WSX KC15A laser cutting machine Fiber Laser Cutting Head

Detailed information:

KC15 Fiber Laser Cutting Head

1.This cutting head has a strong advantage in the application of

medium power large format fiber laser cutting.

2.The internal structure of the laser head is completely sealed to

avoid dust contamination on the optical part.

3.This laser head adopts two-point alignment, and the focusing is

adjusted by cam structure accurately and conveniently.

4.The protective window is installed in cartridge, and is convenient

to replace.

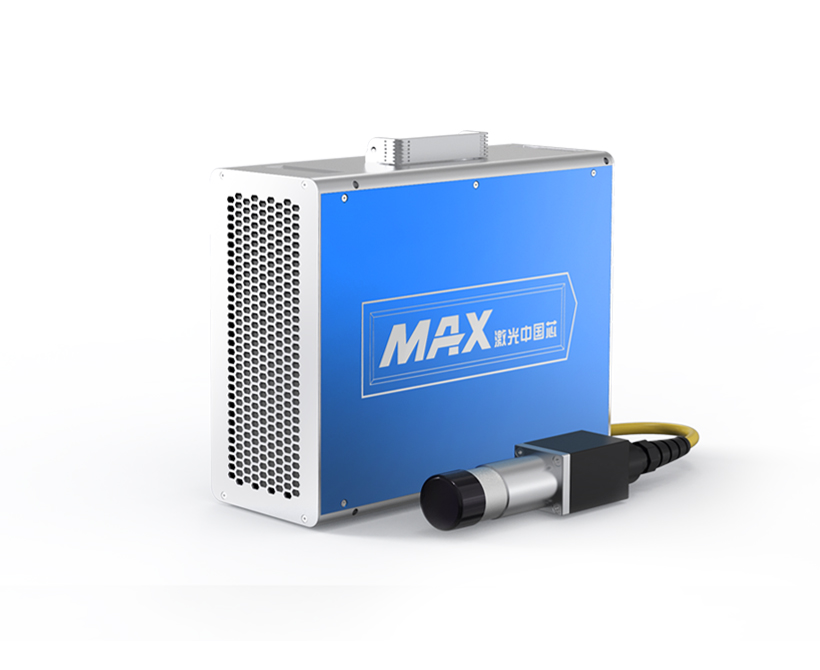

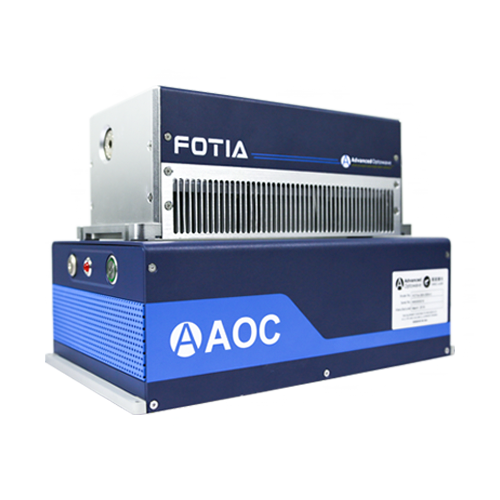

5.Can be equipped with various kinds of laser source with QBH

connector.

QBH components

The core connector for connecting to the laser fiber, providing an industry standard fiber access port.

water cooling components

All water-cooled parts are made of stainless steel, equipped with M5*Ф6 water pipe interface, providing enough cooling water for commuting, cooling the high temperature generated by the heat scattered to the inner wall from the residual light, and cooling the QBH components at the same time.

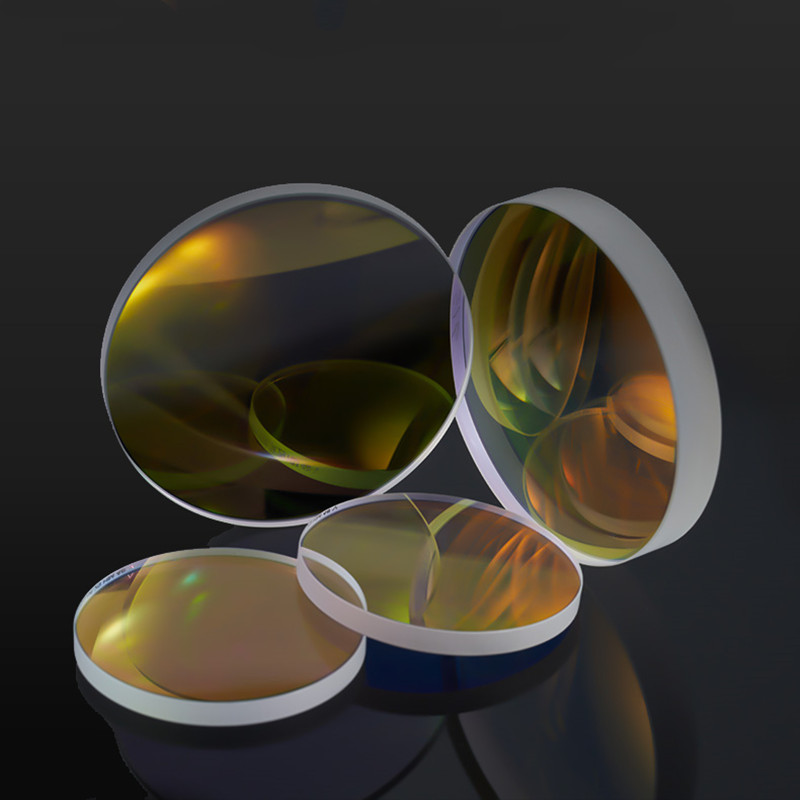

Beam Expander

The beam expander is assembled in the laser head, and includes a beam expander cavity, a beam expander lens group, and a level adjustment system.

