Laser cutting has been widely used in the field of sheet metal cutting in China since it was initially unknown. With the increasing maturity and improvement of laser cutting machine technology in recent years, future laser cutting equipment will be divided into two development paths. One is to upgrade and replace existing technologies, such as when the thickness of the sheet metal is getting thicker, the cost is getting lower; Another way is to study new cutting media and cutting methods. Against the backdrop of increasingly high processing efficiency requirements, how can we improve the efficiency of laser cutting machines?

1. Further improve cutting efficiency and develop efficient and high-precision CNC laser cutting machines to improve cutting speed. Not only should the quality of the beam be improved and the cutting process be changed, but more importantly, the structural optimization design of the machine tool bed and components should be optimized to ensure the stability, reliability, and durability of the machine tool structure, while allowing it to have faster movement speed and acceleration.

2. Develop flexible processing for laser cutting, improve the multi-dimensional freedom of laser cutting machines, and make them more suitable for processing complex curved workpieces. Enhance the promotion and application in two-dimensional and three-dimensional aspects, thereby improving flexible machining.

3. Increase research on laser cutting technology for large and thick plates, master long-distance laser transmission technology, thick plate cutting process, design and manufacturing technology for high-power laser optical path, and develop laser cutting equipment for large and thick plates4. Further enhancing the intelligence of cutting machines, with laser control software as the core, combining fiber lasers with CNC technology, optical technology, and high-precision workpiece positioning through software, combining some functional components of laser cutting machines with other processing methods to develop more convenient and efficient laser processing methods and cutting processes.

So, for the control system of a laser cutting machine, while ensuring stability, reliability, and safety, efficient cutting efficiency and simple and diverse operating methods are even more important. After more than 10 years of rapid development and growth, the control system and software of laser cutting machines have gone through several stages, from foreign high-end CNC systems such as Siemens, Beifu, PA, Fage, to domestic manufacturers such as Baichu, Weihong, Jiaqiang, and Orsendico joining. The method of loading machining files has evolved from simple G code loading to today's intelligent machining. In summary, there are several conventional processing methods:

1. G code import: Directly process by importing manually written or nesting software generated G codes. This is the most traditional and reliable processing method. Most foreign systems use this method.

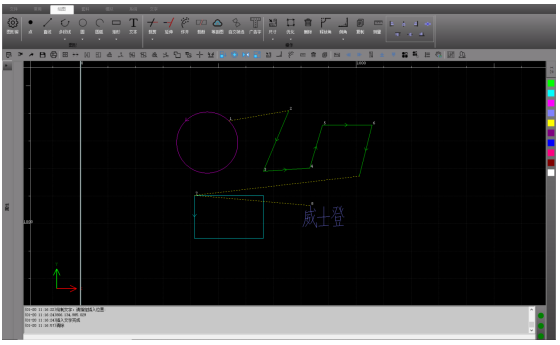

2. Drawing/Part Library Processing: You can manually draw or call the part model of the part library directly on the cutting software, and the cutting software automatically converts the graphics into G code for processing. This is the standard configuration of domestic laser cutting software, simple, convenient, and practical.

3. Graphics import: Laser cutting software can directly load and import CAD drawings such as DXF/DWG, eliminating the need for intermediate operations using nesting software on other machines and improving efficiency.

4. Engineering file import: Laser cutting not only includes G code, but also corresponding processing technology, which is more suitable for batch processing of commonly used products and special processes. Make customer operations easier.

Therefore, based on the German Beckhoff bus CNC system and years of independent research and development, WisCut has launched the BECKHOFF WisCut series of high-end laser cutting software. On the basis of meeting simple and convenient software operation habits, efficient processing methods, and comprehensive processing techniques, taking into account the operating habits and preferences of different customers, several file loading methods are concentrated in WisCut cutting software, Allow customers to choose according to their preferences.

The following is an introduction to the operation mode of WisCut software and the combination of WisNest nesting software.

