detailed product information for the 3 NM³/h, 99.99% Nitrogen Gas Generator, a High Purity Nitrogen Gas Generator designed for industrial applications like laser cutting and laser welding:

Product Overview:

The ZHN-03 Nitrogen Gas Generator is a high-performance nitrogen generation system designed to produce ultra-pure nitrogen gas with a flow rate of 3 NM³/h and 99.99% purity. This system is ideal for applications such as laser cutting and laser welding, where high purity nitrogen is crucial for achieving high-quality cuts and welds.

Key Product Parameters:

| Feature | Specification |

| Model | ZHN-03 |

| Nitrogen Flow | 3 NM³/h (Controllable) |

| Nitrogen Purity | 99.99% |

| Inlet Pressure | 0.6-0.8 MPa |

| Nitrogen Pressure | ≤ 0.6 MPa |

| Power Consumption | 25W |

| Supply Voltage | AC 220V |

| Dimensions (L x W x H) | 700mm x 650mm x 1300mm |

Key Features and Benefits:

High Purity Nitrogen (99.99%):

Adjustable Nitrogen Flow (3 NM³/h):

Stable Inlet and Nitrogen Pressure:

Energy Efficient:

Compact Design:

The compact size (700mm x 650mm x 1300mm) makes it ideal for various industrial environments, including smaller workshops, production facilities, or as part of a larger automated system.

Low Maintenance and Reliable:

Real-Time Monitoring:

Applications:

Laser Cutting:

Nitrogen is used as an assist gas in laser cutting to improve cutting quality, especially for metals like stainless steel, carbon steel, and aluminum. It helps to produce clean, sharp edges and prevents oxidation of the cut area.

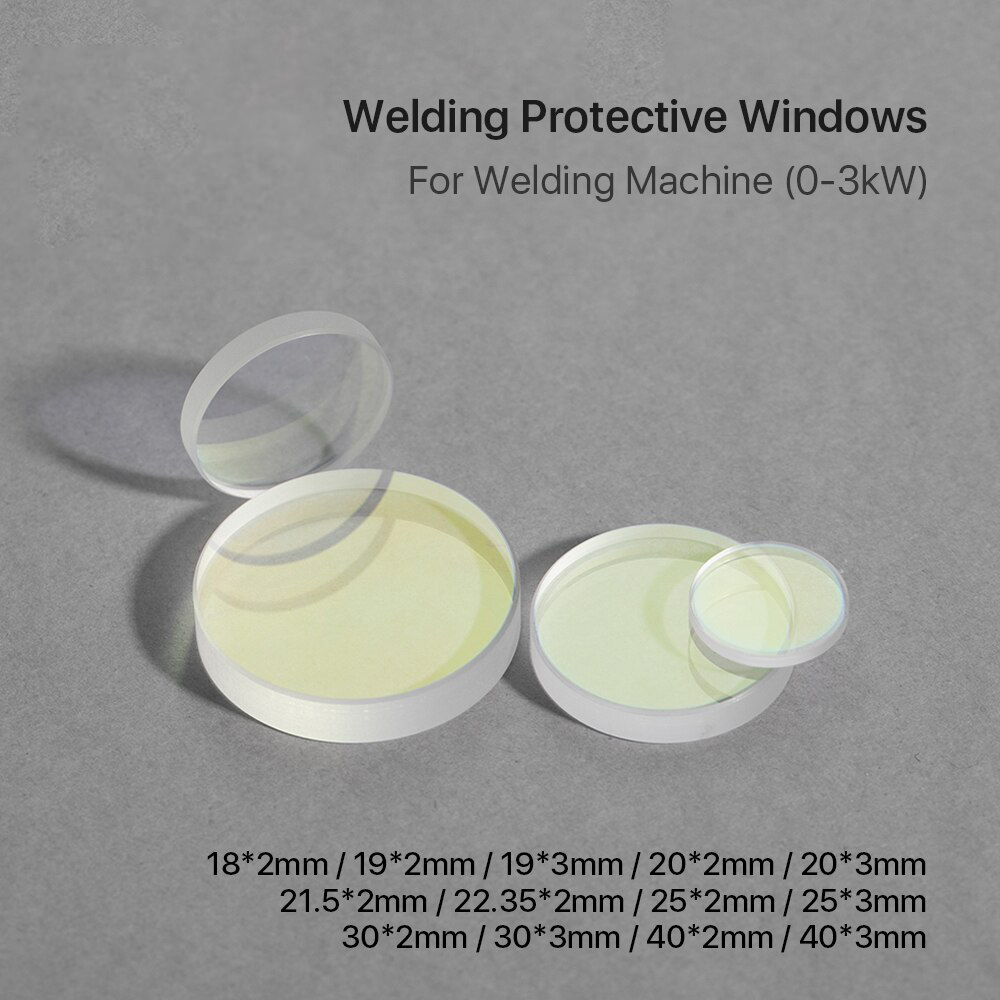

Laser Welding:

In laser welding, high-purity nitrogen is used to protect the weld pool from oxygen contamination, which can result in oxidation, porosity, and weak welds. Nitrogen helps produce cleaner, stronger, and more aesthetically pleasing welds.

Metal Fabrication:

Other Applications:

The generator can be used in electronics, pharmaceuticals, food packaging, and other industries requiring high-purity nitrogen for various processes.

How It Works:

The ZHN-03 uses Pressure Swing Adsorption (PSA) technology to separate oxygen from compressed air. Air is compressed, passed through molecular sieves, which adsorb oxygen, leaving high-purity nitrogen to flow out. The nitrogen is then used directly in applications such as laser cutting or laser welding.

Advantages:

Consistent High-Quality Nitrogen: With 99.99% purity, the generator ensures top-quality nitrogen production for sensitive industrial processes.

Flexible Flow Control: Adjustable flow rate (3 NM³/h) allows for tailored nitrogen output for different applications, such as varying material thicknesses and laser cutting speeds.

Cost-Effective: Onsite nitrogen generation eliminates the need for purchasing bottled nitrogen, reducing ongoing supply costs.

Low Energy Consumption: Operating at just 25W, it’s energy efficient, making it an environmentally friendly and cost-effective solution.

Durable and Reliable: The system’s robust design and PSA technology ensure long-lasting operation with minimal maintenance.

Compact and Space-Saving: With its compact size (700mm x 650mm x 1300mm), it fits in various industrial setups without requiring large space.