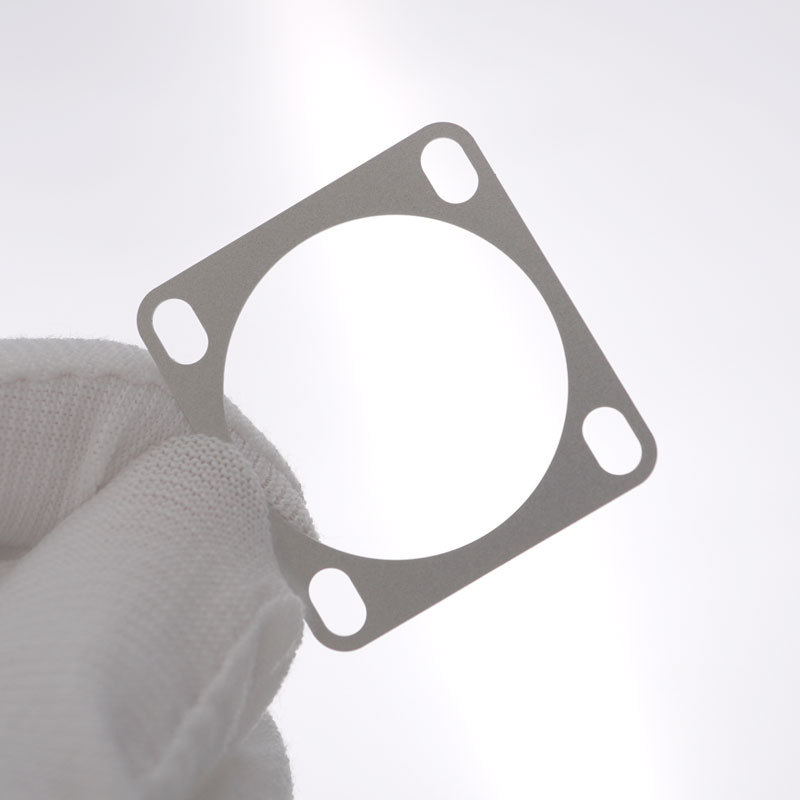

Precise Laser Cutting Process for Cutting 0.020mm Shim Steel Sheet

Introduction

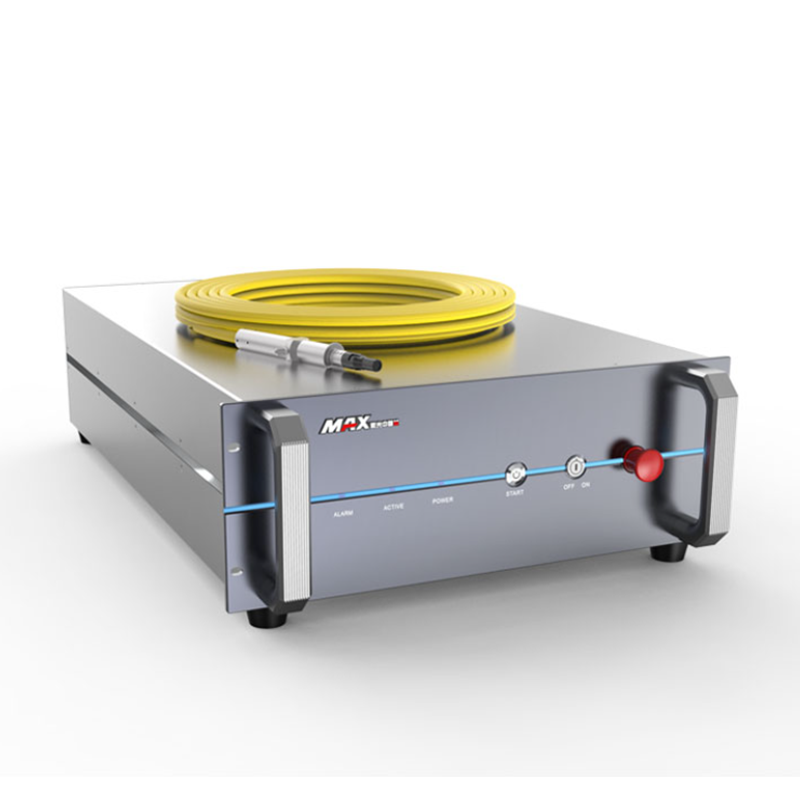

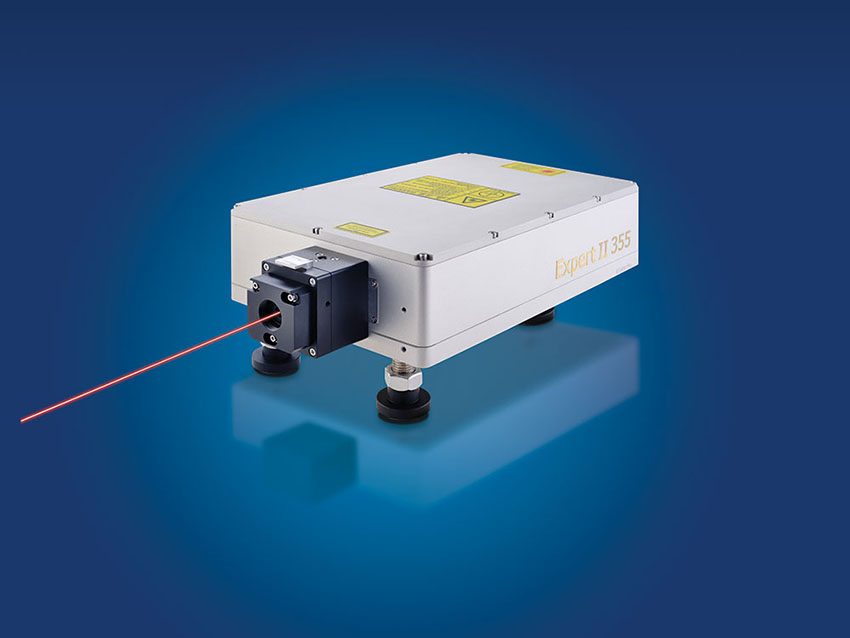

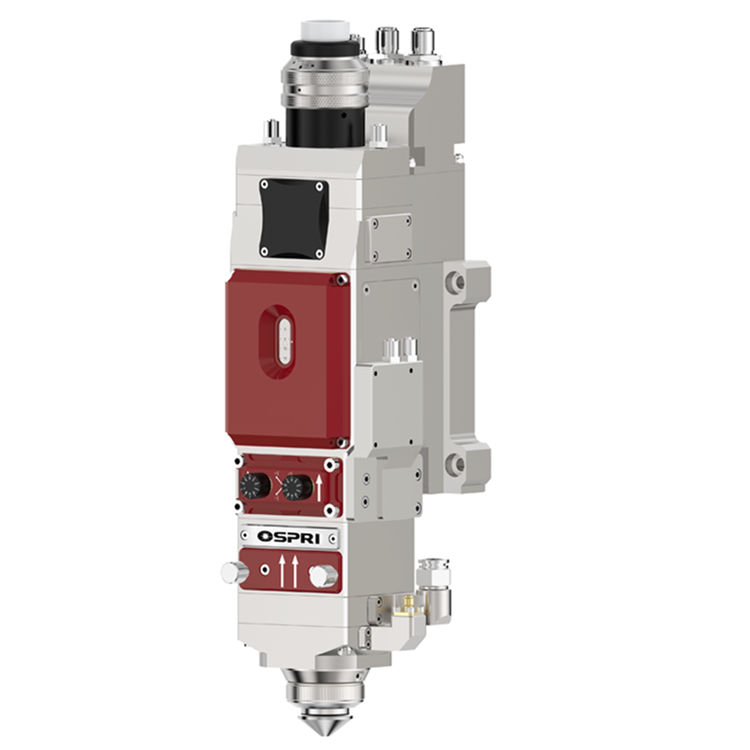

Laser cutting is a highly precise and efficient method for cutting ultra-thin steel sheets, such as 0.020mm shim steel sheets. This process uses a focused laser beam to achieve clean, accurate cuts with minimal thermal impact. It is widely used in industries requiring extreme precision, such as electronics, medical devices, and aerospace engineering.

Functions of Laser Cutting for 0.020mm Shim Steel Sheets

High-Precision Cutting

Capable of achieving micron-level precision with tight tolerances.

Ideal for producing complex, intricate shapes required in precision industries.

Minimal Heat-Affected Zone (HAZ)

The laser’s energy is finely controlled to prevent warping, distortion, or material degradation.

Essential for maintaining the integrity of thin shims.

Burr-Free, Clean Edges

Produces smooth, clean-cut edges without secondary processing.

Reduces the need for manual deburring or post-processing.

Non-Contact Cutting Process

No mechanical force is applied to the material, preventing deformation.

Suitable for delicate, ultra-thin steel sheets.

Ability to Cut Complex Geometries

Can create precise holes, micro-perforations, and intricate patterns.

Useful for customized shim designs in engineering applications.

High-Speed and Efficient Production

Applications of Laser Cutting for 0.020mm Shim Steel Sheets

1. Precision Engineering & Industrial Shims

Used for custom metal shims in mechanical assemblies, reducing vibration and fine-tuning tolerances.

