Precision Laser Cutting Services for PCB Soldering Shadow Mask

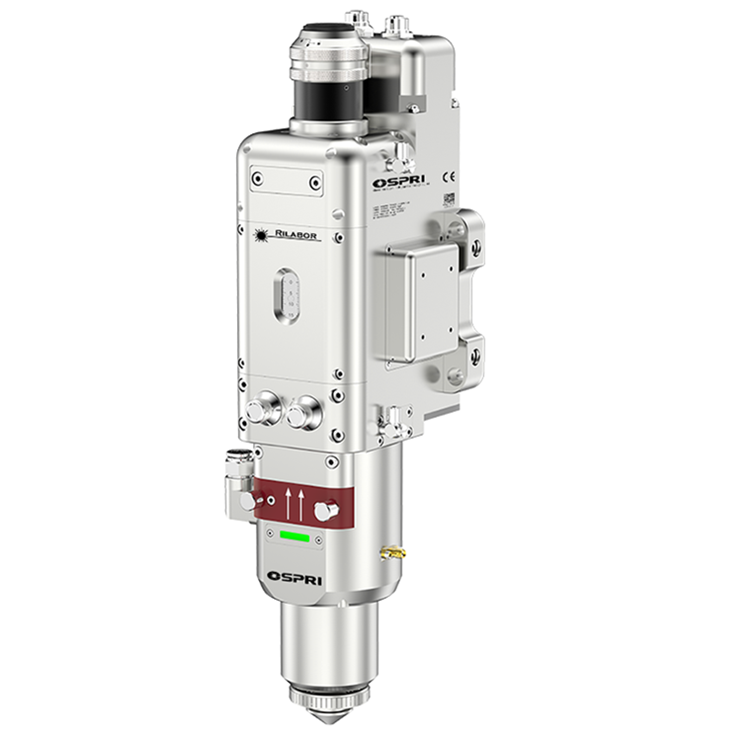

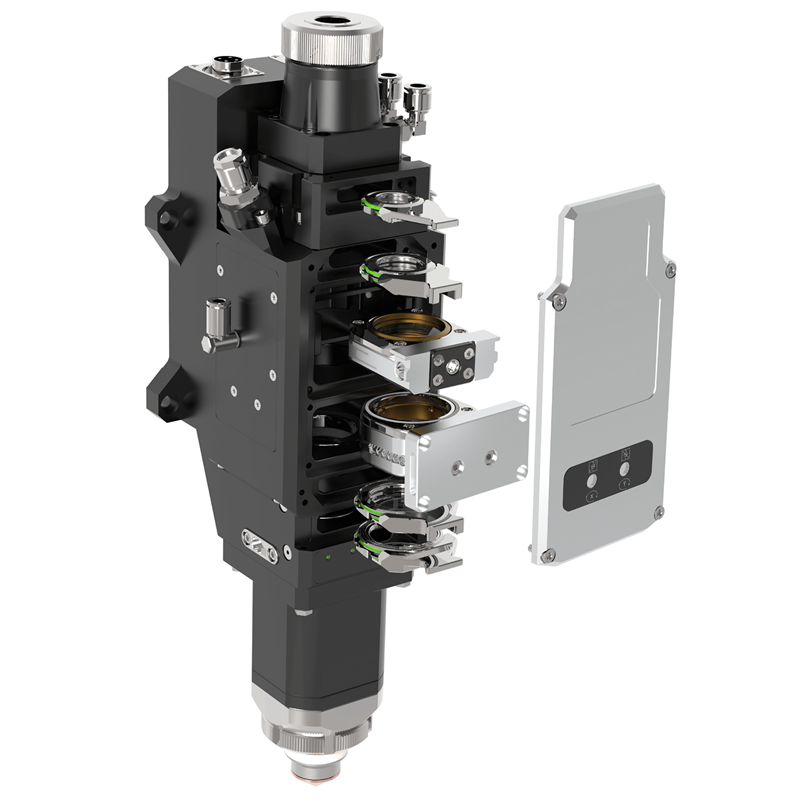

We provide precision laser cutting services for PCB soldering shadow masks, offering high accuracy, clean edges, and reliable performance to meet the stringent requirements of PCB soldering processes in electronics manufacturing.