Horizontal adjustment device: The beam expander has a built-in light center adjustment position adjustment device. Adjust the two screws in front of the beam expander assembly with an inner hexagon to adjust the light center.

Focus Components

The focusing assembly is assembled in the laser head, including an adjustment structure, a focus locking device, a focusing lens group, a focusing lens cavity and a water cooling system for lens cooling.

The focusing method adopts a cam structure, which is precise and convenient to adjust.

Protective mirror assembly

The protective lens is installed in a drawer, which is easy to replace.

Fix it under the focusing assembly with 4-M4 screws.

The protective mirror is designed to withstand the high pressure of the gas.

sensor assembly

The sensor assembly is located at the end of the laser head and is connected to the body with 4-M4 screws;

The sensor provides capacitive signal for the height adjustment system;

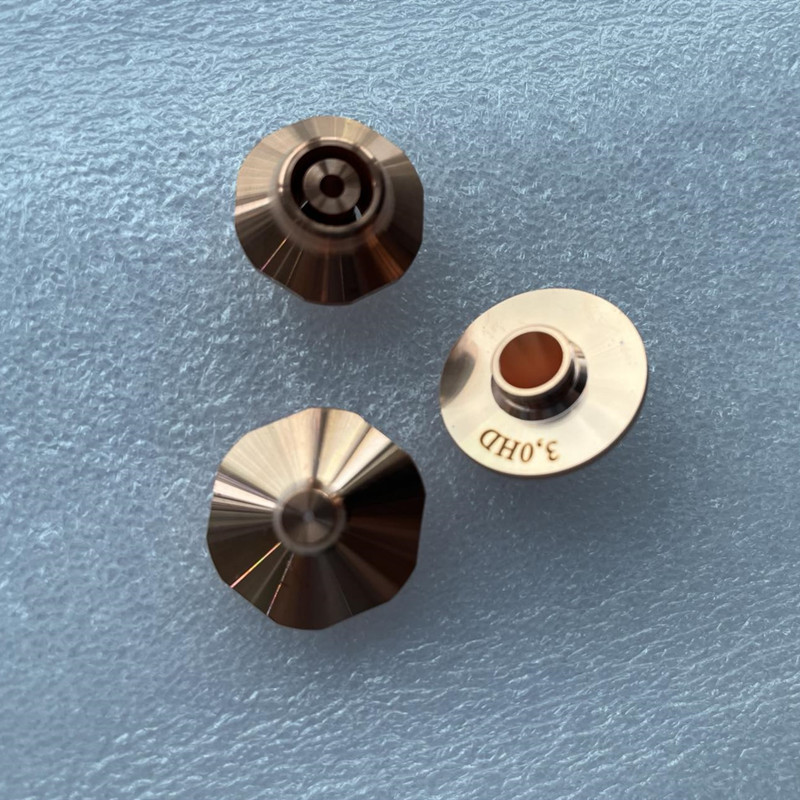

Ceramic Rings and Nozzles

The nozzle and ceramic components are manufactured with high precision, which guarantees the lowest concentricity error during component replacement, thereby reducing or even eliminating adjustment.

In cooperation with the sensor, it provides capacitive signal collection and adjustment for different cutting needs.

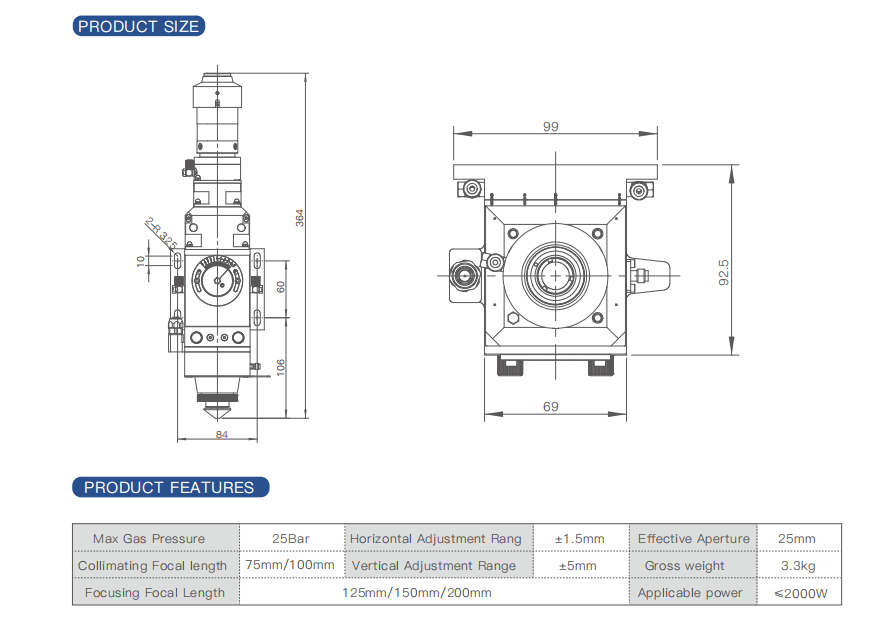

Product parameters:

Maximum power 2000W

Collimated focal length 75mm/100mm

Focusing focal length 125mm/150mm/200mm

Vertical focus range ±5mm

Horizontal adjustment range ±1.5mm

Effective clear aperture 25mm

Maximum air pressure 25Bar

Weight 3.3 kg

Can be used for IPG, SPI, Rofin, nLight, Coherent, Raycus, Maxphotonics and other lasers; QBH connector can be installed