Vision Laser Marking Machine

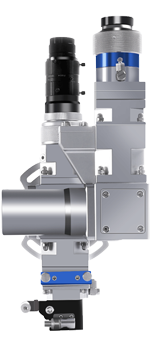

Camera and lens: 10 million camera + camera lens

Light source and light source controller: ring light source, 20cm diameter, 18cm inner diameter, equipped with diffuse reflector

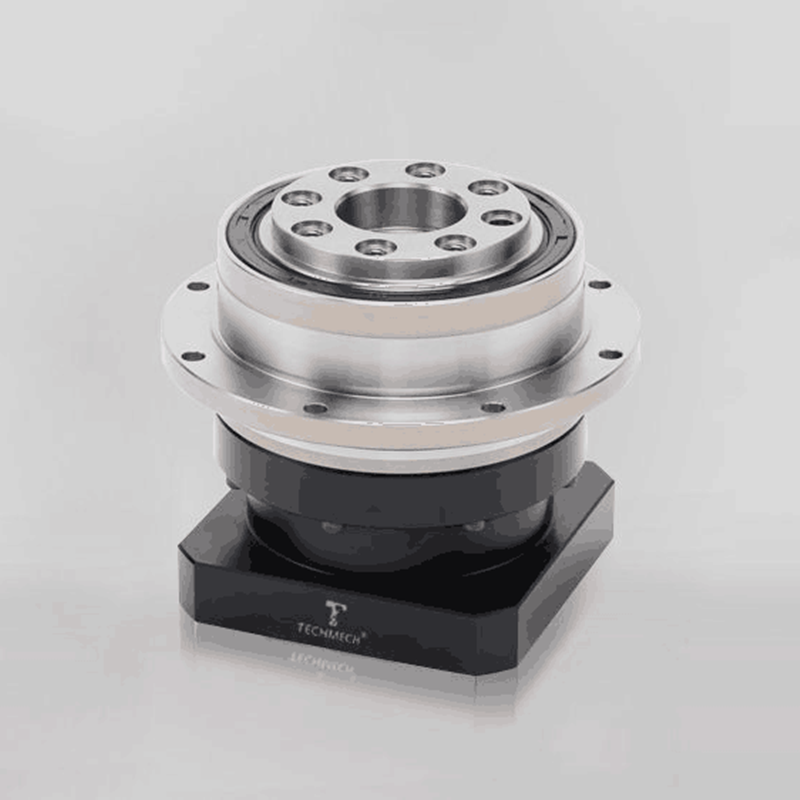

Motion control card: configure 4-axis motion card, which can control four motors, including adjusting focus, XY platform, etc.

Features:

■ 0~ 360° marking, no positioning jig

■ Fast recognition speed and accurate positioning

■ The efficiency is 3-5 times of ordinary marking machine

■ Positioning multiple products at one time, accurate marking

■ Various types of products, mixed marking with different contents

■ Simple operation, easy to learn

■ Simple configuration for automated production

Advantages of visual laser marking software:

In the process of product marking, traditional laser marking machines need to customize simple or complex fixtures for positioning, and the following problems will be encountered

1. Use of precision fixtures: New products require new precision fixtures, which increases the cost and prolongs the production cycle.

2. Simple jig is used: the marking efficiency of manual operation is low, and it will be misaligned if it is slightly inadvertent, which will affect the aesthetics of the product. When the traditional laser marking machine needs to realize automatic production, it has high requirements for mechanical precision, and making a complex automatic matching line can only be applied to one or a small number of products. For new products, a new production line needs to be made, which not only has a long cycle, but also is not conducive to the cost management of the factory.

Visual positioning laser marking system: realize fast positioning, mark multiple products at one time, and can also perform automatic feeding of the assembly line, and then perform visual positioning marking after rough positioning, saving labor, improving production efficiency, and easy to achieve compatibility with multiple products. Automated production lines save a lot of costs for factories.

