High-Precision Laser Cutting Solution for 0.060mm Stainless Steel Thin Sheets

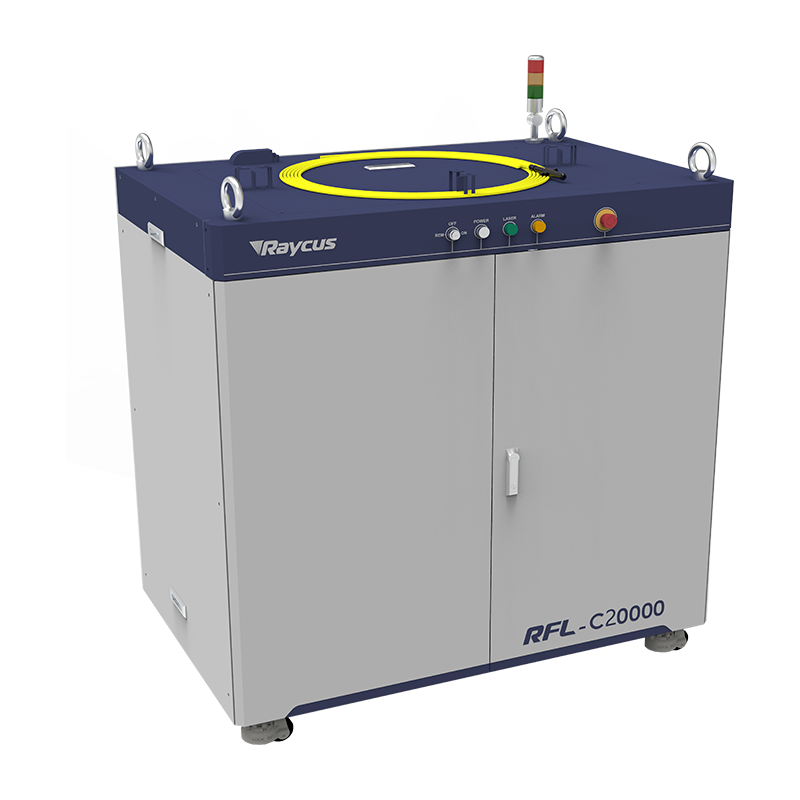

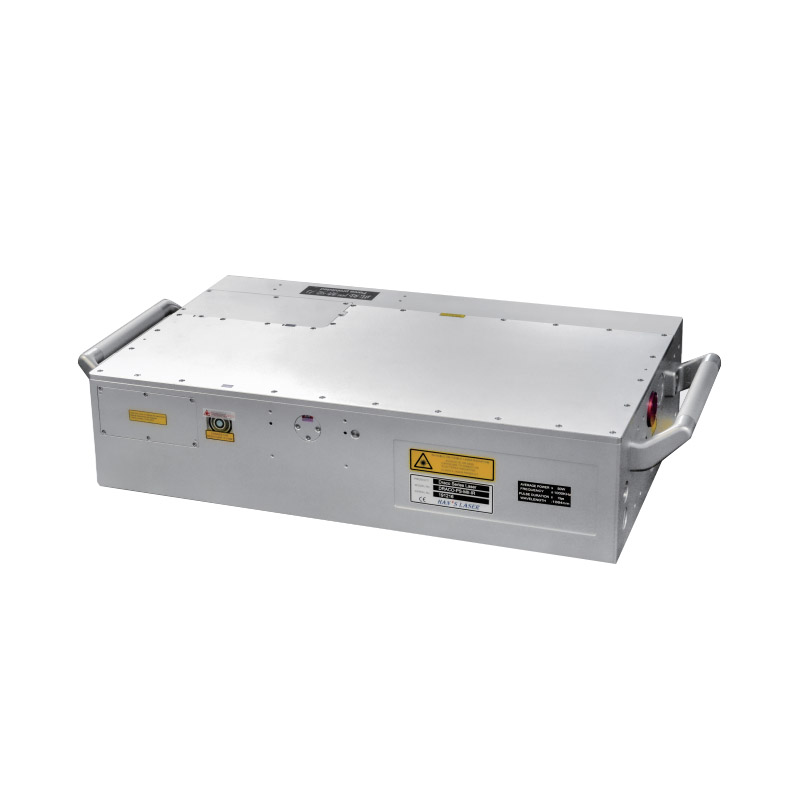

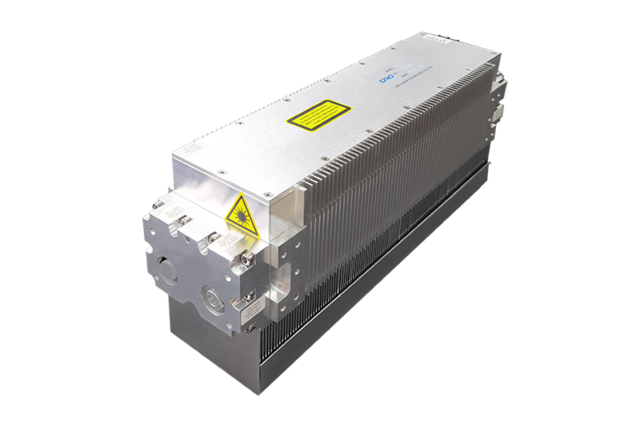

This precision laser cutting system is engineered specifically for ultra-thin metal sheet processing, especially 0.060mm stainless steel. With its high-speed fiber laser source, micron-level motion control, and CCD visual alignment system, the machine delivers clean, accurate, and burr-free results for micro-feature components.

