ZHN-01 Small Nitrogen Gas Generator, designed specifically for laser cutting and laser welding applications, offering 99.99% nitrogen purity and a 1 NM³/h flow rate.

Product Overview:

The ZHN-01 is a small nitrogen gas generator designed to produce high-purity nitrogen (99.99%) with a 1 NM³/h flow rate. This unit is compact and efficient, making it ideal for applications that require high-quality nitrogen gas, such as laser cutting and laser welding. It utilizes Pressure Swing Adsorption (PSA) technology, ensuring reliable performance with minimal maintenance.

Product Parameters:

| Feature | Specification |

| Model | ZHN-01 (Embedded) |

| Nitrogen Flow | 1 NM³/h (Controllable) |

| Nitrogen Purity | 99.99% |

| Inlet Pressure | 0.6-0.8 MPa |

| Nitrogen Pressure | ≤ 0.6 MPa |

| Power Consumption | 15W |

| Supply Voltage | AC 220V |

| Dimensions (L x W x H) | 550mm x 165mm x 690mm |

Key Features and Benefits:

High Purity Nitrogen (99.99%):

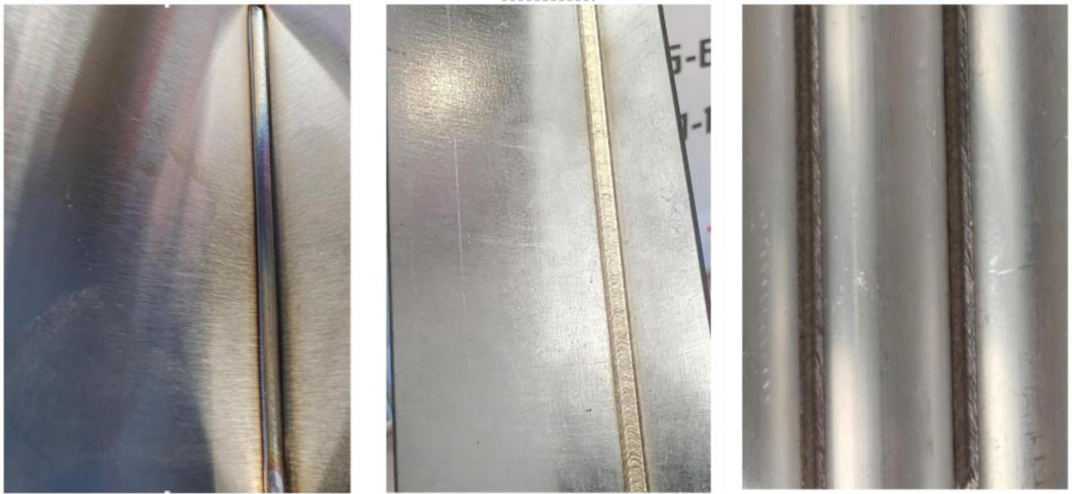

The ZHN-01 produces high-purity nitrogen (99.99%), which is ideal for critical applications like laser cutting and laser welding, where oxygen must be excluded to prevent oxidation and ensure clean, high-quality results.

Adjustable Nitrogen Flow (1 NM³/h):

Real-Time Monitoring:

Programmable Time Relay:

Compact Design:

The small and compact design (550mm x 165mm x 690mm) makes the ZHN-01 suitable for smaller workspaces or applications where space is limited, such as small workshops, laboratories, or on-site installations.

Low Power Consumption:

Easy Installation:

Applications:

How It Works:

The ZHN-01 utilizes PSA (Pressure Swing Adsorption) technology to separate nitrogen from air. Compressed air is passed through carbon molecular sieves that adsorb oxygen and other impurities, allowing only nitrogen to pass through and be delivered at 99.99% purity. The nitrogen is then directed to the outlet for use in applications like laser cutting and laser welding.