DRK32HZG-C 320 Hollow pneumatic chuck front chuck for laser tube pipe cutting machine

-High stability

Integral support base structure to improve support bearing stability

- Strong gripping force

Increased clamping force for heavy pipe processing

-Segmented clamping

Realize a wide range of clamping to meet the requirements of various applications

-Good transmission performance

Precision internal transmission structure, increased lubrication, good wear resistance

1.High precision double chuck design, the front chuck has servo avoidance function to ensure the shortest tailings, improve

material utilization and reduce material cost.

2.It can cut round pipes, oval pipes, square pipes, H-shaped pipes, polygonal pipes and other special-shaped pipes, and can open holes, cut arcs and other processes.

3.High stability machine base. Stress is relieved by high temperature tempering to ensure that the machine avoids deformation and maintains high precision for a long time.

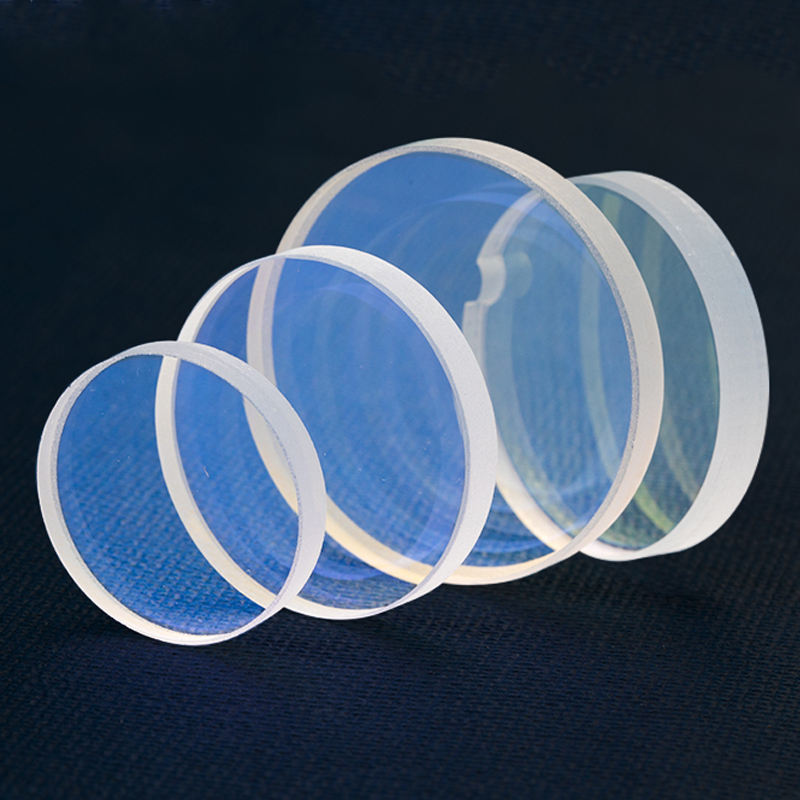

Our laser chuck is mainly designed for laser tube cutting machine. Laser chuck is used for clamping and feeding tubes when cutting tube. It can clamp not only round tubes, but also rectangular tube, L-shap tube, H-shape tube and so on.

It is used base point positioning and it is convenient for the adjustment of the main quipment and greatly shortens the debugging time of the main equipment. And our design is full stroke design. There's no need to adjust the jaw, it is easy to clamp and centering, to achieve switching different pipe diameters, which greatly saving clamping time.

It can realize quick clamping and loosening by rotating air intake from the side, disconnet the air source before working. It is controlled by switching single and double cylinders, which produces differentc clamping forces, which has more advantages of clamping thin-walled tubes and heavy-duty pipes. Becaus of the long length of the parts processed by the cutter, the main chuck used as the head position of laser cutting and feed chuck matched with it are usually installed in pairs on the machine.This penumatic chuck is widely used in special laser pipe cutters and other pipe processing machine system.

Advantages:

a. Full stroke design

b. Wide range of applications, diversification of processing profiles

c. High repetitive positioning accuracy

d. Low maintenance cost, long service life

e. Multiple configurations are available

e. 1 Solid or hollow

e. 2 Comb-type or mortise-groove type claws