Precise Laser Cutting Process for Cutting 0.045mm Stainless Steel Micro Connectors

Micro connectors are essential components in electronics, medical devices, aerospace, and telecommunications. These connectors require ultra-precise, burr-free, and distortion-free processing, which makes laser cutting the preferred manufacturing method for 0.045mm stainless steel micro connectors.

Advantages of Laser Cutting for Micro Connectors

Ultra-High Precision

Achieves micron-level accuracy, ensuring tight tolerances for miniature components.

Supports intricate geometries and fine details for complex connector designs.

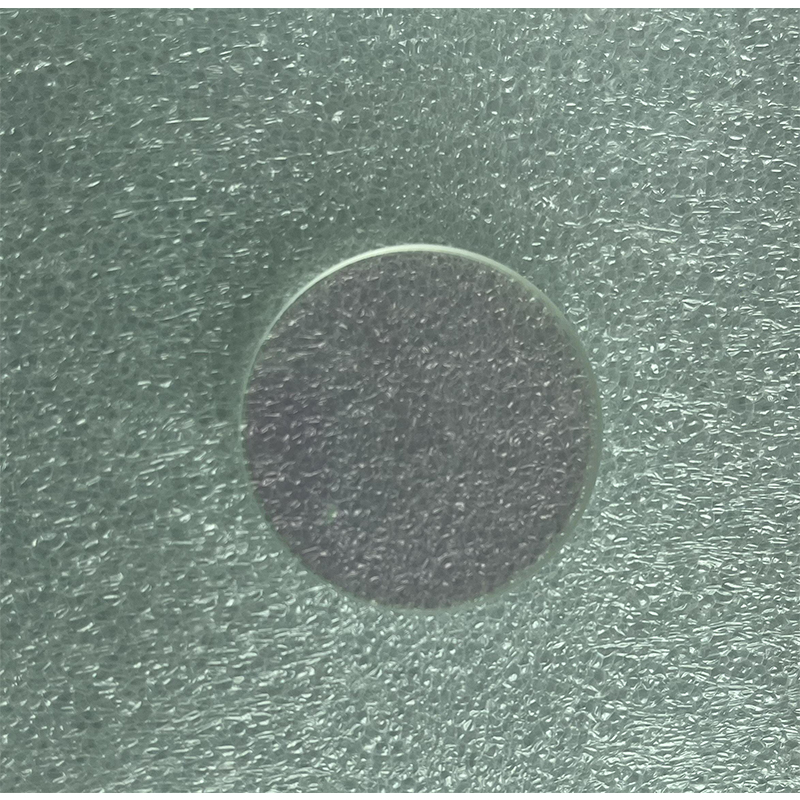

Burr-Free & Clean Cutting

Minimal Heat-Affected Zone (HAZ)

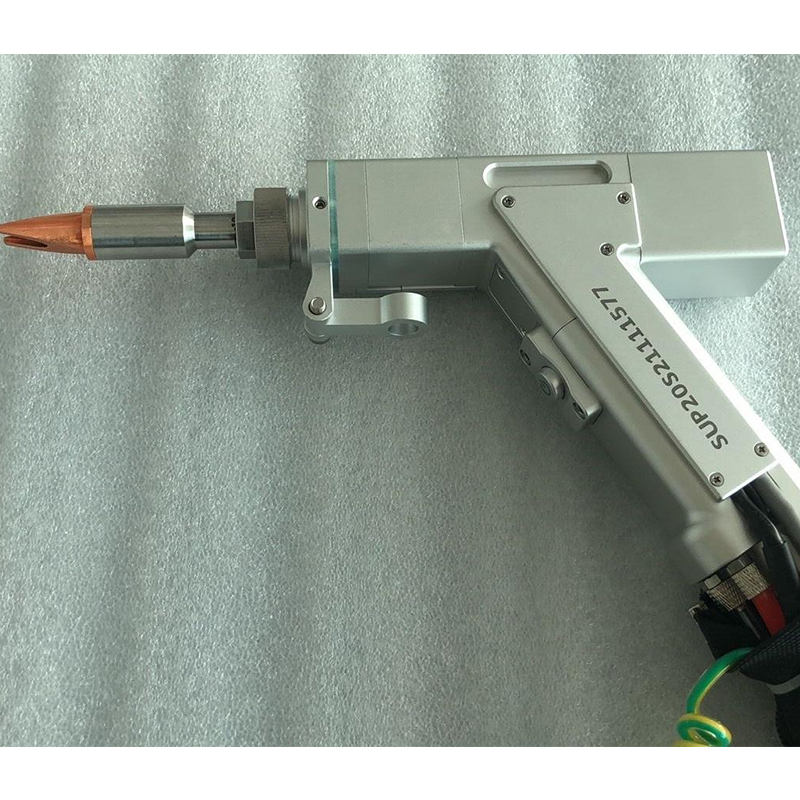

Non-Contact Processing

High-Speed & Efficient Production

Customizable Designs

Applications of 0.045mm Stainless Steel Micro Connectors

Medical Device Connectors – Used in implantable electronics, diagnostic equipment, and surgical tools.

Aerospace & Defense – High-reliability micro connectors for avionics and military communication systems.

5G & IoT Devices – Ensures high-speed data transfer in compact electronic devices.

Automotive Electronics – Essential for ADAS, LiDAR, and electric vehicle battery connections.

Wearable Technology – Miniaturized connectors for smartwatches, fitness trackers, and AR/VR devices.

Conclusion

The precise laser cutting process for 0.045mm stainless steel micro connectors provides unmatched accuracy, burr-free edges, and efficient production, making it the ideal solution for high-performance electronic components in medical, aerospace, automotive, and telecommunications industries.