Laser Cutting for 0.080mm Metal Thin Sheets - Product Applications

Our precision laser cutting machines are ideal for processing 0.080mm thin metal sheets, including stainless steel, aluminum, and copper. These machines are specifically designed for high-precision cutting of thin metals, providing clean, accurate cuts without material distortion. The laser cutting process ensures that even intricate and detailed patterns can be achieved with ease.

Machine Applications for 0.080mm Thin Metal Sheets

The laser cutting technology used for 0.080mm thin metal sheets is suitable for a variety of industries that demand precise, small-scale, or high-volume production of thin metal components.

Key Products Manufactured Using 0.080mm Metal Sheets:

| Industry | End Products |

| Electronics | - Micro connectors for circuit boards and electronics |

| - Precision components for mobile phone assembly |

| Medical Devices | - Microfluidic chips for diagnostics and lab-on-a-chip devices |

| - Thin surgical tools such as scalpels and surgical guides |

| Automotive | - Gaskets and seals for automotive engines and components |

| - Small automotive sensors for electric vehicle applications |

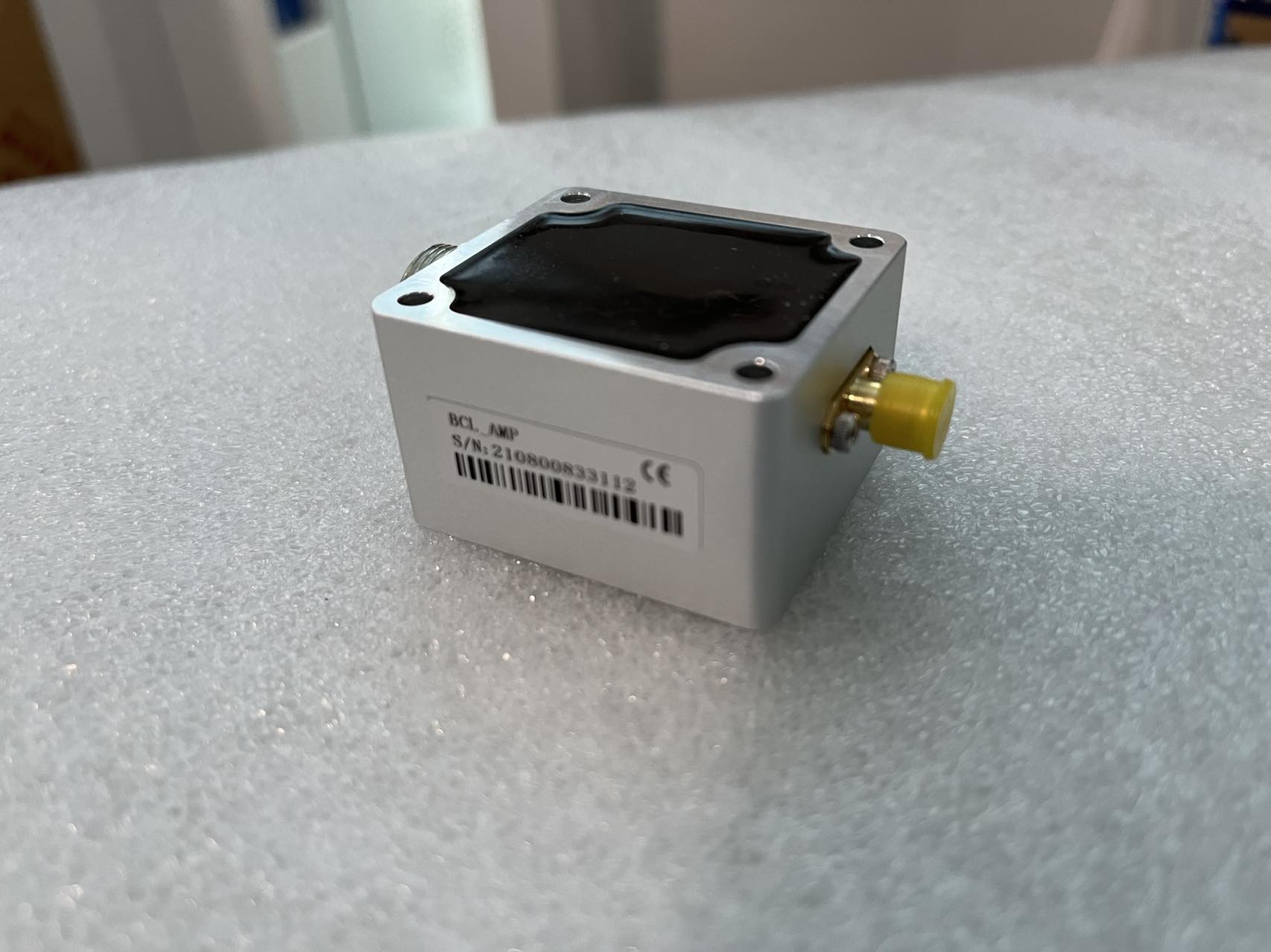

| Communication | - RF components for antennas and signal shielding in communication devices |

| Aerospace & Defense | - Thin metal brackets for aerospace structures |

| - Precision parts for aircraft sensors and systems |

| SMT / PCB Industry | - Stencils for solder paste application on circuit boards |

| Filtration | - Micro-perforated screens for filtration applications |

| - Filters used in air, liquid, and gas systems |

✅ Why Choose Laser Cutting for 0.080mm Metal Sheets?

High Precision: Achieve detailed cuts with minimal kerf width and high accuracy, especially for thin materials.

No Mechanical Stress: The laser cutting process is non-contact, ensuring that there is no mechanical stress, warping, or deformation on the material.

Fast Cutting Speeds: The process can handle up to 22,000 holes per hour, making it ideal for high-volume production.

Versatility: Capable of cutting various metals, including stainless steel, aluminum, and copper, across different thicknesses, especially 0.080mm thin sheets.

Fine Edge Quality: Provides clean, smooth edges with minimal post-processing required.

Example Applications

Electronics Industry:

0.080mm thin stainless steel is often used to create precision connectors for smartphones, tablets, and other compact devices. The thinness allows for flexibility and precision in the delicate designs required for electronics.

Medical Devices:

Automotive:

Machine Specifications for Processing 0.080mm Metal Sheets

| Feature | Specification |

| Laser Power | 100W–200W (IPG Fiber Laser) |

| Cutting Speed | Up to 22,000 holes/hour |

| Positioning Accuracy | ±2 μm |

| Repeatability | ±2 μm |

| Cutting Line Width | 0.02–0.03 mm |

| Max Cutting Thickness | 1.0 mm (Ideal for 0.080mm metal sheets) |

| Working Area | 650mm × 650mm |

| Power Supply | 220V, 3KW |

| Weight | Approx. 2200Kg |

This machine's precision and efficiency make it ideal for producing high-quality, small-scale components from 0.080mm metal sheets, suitable for industries such as electronics, automotive, aerospace, medical devices, and more.