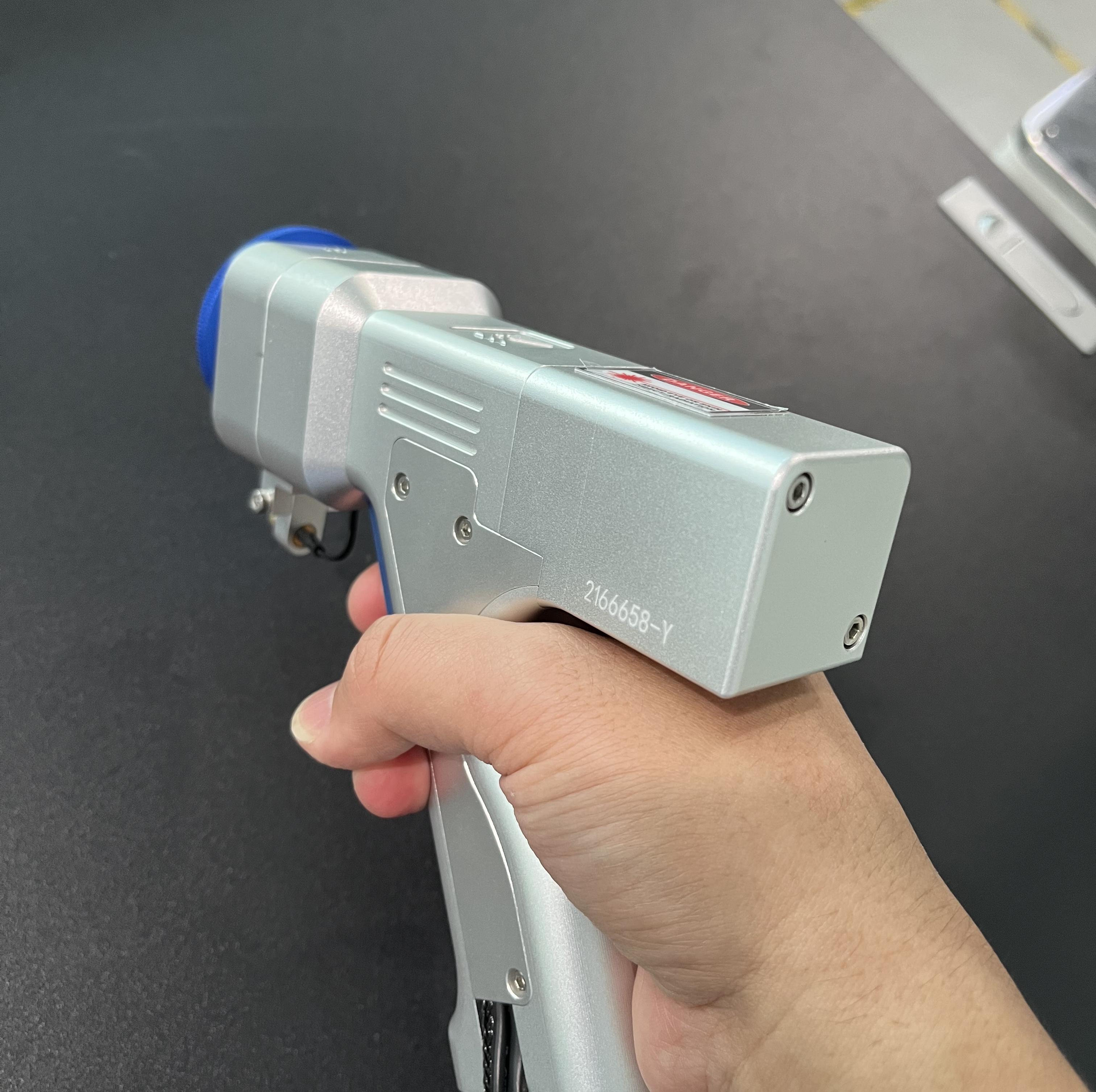

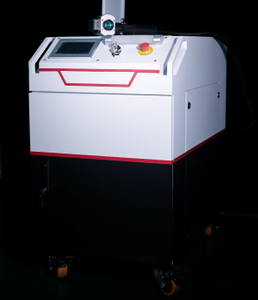

Laser Rust Removal Machine Laser Machinery hand held fiber laser welding machine 2000w

Applications:

The backpack laser rust removal is widely used for the surface laser degreasing, laser paint removal, laser removal of zinc, laser film removal, laser cleaning, such as coating, etc

Rust removal:

High energy pulsed laser focusing on the surface of object to simulate plasma, continuous irradiation of high-energy plasma instantaneous formation and expansion, resulting in a series of tiny explosions, format plasma blasting, finally achieve the relative smooth corrosive layer of object surface to

physical blasting burst, and move through the high speed laser spot to form a plume that will clean the debris to complete the cleaning. Mainly used in metal rust.