Key Features:

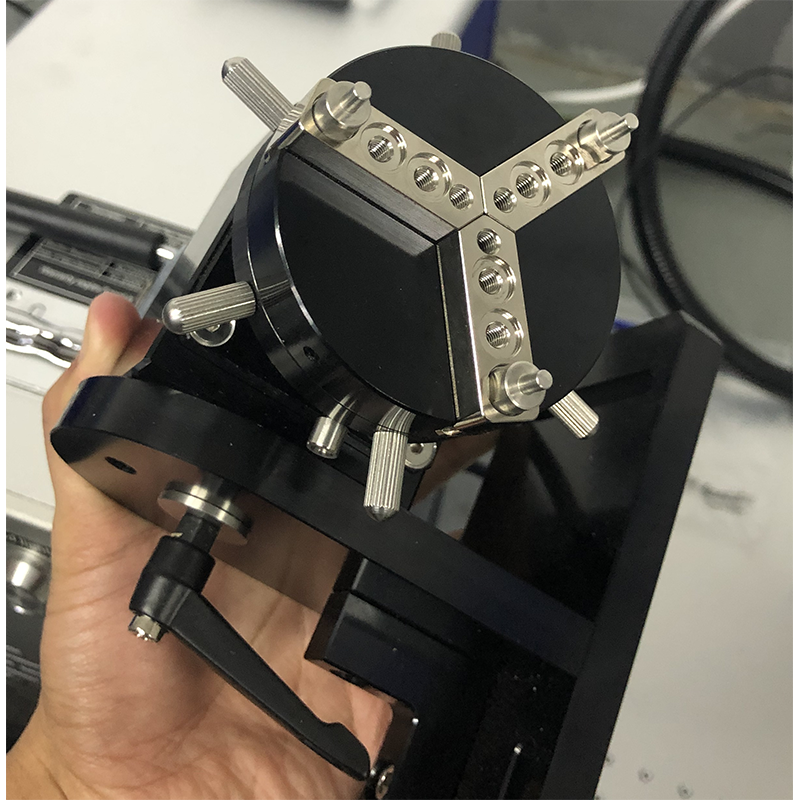

Micro-Precision Cutting: Achieving precise apertures and intricate patterns for accurate solder paste deposition during PCB assembly.

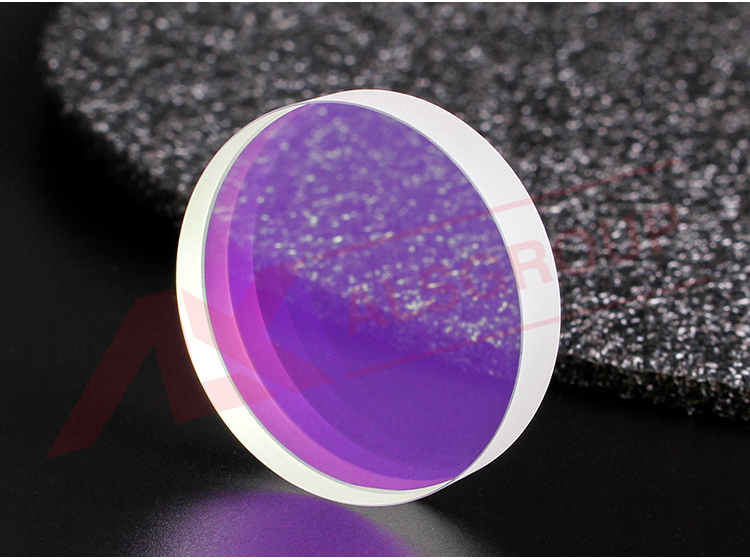

Burr-Free Edges: Ensuring clean, defect-free edges to prevent soldering issues and enhance overall process quality.

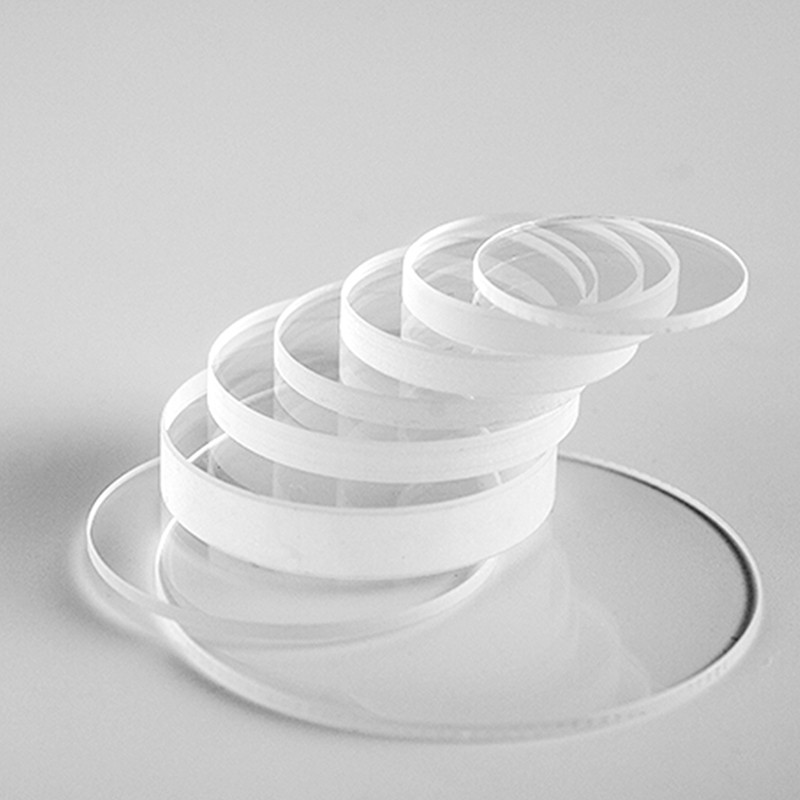

Stress-Free Finishing: Maintaining the dimensional stability of the mask with no distortion or warping after cutting.

