Precision Laser Cutting: Precision laser cutting is a technology used to cut stainless steel parts with an extremely high level of accuracy. It can achieve tolerances as fine as 0.012mm, making it ideal for applications that require exact precision, such as medical, automotive, and electronics industries.

Stainless Steel Processing: Stainless steel is a popular material due to its corrosion resistance, strength, and durability. Laser cutting machines are perfectly suited for cutting thin stainless steel sheets (as thin as 0.012mm), ensuring clean, smooth, and precise cuts without any material distortion.

0.012mm Thickness: Laser cutting machines can effectively process very thin stainless steel sheets, down to a thickness of 0.012mm, without compromising the material’s integrity. This is especially important for applications that require delicate or small parts with minimal heat impact.

High Precision Cutting: With precision laser cutting, it is possible to achieve fine, smooth cuts with minimal burrs. The laser cutting process ensures exact edges and dimensions, ideal for components used in high-precision industries such as aerospace, medical devices, and electronics.

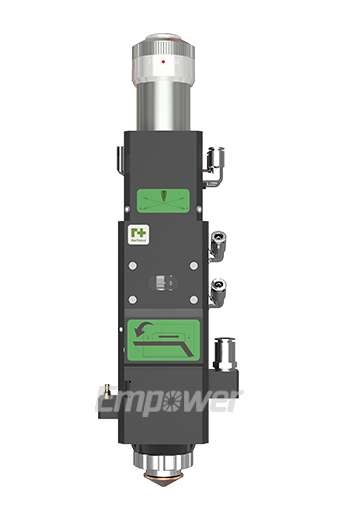

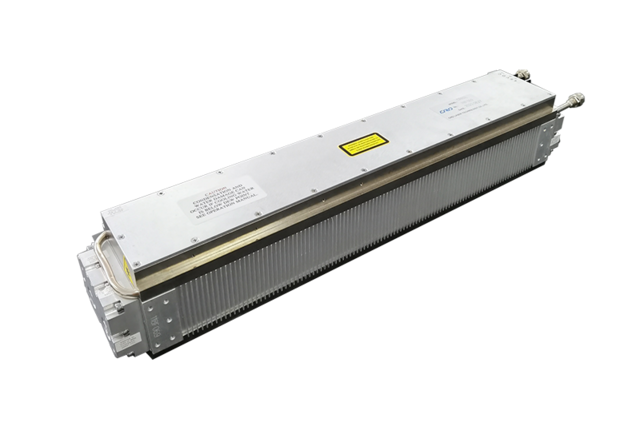

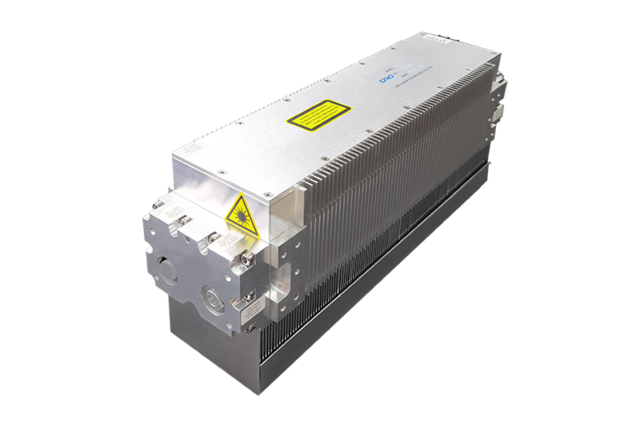

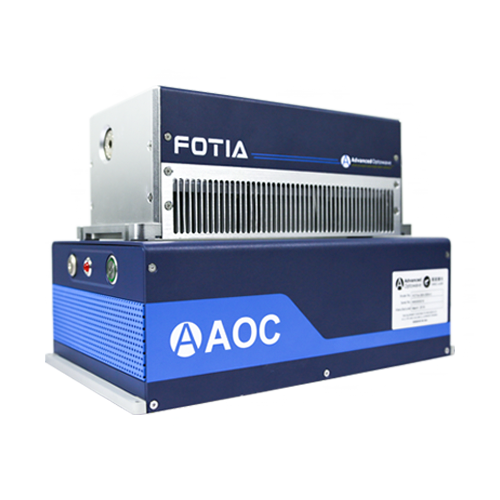

Laser Beam Focus: Laser cutting machines focus the laser beam to a very fine point, allowing for the accurate cutting of fine details. This focused beam is key to maintaining the integrity of materials like stainless steel, ensuring precise cuts in intricate designs.

Thin Sheet Metal Cutting: Laser cutting is particularly effective for thin sheet metal, such as 0.012mm thick stainless steel. The focused laser beam cuts through the material cleanly and efficiently, offering high-speed processing with minimal thermal distortion.

Laser Cutter for Stainless Steel: Laser cutting machines are designed specifically for stainless steel processing. These machines provide high cutting speeds and precision, and are commonly used in industries that require stainless steel components, such as automotive manufacturing, electronics, and construction.

CNC Control: Computer Numerical Control (CNC) systems control the laser cutting machines, allowing for automated, highly accurate, and repeatable cutting processes. CNC control ensures that every part cut is identical and meets the exact specifications required for each job.

Fine Detail Cutting: Precision laser cutting machines can cut complex patterns and fine details in stainless steel with a tolerance as small as 0.012mm. This capability is essential for manufacturing small parts, intricate designs, or parts with small holes and thin walls.

Heat Affected Zone (HAZ): One of the key considerations in laser cutting is managing the heat affected zone, which can cause changes in material properties if not carefully controlled. Precision laser cutting minimizes the size of the HAZ, ensuring that the stainless steel remains unaffected by thermal damage and preserving the material's strength.

Precision Mechanical Components: Laser cutting is used for manufacturing precise mechanical parts such as gears, brackets, and connectors, which are commonly required in industries like automotive and aerospace.

Medical Devices: Stainless steel parts with high precision are essential for medical equipment like surgical instruments, implants, and diagnostic devices, making laser cutting a crucial technology.

Electronics: Laser cutting is widely used for creating small and precise components for electronics, such as connectors, frames, and housings for devices like smartphones and computers.

Automotive Industry: Laser cutting of thin stainless steel is employed to create body panels, structural components, and intricate parts for automotive manufacturing, ensuring high accuracy and quality in the final product.