Precise Laser Cutting Process for Cutting 0.035mm Stainless Steel Electromagnetic Shielding (EMI/RFI Shielding)

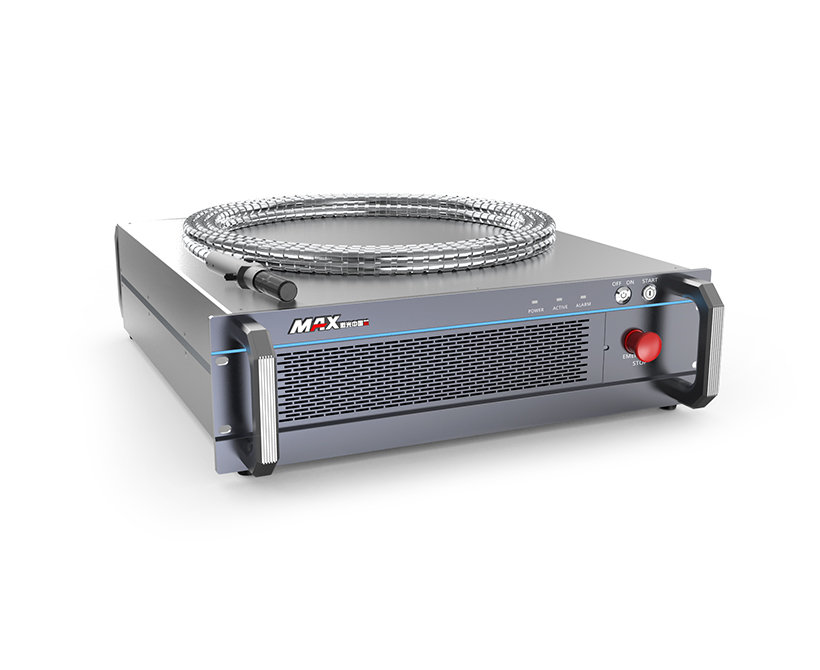

Electromagnetic Interference (EMI) and Radio Frequency Interference (RFI) shielding are crucial for protecting sensitive electronic components from external electromagnetic disturbances. 0.035mm stainless steel sheets are commonly used in EMI/RFI shielding applications due to their excellent conductivity, corrosion resistance, and durability. Precision laser cutting is an ideal method for processing these thin sheets, ensuring high accuracy and minimal material deformation.

Advantages of Laser Cutting for EMI/RFI Shielding

High Precision

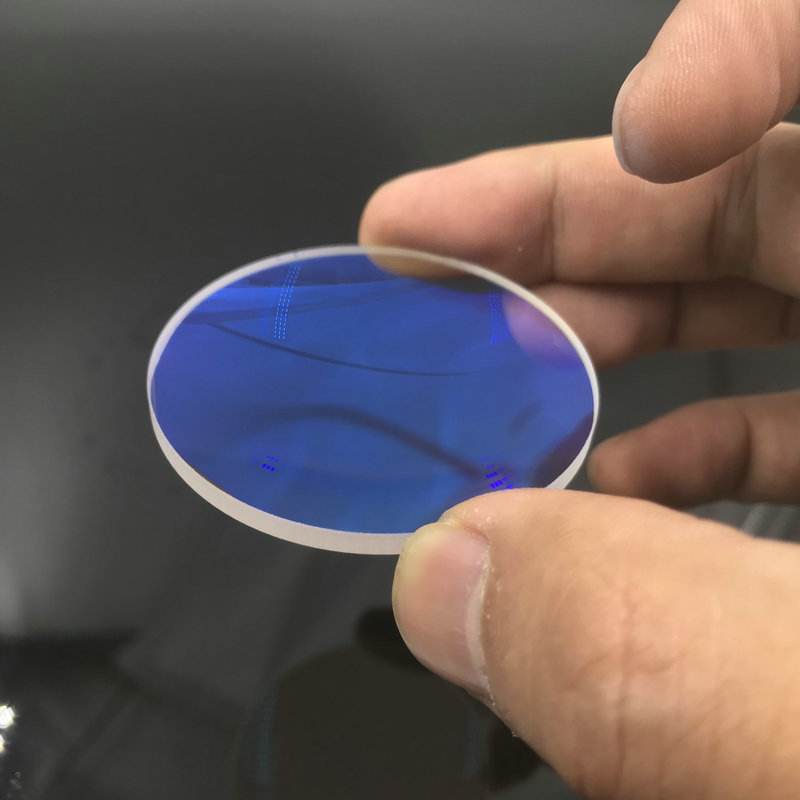

Laser cutting can achieve micro-level accuracy, which is essential for intricate shielding designs with complex patterns and perforations.

Minimal heat-affected zones (HAZ) prevent warping or material distortion.

Burr-Free & Smooth Edges

Non-Contact Processing

Customization & Flexibility

Minimal Material Waste

Applications of 0.035mm Stainless Steel EMI/RFI Shielding

Smartphones & Tablets – Shields microprocessors and RF components from interference.

Medical Equipment – Ensures accurate readings in MRI machines, ultrasound devices, and monitoring systems.

Automotive Electronics – Protects sensors, control modules, and GPS systems from electromagnetic interference.

Aerospace & Defense – Used in avionics, radar systems, and communication equipment.

5G & IoT Devices – Maintains signal integrity in wireless communication modules.

Conclusion

The precise laser cutting process for 0.035mm stainless steel EMI/RFI shielding offers unparalleled accuracy, smooth edges, and efficient material utilization. It is a key manufacturing technique for high-performance electronic shielding in industries such as telecommunications, aerospace, medical, and automotive sectors.