Paint removal:

For the paint and the surface of the chemical coating and special process, based on the surface and the base material has different absorption and damage threshold on laser, laser destruct the surface coating after focusing, after air contact, there are a series of complex photochemical reactions, oxidation, The final reaction product is in the form of gas discharge, the special mode of the laser below the master batch damage threshold, can peel off the coating, do not hurt the base material. Mainly used for paint removal and coating stripping.

product description:

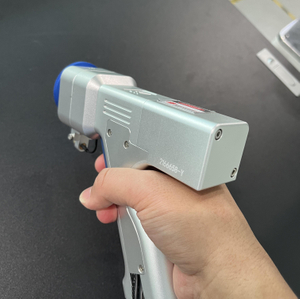

"KRD Handheld Fiber Optic Continuous Cleaning Head Control System" consists of controller and touch screen (including

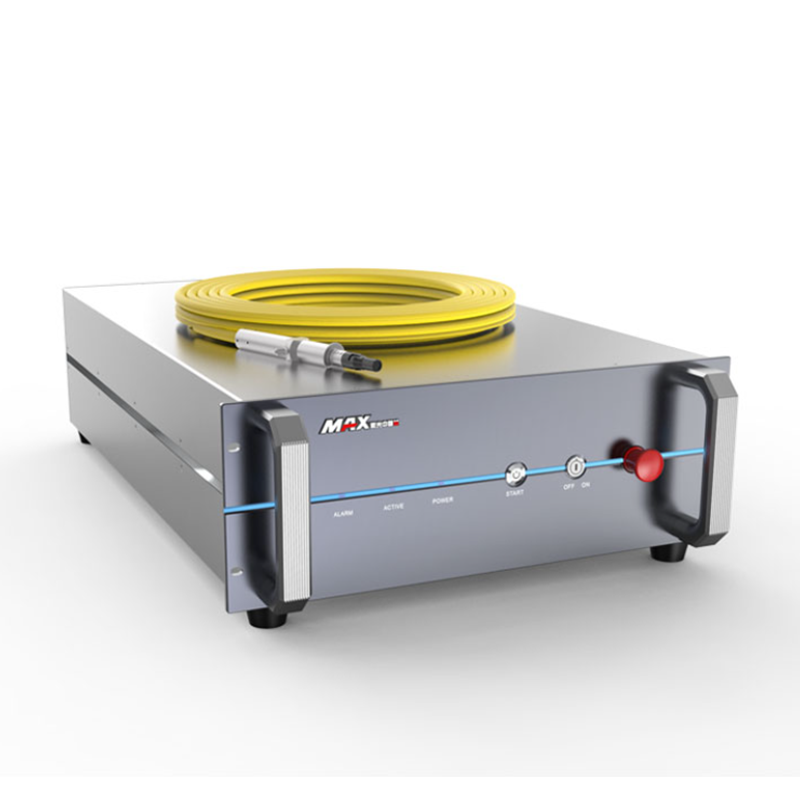

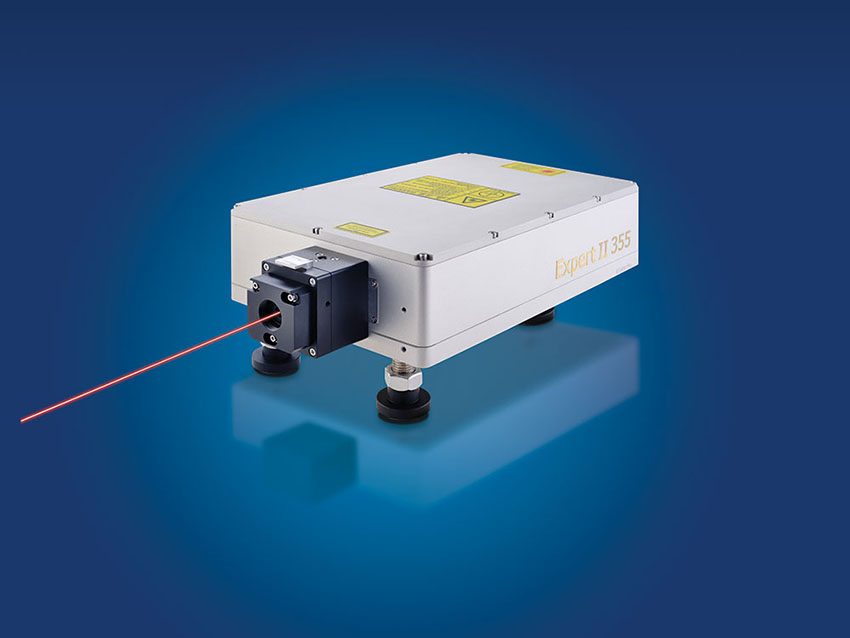

connecting lines). This product is suitable for fiber laser 1000-3000W, swing head (single

galvanometer swing) control;