Typical Applications for 0.060mm Stainless Steel Sheets

SMT stencils and solder paste masks

Micro-perforated metal filters and screens

Electronic and communication components

Medical precision parts and sensor housings

Microfluidic channels and aerospace foil parts

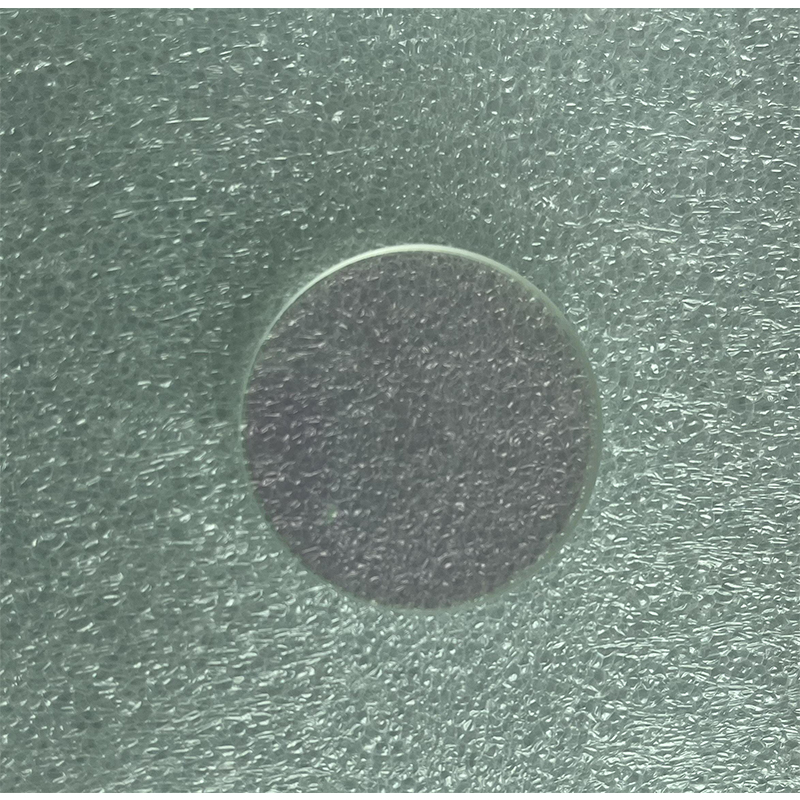

The machine provides stable repeatability (±2μm), auto hole correction, and non-contact cutting, ensuring that even delicate 0.060mm stainless steel sheets are processed with minimal thermal distortion or mechanical stress.