Essential for alignment and spacing applications in high-precision industries.

2. Aerospace Industry

Used in aircraft engine components, sensors, and precision metal layers.

Ensures lightweight, high-strength materials with extreme accuracy.

3. Automotive & EV Manufacturing

Used for precision shims and spacers in engine components, transmissions, and battery systems.

Helps in fine-tuning mechanical tolerances for optimal performance.

4. Electronics & Semiconductor Industry

Used for micro-shielding, conductive layers, and precision metal parts.

Common in thin steel connectors and electronic circuit components.

5. Medical Devices & Surgical Tools

Used for stainless steel medical shims, diagnostic tools, and implantable devices.

Ensures biocompatibility and extreme precision.

6. Energy & Battery Industry

Used for thin metal layers in fuel cells, lithium-ion battery components, and electrical contacts.

Supports energy-efficient designs with high precision.

7. Watchmaking & Luxury Goods

Used for micron-precise components in watches, jewelry, and fine metal engravings.

Ensures decorative yet functional precision designs.

Advantages of Laser Cutting for 0.020mm Steel Shims

✔ Extreme Precision – Achieves micron-level accuracy.

✔ Minimal Heat Effect – Prevents material distortion and maintains integrity.

✔ Burr-Free Cutting – Clean, smooth edges without additional finishing.

✔ Non-Contact Processing – No risk of mechanical damage or deformation.

✔ Supports Complex Designs – Ideal for intricate, customized shim patterns.

✔ Fast & Efficient – Suitable for mass production with consistent quality.