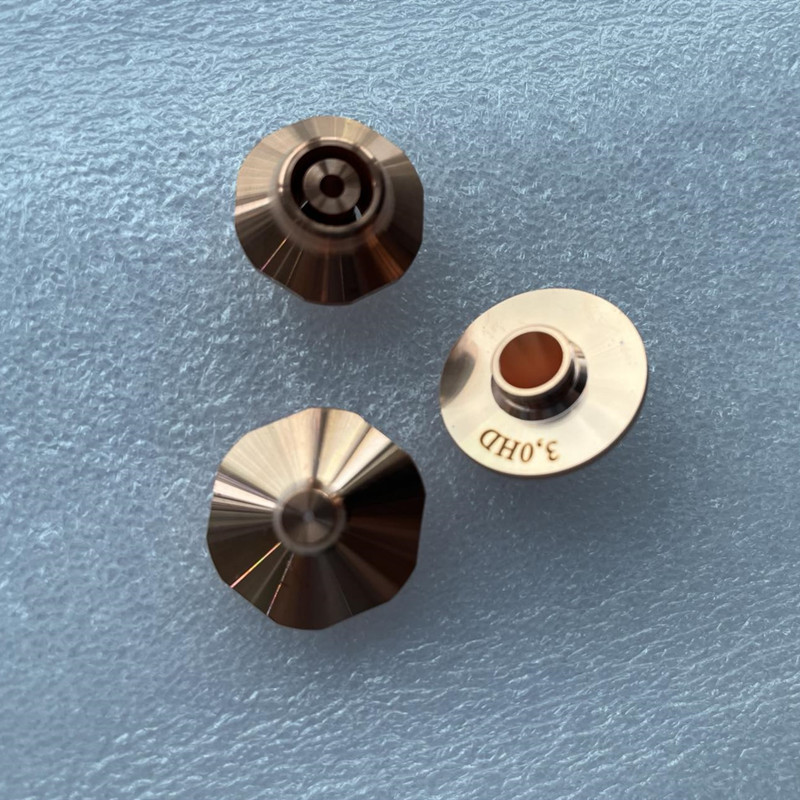

Accessories: 1 handheld cleaning gun, 1 controller, 1 touch screen, 1 cable. A number of accessories (including 1 ±15V switching power supply and 5 protective lenses).

Controller Installation and Port Definition

◎ ◎ The back of the controller is fixed by screws on the bottom skirt.

Laser and software wiring diagram As shown in the figure, the red font line mark

(Raycus, JPT, Maxphotonics, Tottenham, GGW, Keplin, Feibo, , ) and so on.

Laser connection precautions: some lasers need to be short-circuited when they emit light in the external control state

To interlock and supply power to one of the external control lines, please read the laser wiring instructions carefully.

Single vibration hand head wiring diagram (conventional wire feeder)

Precautions for hand-held cleaning head: : (controller red dial: 1, 2, 3 up, 4 down).

Handheld aerial plug wiring diagram

Precautions for the power supply of the control card: : The positive and negative 15V switching power supply and the power supply for the control system

The 24V switching power supply for laser enable, air valve, etc. needs a total of 0V, so the installation and wiring

When it is necessary to short-circuit the 0V of the two switching power supplies, or connect the 0V of the 24V switching power supply to

Connect to the GND of the output port.

1 X-KO1 anti-interference isolator: It is an optional electronic device on the handheld laser equipment.

The preparation work site environment is better, and there is no strong interference equipment around, so it is not necessary to install. Isolator

After installation, it can isolate the impact of some external strong interference sources on the equipment control circuit (such as: argon arc

welding, etc.). Please purchase this device by yourself or consult the relevant suppliers.

System connection and debugging

Follow the steps above to connect the laser and other components, then connect the touch screen to the controller

The cable is connected. Repeatedly check whether each circuit of the equipment is connected correctly against the circuit diagram, and confirm

Power on after everything is normal.

Touch screen and controller connection diagram

The operation and setting of the X-Z03 system are all done on the touch screen. The interface is simple and clear,

Including: welcome interface, home page, craft, settings, status.