Laser Cutting for 0.090mm Metal Thin Sheets - Product Applications

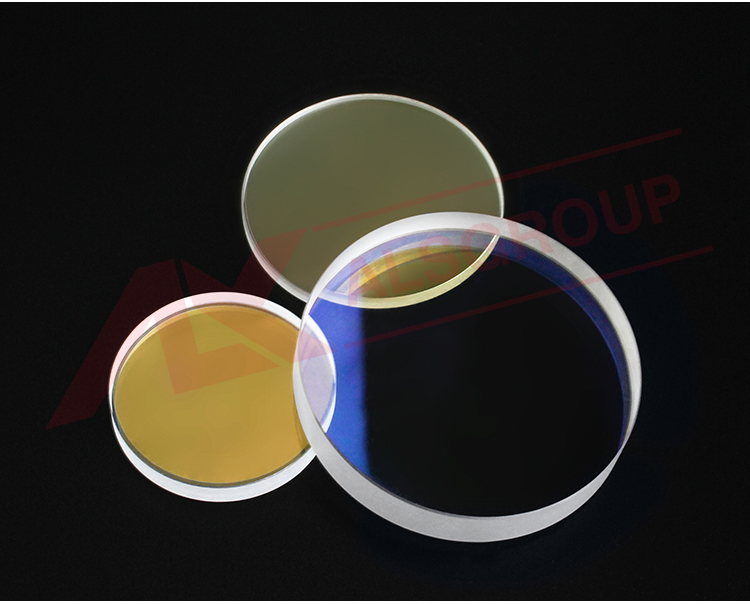

Laser cutting technology is the optimal solution for processing 0.090mm thin metal sheets, including stainless steel, aluminum, and copper. The precision and versatility of laser cutting ensure clean, accurate cuts with minimal heat-affected zones, which is crucial for achieving high-quality finishes on such thin metal sheets. The process is ideal for applications in industries requiring fine detailing and complex designs on thin materials.

Advantages of Laser Cutting for 0.090mm Thin Metal Sheets

High Precision and Accuracy: Laser cutting provides excellent accuracy, ensuring that each cut is precise within ±5μm. This level of detail is crucial for working with 0.090mm thin metal sheets, where even a slight deviation can affect the overall product quality.

Clean and Smooth Edges: Laser cutting leaves smooth edges with minimal burr formation, which reduces the need for post-processing and improves the quality of the finished product, especially important for delicate components.

Minimal Material Waste: The narrow laser beam results in very little waste, making it an economical choice for cutting thin sheets like 0.090mm metal. This efficient material usage helps lower production costs.

No Mechanical Stress: Since the laser process does not involve direct contact with the material, there is no mechanical stress applied. This prevents distortion and warping that could occur with traditional cutting methods.

Versatile for Various Materials: Laser cutting can easily handle different materials such as stainless steel, aluminum, and copper. This versatility allows manufacturers to choose the best material for each specific application without worrying about equipment limitations.

High Speed and Efficiency: The high cutting speed ensures that even intricate designs can be processed quickly, making laser cutting an ideal choice for high-volume production environments.

Key Products Manufactured from 0.090mm Thin Metal Sheets Using Laser Cutting

Laser cutting technology for 0.090mm metal sheets is widely used in a variety of industries that require precision, high-quality finishes, and intricate designs. Here are some of the key products manufactured using laser cutting for 0.090mm metal sheets:

| Industry | End Products |

| Electronics | - Micro connectors for circuit boards |

| - Precision components for mobile phone assemblies |

| Medical Devices | - Precision surgical tools and instruments |

| - Thin metal components for medical devices such as stents and catheters |

| Automotive | - Small components like brackets, gaskets, and clips for automotive parts |

| - Thin metal parts for engine and electrical systems |

| Aerospace | - Lightweight brackets and supports for aircraft and spacecraft |

| - Thin metal parts used in aerospace components and control systems |

| Communication | - RF components for antennas and signal devices |

| - Precision components for communication equipment |

| Energy | - Precision metal parts for solar panel frames and energy components |

| Defense | - Laser-cut shields and sensors for military equipment |

| Consumer Goods | - Thin metal panels and frames for consumer products |

✅ Why Choose Laser Cutting for 0.090mm Metal Sheets?

High Precision and Fine Detailing: Laser cutting offers unparalleled precision, which is essential for the fine tolerances required in industries such as electronics and medical devices.

Fast Production Speed: Laser cutting allows for high-speed processing, enabling efficient production even for intricate designs.

No Contact, No Distortion: The non-contact nature of laser cutting ensures no mechanical stress is applied, which prevents distortion and warping in 0.090mm metal sheets.

Cost-Effective: With minimal waste and reduced need for post-processing, laser cutting is an economical method for producing high-quality components.

Versatile for Various Materials: Laser cutting can handle a wide range of materials, making it suitable for different industries and applications, from medical devices to automotive parts.