1 Mode switching

The normal CNC system is divided into multiple operating modes, and WisCut's cutting system can switch between four modes, each of which can perform specific operations. When the mode is selected, it becomes highlighted

2. Processing program selection

The cutting system supports four machining program sources: G-code machining, drawing machining, DXF graphic machining, and engineering file machining

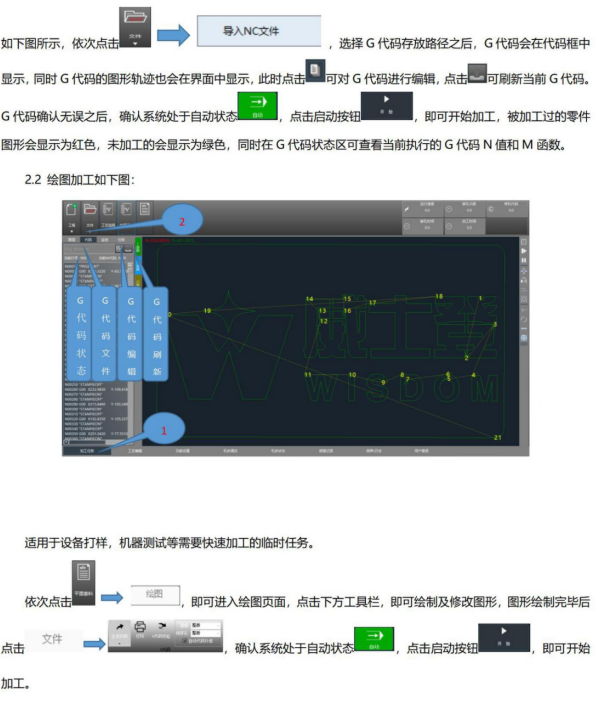

2.1 G code processing

Applicable to customers using nesting software on other computers for graphic layout nesting, generating G code, and then copying the G code to this machine for cutting. In this case, the nesting software needs to generate G code according to the specified format. The specific format requirements and example program are as follows:

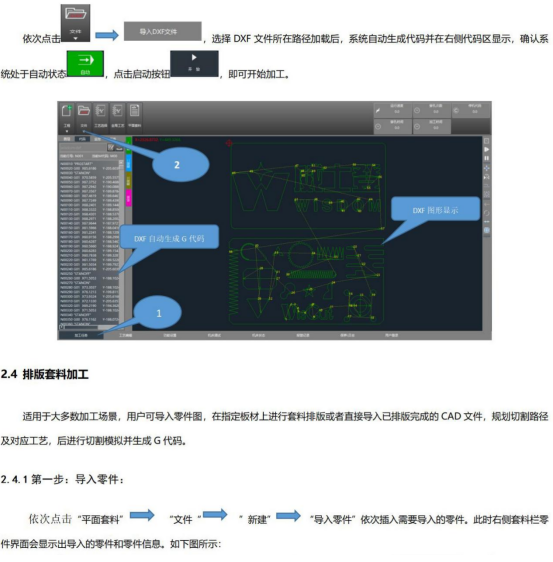

2.3 DXF graphic processing

Applicable to parts that have been edited through CAD or other software to form an independent DXF file. The system can generate G code for processing from this DXF file. It should be noted that this method does not support process modification. If process modification is required, please use layout and nesting to import and process (see 2.4)

2.4.2 Step 2: Nesting treatment

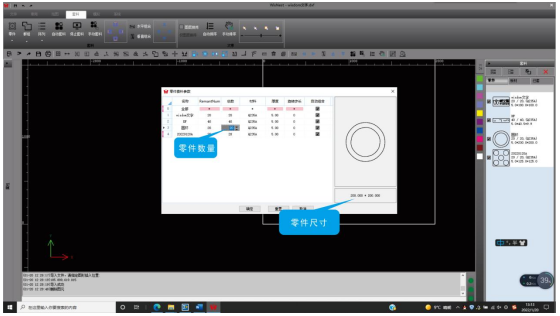

Click on the "Nesting" option in the taskbar above to enter the nesting interface. Right-click in the blank space of the nesting column - parts column on the right, and in the pop-up dialog box, select nesting properties to edit the quantity of parts.

