Precision Stainless Steel Laser Cutting Machine

For SMT Stencil & Micro-hole Processing

Application Overview

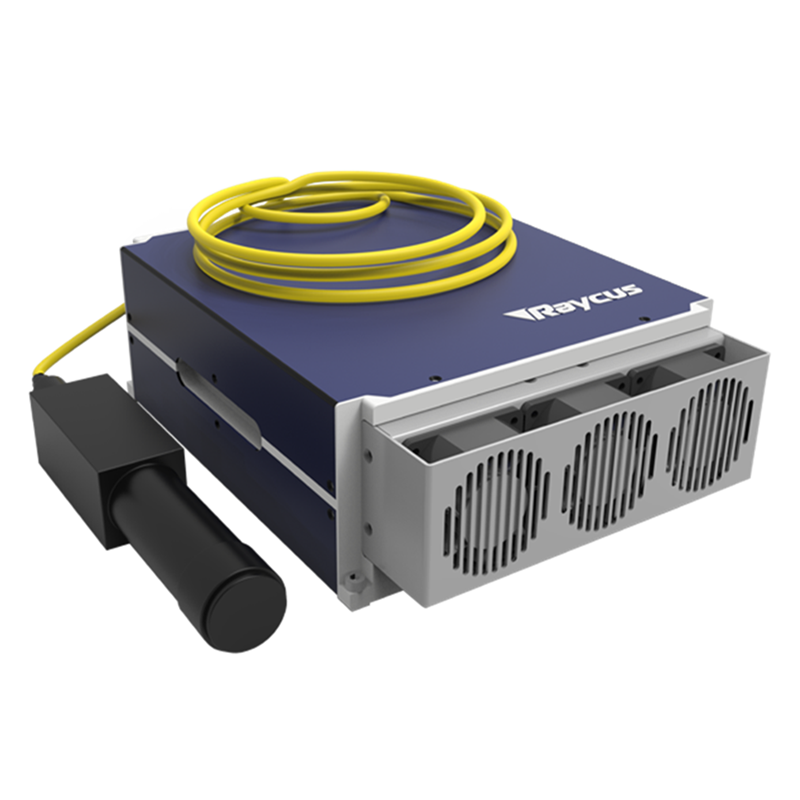

This high-precision laser cutting system is engineered for advanced stainless steel sheet processing, focusing on ultra-fine micro-hole fabrication and SMT stencil production. Equipped with CCD visual alignment, granite base construction, and a fiber laser system, it delivers micron-level accuracy and high production efficiency.

Main Applications:

