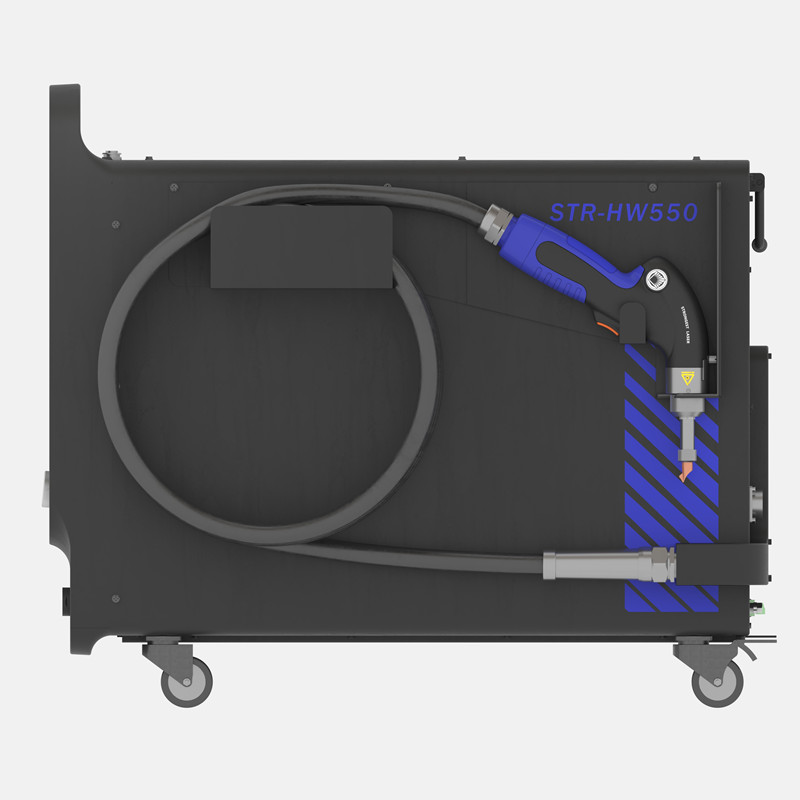

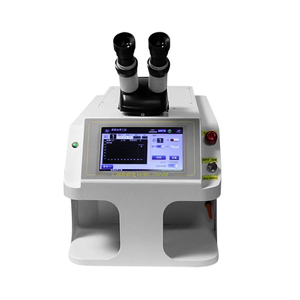

Industrial Air cooling Handheld laser welding machine

STR-HW Series Handheld Laser Welders

Redefine the Performance of Handheld Laser Welders

Larger Penestration

More Stable Operation

Faster Welding Speed

Longer Life Cycle and Up Time

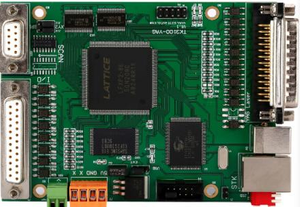

Integrated Design of the Complete Set Ensures Higher Welding Efficiency Longer Service Life, and Lower Maintenance Costs

The whole set of the welded features integrated design, proprietary welding guns and welding wire feeder, built in welding process packages, linked operation and smooth coordination among different components. Meanwile, it is the first product of its kind to incorporate the adaptive welding process package repair function, Bringing higher working efficiency and better welding experience.

Difficiencies That Have Not Been Overcome in Similar Convention Water cooled and Air cooled Laser Handheld Welders

Significant Attention of Welding Effect

The combination of overridden power and power attention will result in lake of connection after 2-3 months of use

High Failure Rate

Some conventional water cooled and air cooled laser handheld welders are suitable to malfunctions due to components with poor interoperability

Composite Parameter Adjustment and Higher Skill Level vRequirements for Operators

When no process package required: a series of parameters such as wire feeding, power, defecating amount

Red shift, and duty cycle need to be adjusted, resulting in replicated operation;Even when a process package is required: the process package is significantly defective and highly professional Requiring users to adjust the detailed parameters by their own, making it difficult for Beginners to understand the Best welding effect

Highly Influenced by External Environmental Factors Such as Temperature and Humidity

The operating temperature of water cooled laser welders falls in the range of 5 ℃ -50 ℃, and that of the air-cooled ones in the range of -10 ℃ -35 ℃, with their performance greatly affected by environmental temperature

Easy to Come Hot and Unable to Work Continuously

When adapting air cooling, traditional welding guns still provide significant limitations in heat distribution and

Requirements intermittently stopping laser emission Conventional welding gun design results in poor heat distribution of materials. Even adapting water cooling

Traditional welding guns are still limited by their tension to become hot and cannot work for long periods of time Traditional Welding Guns Have a Complex Structure, is prone to Malfunctions, and is Heavy in Weight

Conventional welding guns need to be equipped with QBH head/QCS head, water cooled pipe, control cable

Fiber optical cable, etc, Which are suitable to a high failure rate and a large weight of welding guns and cables That result in flexible operation, and susceptibility to fatigue after long term use

STR-HW350

STR-HW450

STR-HW550