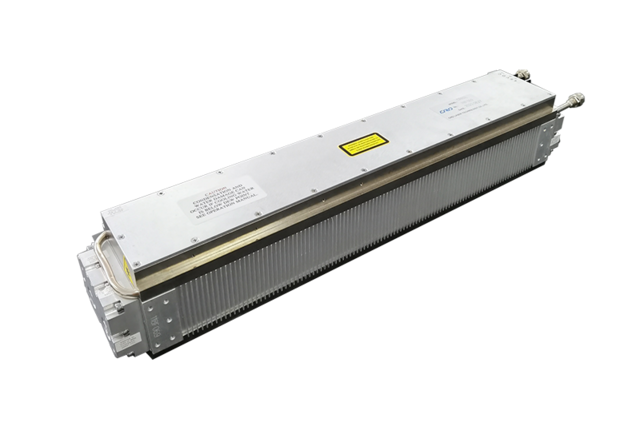

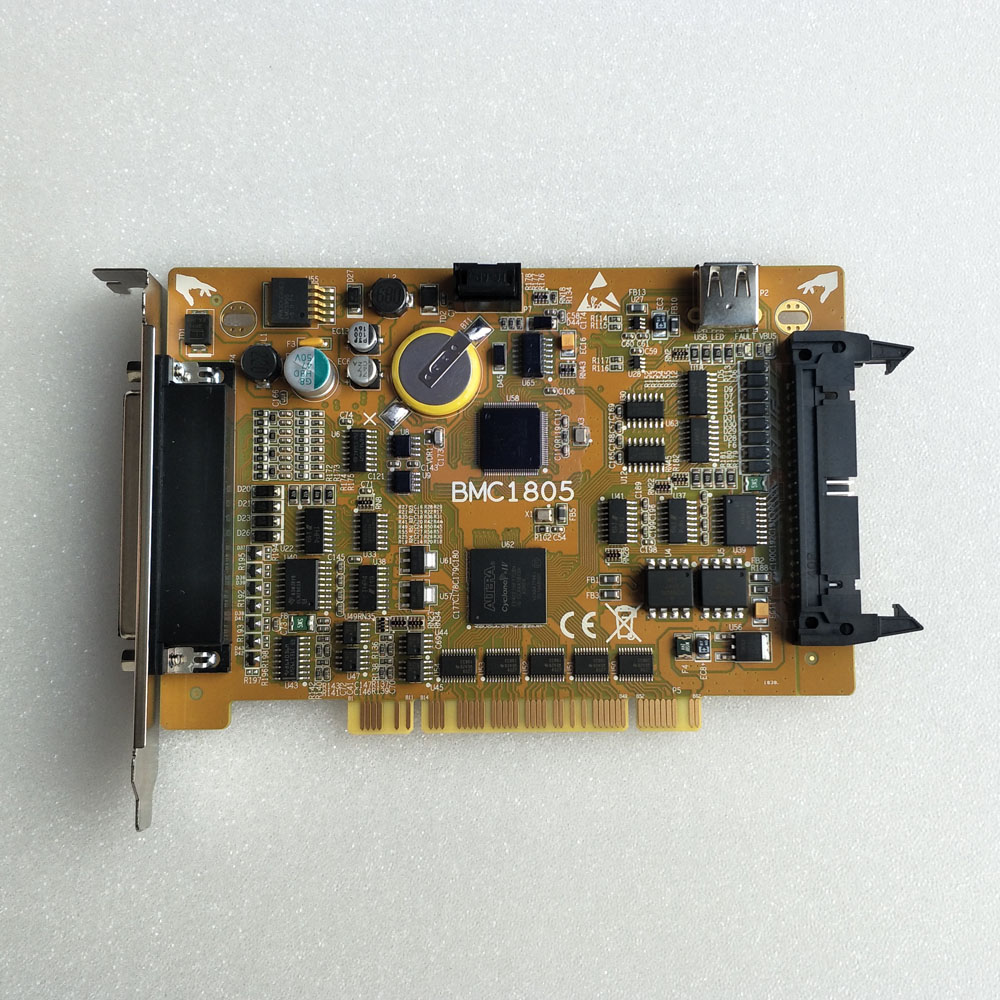

Machine Specifications for Processing 0.090mm Metal Sheets

| Feature | Specification |

| Laser Power | 100W–200W (IPG Fiber Laser) |

| Cutting Speed | Up to 22,000 holes/hour |

| Positioning Accuracy | ±2 μm |

| Repeatability | ±2 μm |

| Cutting Line Width | 0.02–0.03 mm |

| Max Cutting Thickness | 1.0 mm (Ideal for 0.090mm thin sheets) |

| Working Area | 650mm × 650mm |

| Power Supply | 220V, 3KW |

| Weight | Approx. 2200Kg |

Conclusion

Laser cutting technology is the preferred method for processing 0.090mm thin metal sheets in industries requiring high precision, fine detailing, and clean cuts. From electronics and medical devices to automotive and aerospace, laser cutting ensures that even the most intricate designs are executed with minimal material waste and high efficiency. Whether you are producing micro connectors or lightweight aerospace parts, laser cutting offers the ideal solution for achieving superior results with reduced production time.