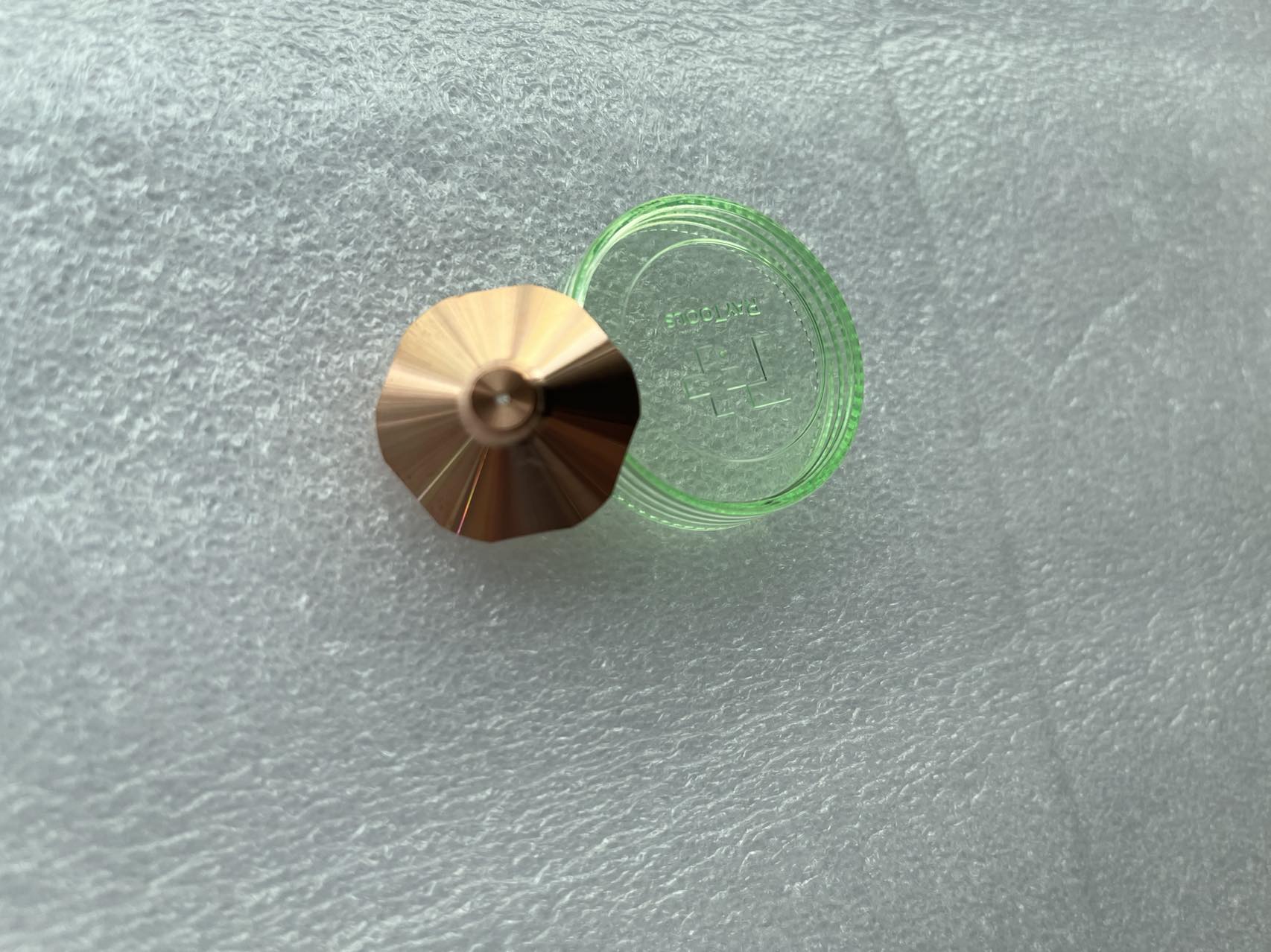

Material Specialization: Working with durable and corrosion-resistant materials such as stainless steel, Nickel, and high-performance alloys that ensure long-lasting stencils.

High-Aperture Accuracy: Delivering precise hole sizes and uniform aperture spacing with tolerance control as tight as ±5μm.

Customization: Supporting complex geometries and specific design requirements for various PCB sizes, pitches, and layouts.

Applications:

Solder paste printing for PCB assembly in electronics manufacturing.

Shadow masks for high-density and fine-pitch PCBs.

Precision stencil masks for advanced soldering processes in automated SMT lines.

Microelectronics and high-performance PCB production.

Our advanced laser cutting technology and dedication to unmatched precision ensure that your PCB soldering shadow masks meet the highest standards of quality and performance.