Purpose of visual marking:

1. Save one labor station

2. Improve marking efficiency

3. Precise marking position

Configuration:

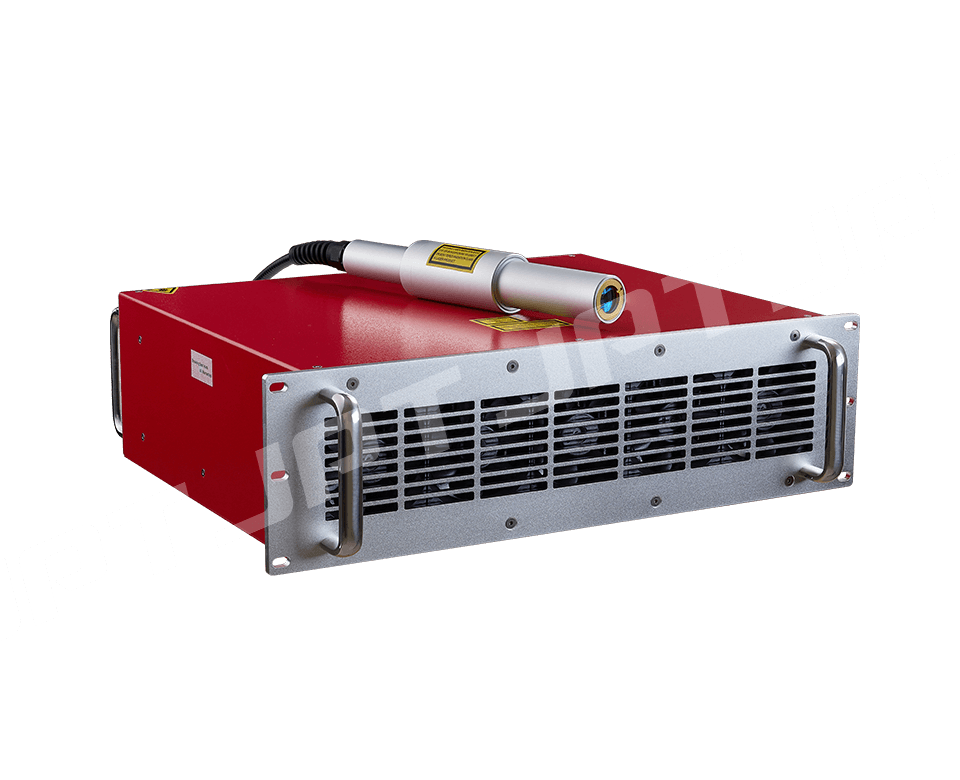

Laser marking machine: 1 set

Assembly line belt: 1

Industrial computer: 1 set

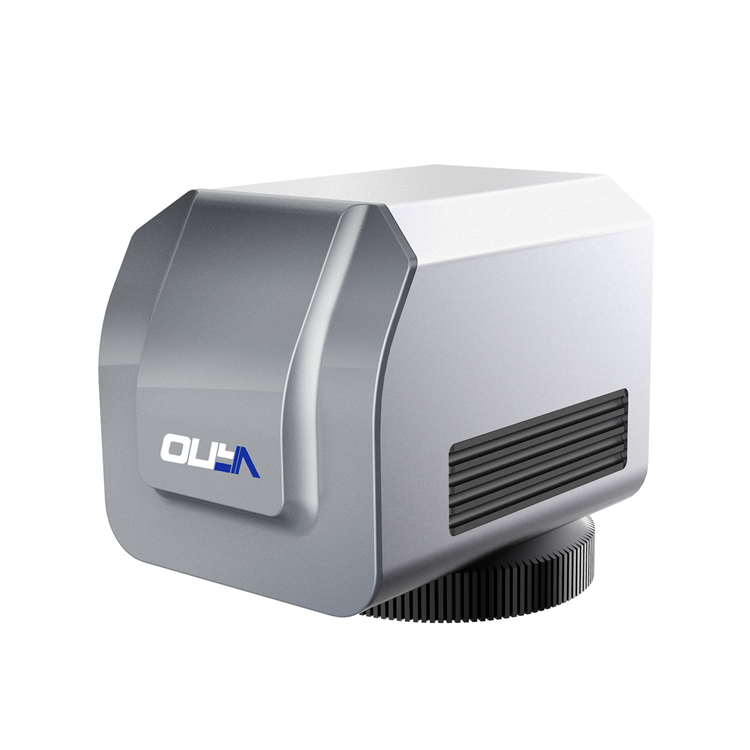

Vision system: 1 set

Z-axis electric marking cabinet: 1

Vision software features:

1. Automatically memorize the line speed, marking parameters, light source brightness, etc. of each product

2. Projection function, when editing product content, the content can be projected on the product,

You can see the position effect after marking

3. Statistics function, and generate marking log

4. When the product cannot be identified, it will prompt NG and give an alarm signal.

The pipeline stops until human intervention fixes the problem.

5. Equipped with automatic focal length memory function, it only takes 2 seconds to switch products.

After switching, the product automatically adjusts the marking focal length