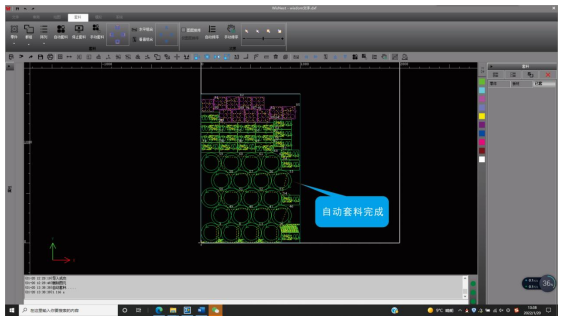

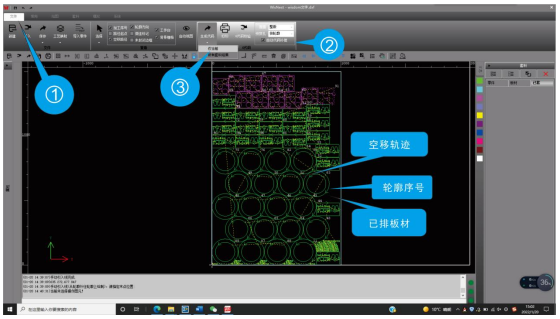

Click on "Automatic nesting" in the upper toolbar to quickly set the sheet size, layout spacing, and preferences for nesting in the pop-up window. After completing the settings, click "OK" and the software will automatically arrange the parts according to the settings. As shown in the following figure:

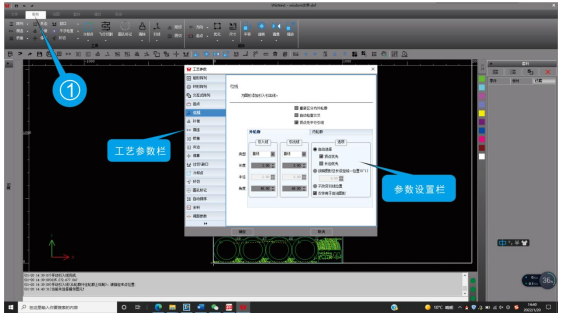

2.4.3 Step 3: Process Settings

Click on the "Common" option in the taskbar above to enter the process settings interface. Select all graphics and start process settings, as shown in the following figure. After completing the settings, click OK.

On this page, different cutting processes such as starting point, direction, lead, flying cutting, common edge, bridging, and cooling points can be set to meet the processing needs of customers.

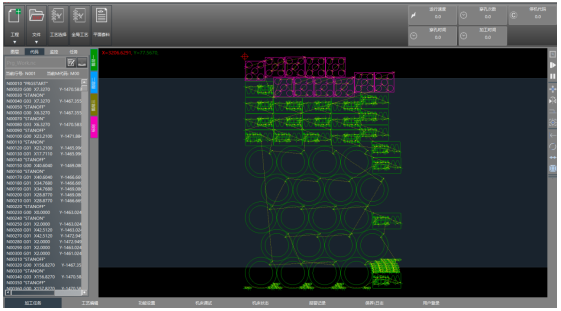

2.4.2 Step 4: Generate Program

Click on the "File" option in the taskbar above to enter the file editing interface. Select the pre perforation and film burning modes on the right side of the toolbar. Select 'By contour' without pre piercing. Then click on "Generate Code" - "Current Only". Automatically generate machining programs to the machining interface. As shown in the following figure:

The above are the import methods of the four processing methods. With the continuous expansion of intelligent application scenarios, the WisCut software continues to be updated, and new processing import methods such as scanning code processing and photography processing will continue to be added in the future.

The application of laser cutting processing is becoming increasingly popular, and the quality, level, and habits of machine operators are also different. At this time, the processing method of a laser cutting software needs to meet different populations, industries, and application scenarios. The four processing file import methods of WisCut high-end laser cutting software have emerged.