more stable products!

Taking the 12kW single-module laser released by Raycus at this exhibition as an example, all optical components of the laser (including active fiber, 976nm pump source, high-power beam combiner, new-generation R-QP transmission cable, etc.) are autonomous R&D. Among them, the newly upgraded active fiber has a 50% increase in absorption coefficient, a 40% increase in photon darkening performance, and a 40% increase in fiber withstand power compared to traditional fibers. Combined with the new patented nonlinear suppression technology, it can effectively suppress SRS in the fiber. Brightness increased by 30%-40%. The Raycus 976nm pump source has undergone 8,000 hours of real-time testing (about 270,000 hours) in an environment with 33.8 times accelerated aging, and the power remains stable.

100,000-watt laser is about to be delivered: significant for many fields

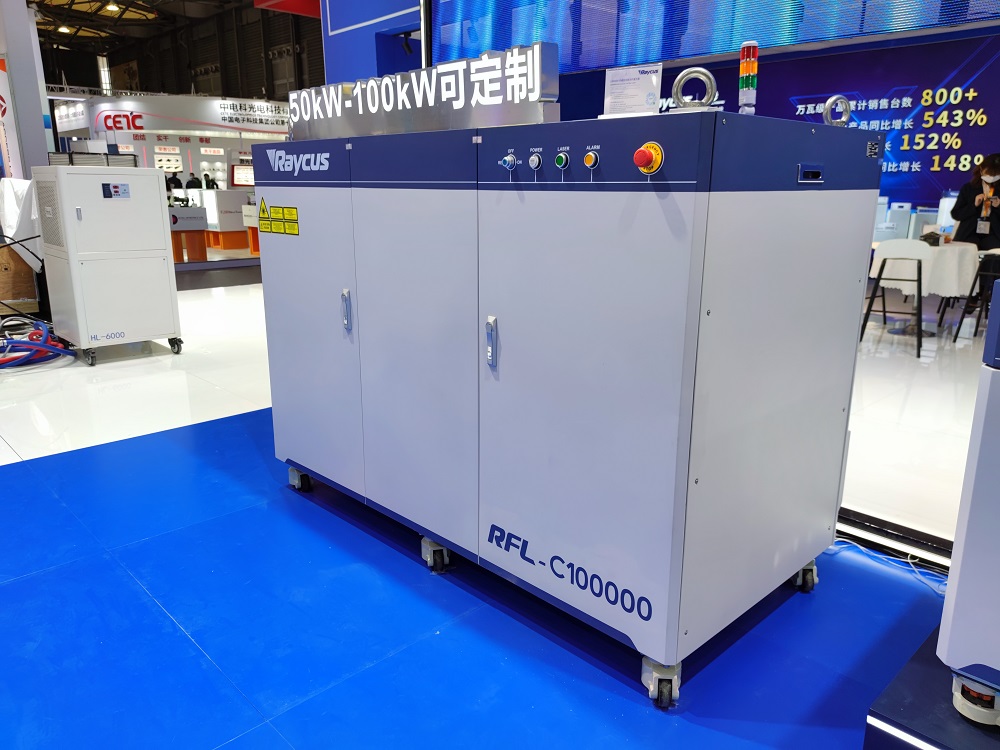

In addition to the live demonstration of the single-module 12kW laser, Raycus also released a more shocking product - a multi-mode 100kW fiber laser. According to OFweek Laser Network, Raycus received an order for a 100,000-watt multi-module ultra-high-power laser from a research institute. Currently, the production work is nearing completion, and the delivery is expected to be completed in the middle of this year. This laser will be used in aerospace, ship high-speed rail, nuclear power and other industrial fields, including high-pressure steam pipeline welding, ship high-speed rail spacecraft and other large workpiece body welding.

100,000 watt multi-module ultra-high power laser

When it comes to 100,000 watts, I have to mention that at the Munich Photonics Exhibition in Germany in 2017, IPG exhibited a 120,000-watt fiber laser, but only sold industrial lasers with a maximum power of 15kW to the Chinese market (at that time, 15kW only Pre-sale, in fact, the highest power on the market is only 12kW). At that time, domestic lasers were in the critical period of tackling 10,000 watts to 10,000 watts. Although some domestic companies were able to achieve 10,000-watt lasers, they had not yet been able to achieve industrialized production and application. After 4 years, the 100,000-watt domestic laser finally broke the foreign monopoly and entered the industrial market.

In the author's opinion, the development of 100,000-watt or higher power lasers is of great significance to the fields of industry, scientific research, and national defense. As far as the industrial market is concerned, the current penetration rate of lasers is less than 10%, and there is a huge space for upgrading and replacing traditional process equipment. In the direction of cold processing, ultrafast lasers undertake the important task of developing applications and expanding the market, while in the direction of thermal processing, ultra-high-power lasers undertake this important task. With the gradual maturity of ultra-high power technology, more high-end application markets will be opened, and the future can be expected!

Laser welding family: breaking the homogeneous competition and opening up a new development situation

In addition to the update of 10,000-watt products, Raycus has also upgraded the welding laser series. In fact, as early as the end of 2018, Raycus has publicly stated that the opportunity in the laser welding market has come, and will vigorously develop welding laser technology. In July 2019, the 10,000-watt shutter prototype developed by the team of Professor Zhu Rihong and Shen Hua of Nanjing University of Science and Technology passed the prototype performance test at Raycus; in October, Raycus and the State Key Laboratory of Advanced Welding and Connection of Harbin Institute of Technology , Harbin Institute of Technology Welding Technology Co., Ltd. signed a tripartite strategic cooperation agreement at Harbin Institute of Technology; in the first half of 2020, Raycus launched "high-power fiber laser with shutter" and "tunable beam high-power fiber laser", entering high-end welding market. Affected by the epidemic in 2020, Raycus laser welding laser sales increased by 152% year-on-year!

It is reported that Raycus has received a good response from the market since it released the ABP laser with adjustable beam last year. In order to meet the needs of more application scenarios, Raycus has enriched the model ratio of ABP lasers. In the past, there was only one model of 6+6. Now it has developed 6+6, 4+4, 4+2, 2+4, 3+3, 2+2 and other models. Models can meet different application needs. All series of ABP lasers use multi-core optical fibers independently developed by Raycus, which can independently adjust the power of the center core and the ring core; a plasma cloud will be formed during the welding process, and there is almost no spatter; the surface of the welding seam is smoother and flatter , and the penetration depth is deeper and the melt pool is wider.

Raycus Laser's full range of ABP lasers

At the same time, in the face of the increasingly prosperous laser handheld welding market, Raycus has launched a small-volume handheld welding laser, which reduces the volume and weight by about 50%, making it easier to integrate. In addition, Raycus also released a welding inspection system jointly developed with Aerospace Sanjiang Laser Industry Technology Research Institute. This welding inspection system can monitor the welding quality in real time before, during and after welding, reduce the inspection cost of enterprises, improve production efficiency, and solve the pain point of high automation enterprises that are difficult to balance between cost, efficiency and quality.

From the layout of welding 3 years ago, to the formation of a multi-model, multi-functional, multi-scenario, laser welding family including detection systems 3 years later, it can be seen that Raycus Laser has strong technical research and development strength and its development in this market. Determination. The annual increase in sales of welding lasers also indicates a broad prospect for this market. At the moment when 10,000 watts of lasers get together in the cutting market and blindly compete for price, only by getting rid of homogeneous competition and opening up new application markets can we truly promote the healthy development of the laser industry.