Machine Technical Parameters Table

| Parameter | Specification |

| Model | SC-G6060 |

| Laser Type | Fiber Laser (IPG) 100W–200W |

| Wavelength | 1070 nm |

| Beam Quality | M² < 1.1 |

| Cutting Thickness Range | 0.03 mm – 1.0 mm |

| Optimal Processing Thickness | 0.050mm–0.060mm (Stainless Steel) |

| Cutting Accuracy | ±5 μm |

| Repeatability | ±2 μm |

| Cutting Line Width | 0.02 – 0.03 mm |

| Positioning Accuracy | ±2 μm |

| CCD Positioning Accuracy | 0.01 mm |

| Cutting Speed | Up to 22,000 holes/hour |

| Working Area | 650 mm × 650 mm |

| Max Clamping Size | 680 mm × 720 mm |

| Motion Platform | Natural Granite Base |

| Z-Axis Accuracy | < 0.01 mm |

| Main Drive Components | Panasonic, Copley, Renishaw |

| Controller | Radium Tech + HKStudio software |

| Supported File Formats | LMC, LMD, CNC, DXF, STC, TCM |

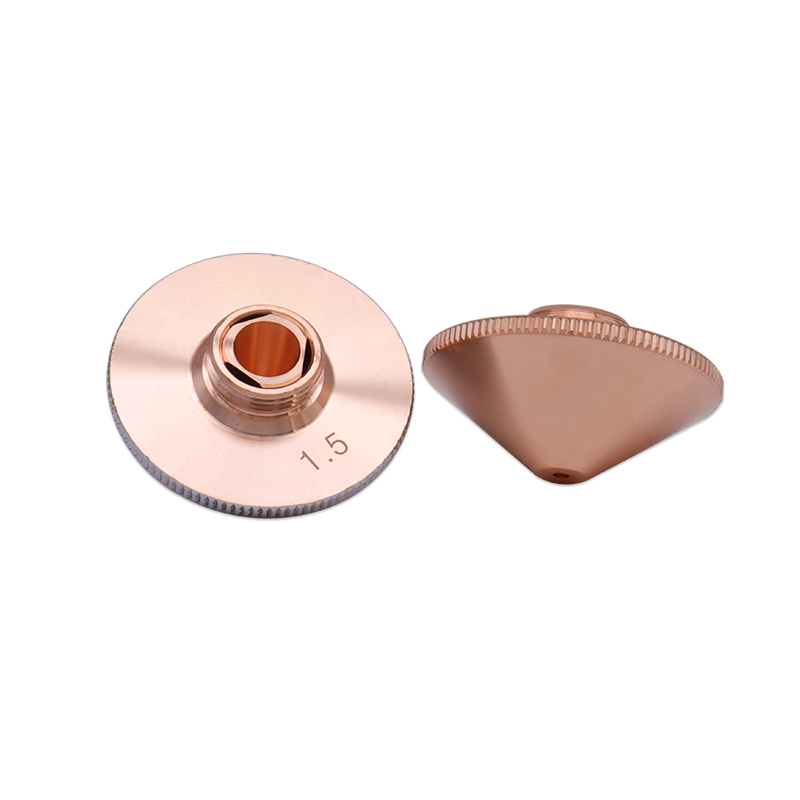

| Auxiliary Gases | Industrial Oxygen (8–10 Kg), Air (16 Kg) |

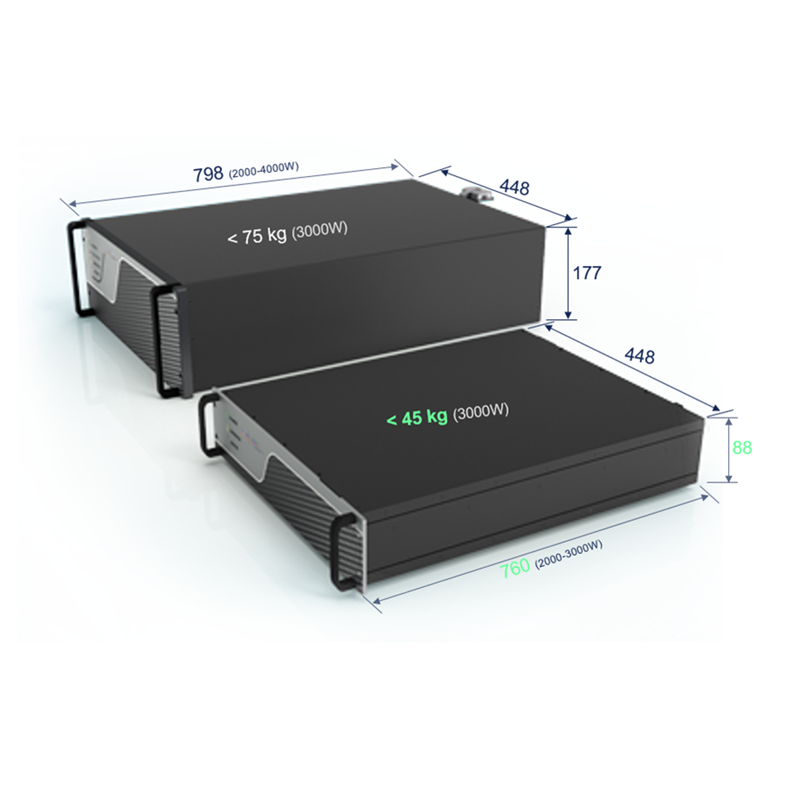

| Power Supply | 220V, 3KW |

| Overall Dimensions | 1640mm × 1380mm × 1500mm |

| Equipment Weight | Approx. 2200 Kg |

✅ Why Choose This Machine for 0.060mm Stainless Steel?

Superior Flatness & Stability thanks to granite base and closed-loop control

Fast Prototyping & Batch Production with high throughput

No Material Deformation with non-contact precision laser cutting

Ideal for Complex Geometries in electronics, medical, and aerospace industries

Auto Hole Patch + CCD ensures micron-level alignment and accuracy