SMT stencil cutting

Micro-hole drilling in precision components

High-precision pattern cutting

Manual carrier loading with CCD-assisted positioning

Suitable for electronics, medical devices, aerospace & instrumentation sectors

Technical Specifications

| Item | Specification |

| Model | SC-G6060 |

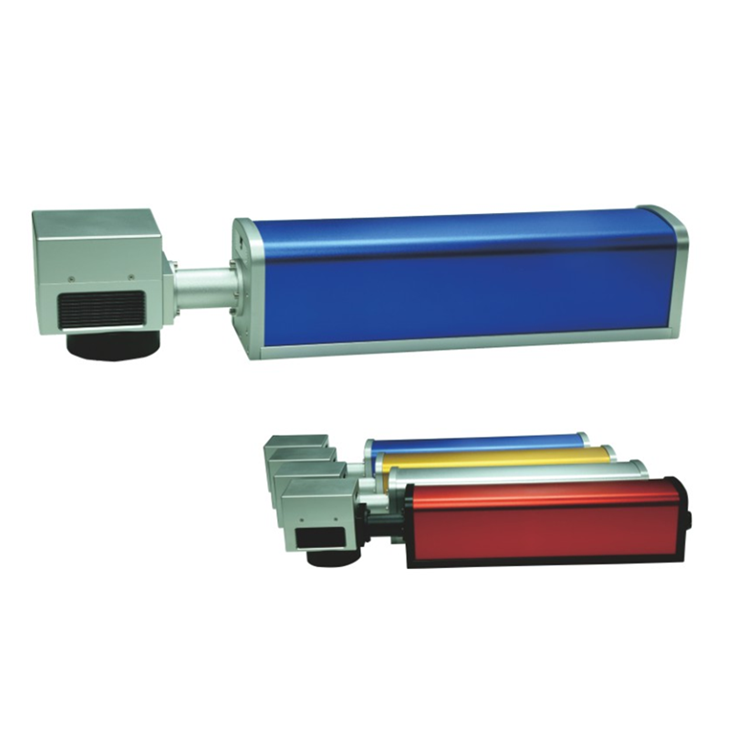

| Laser Brand | IPG (100W–200W, 1070nm) |

| Laser Beam Quality (M²) | < 1.1 |

| Cutting Accuracy | ±5μm |

| Repeat Positioning Accuracy | ±2μm |

| Cutting Line Width | 0.02–0.03mm |

| Effective Cutting Area | 650mm × 650mm |

| Max Clamping Size | 680mm × 720mm |

| Cutting Thickness | 0.03mm – 1.0mm |

| Max UPH (holes/hour) | 8,000 – 22,000 |

| Positioning System | CCD visual positioning (Accuracy: 0.01mm) |

| Z-axis Control Accuracy | < 0.01mm |

| Yield Target (within 7 days) | ≥90% |

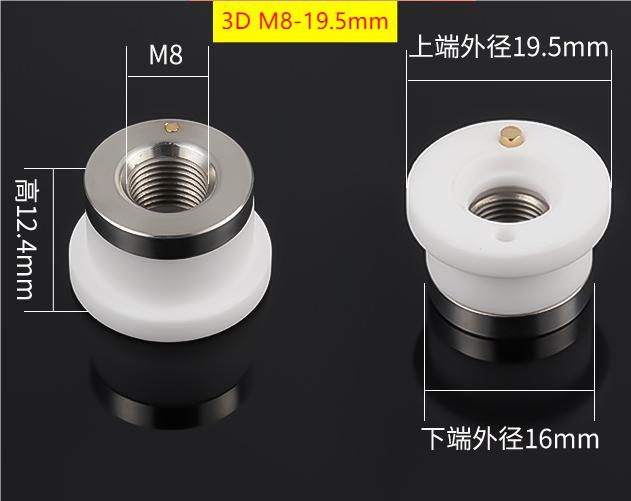

| Laser Height Adjuster | Capacitive sensor + laser ranging |

| Hole Position Correction | Auto Hole Patch |

| Cut File Formats | LMC, LMD, CNC, DXF, STC, TCM |

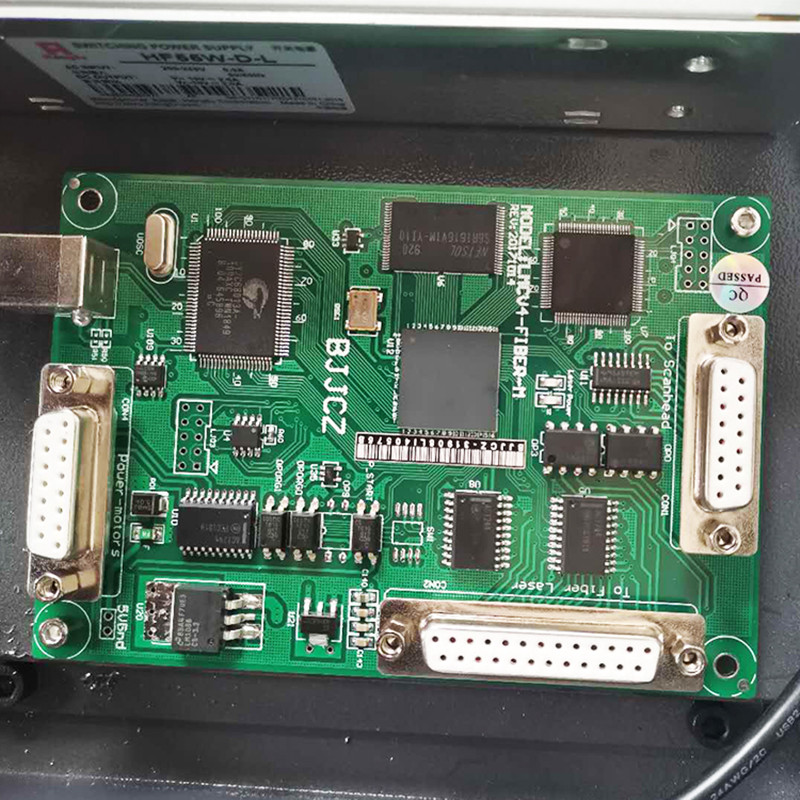

| Motion Controller | Radium Tech |

| XY Driver | Copley |

| Grating Ruler | Renishaw (0.1μm) |

| Guide Rail | HIWIN (Shangyin) |

| Servo Motor (ZU Axis) | Panasonic |

| Platform Material | Natural Granite |

| Machine Structure | Bridge-type |

| Software System | HKStudio (Upper Computer: Adamtech) |

| Input Power | 220V / 3KW |

| Air Pressure Requirement | 0.7 – 2.0 MPa |

| Auxiliary Cutting Gas | Oxygen (8–10Kg), Compressed Air (16Kg) |

| Operating Temperature | 10°C – 40°C |

| Humidity | Max 50% monthly average |

| Machine Dimensions (L×W×H) | 1640mm × 1380mm × 1500mm |

| Machine Weight | Approx. 2200Kg |

| Floor Load Requirement | < 800Kg/m² |

| Exhaust Fan Power Supply | 220V |

Precision Processing of 0.050mm Stainless Steel Thin Sheets

This laser cutting system is specially optimized for processing ultra-thin stainless steel sheets, particularly those with a thickness of 0.050mm. It delivers exceptional performance in applications requiring extreme precision, minimal thermal impact, and clean micro-hole cutting. The combination of a high-quality fiber laser source, CCD visual alignment, and granite platform ensures stable operation and micron-level consistency.

Key Capabilities with 0.050mm Stainless Steel Sheets:

Micro-hole drilling with diameter as small as 20μm

Burr-free cutting with smooth edges and no deformation

Ideal for SMT stencils, electronic filters, precision mesh, and fine medical device components

Stable positioning even with ultra-thin materials using vacuum adsorption and visual correction

High throughput, processing up to 22,000 holes per hour depending on the part geometry

The machine’s closed-loop control system and granite base design provide superior vibration resistance and thermal stability, which are critical for maintaining consistent results on such thin materials.