air-cooled laser clean system.pdf

air-cooled laser clean system.pdf

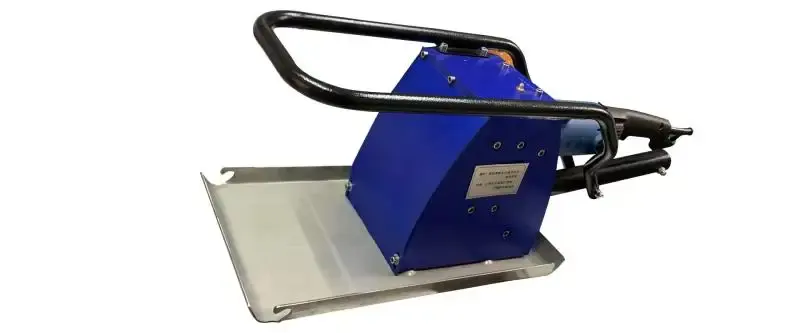

Handheld Laser Cleaning Machine

Features:

◆Integrated structure of all-in-one machine, ergonomic design

◆ Multifunctional laser cleaning control system

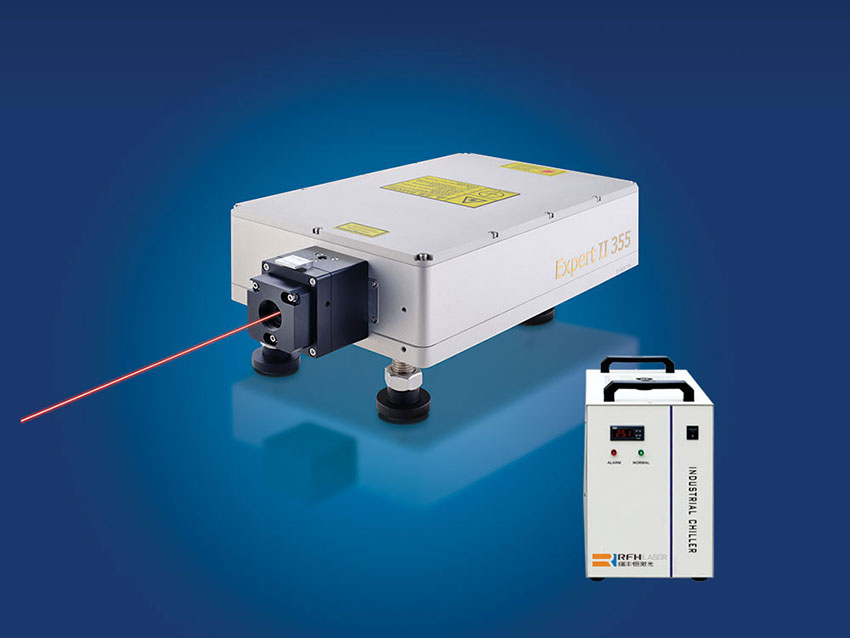

◆Optional MOPA pulse or flat top pulse fiber laser

◆Dual temperature and dual control water cooling system to ensure long-term operation

◆Derusting and decontamination on the surfaces of molds, metal products, spraying, etc.

swing pattern:

Eight kinds of swing graphics cleaning modes, cleaning is more clean, suitable for many scenes. Swing mode: X/Y double-axis swing; adjustable swing amplitude: 0~50mm (width)

Process application:

It is mainly used for laser cleaning and laser pretreatment of metal surfaces such as molds, metal products, ships, automobiles, medical equipment, sheet metal/spraying, etc. After laser cleaning the oil stain and oxide layer on the surface of metal materials before welding, the welding quality and weld firmness can be significantly improved.

Equipment advantages:

More environmentally friendly: no need to use any chemicals and cleaning fluids, and the generated pollutant particles and gases can be collected and purified by portable exhaust fans;

No damage: The laser adopts non-grinding and non-contact cleaning methods, and a short-term impact will not heat the metal surface and cause no damage to the substrate;

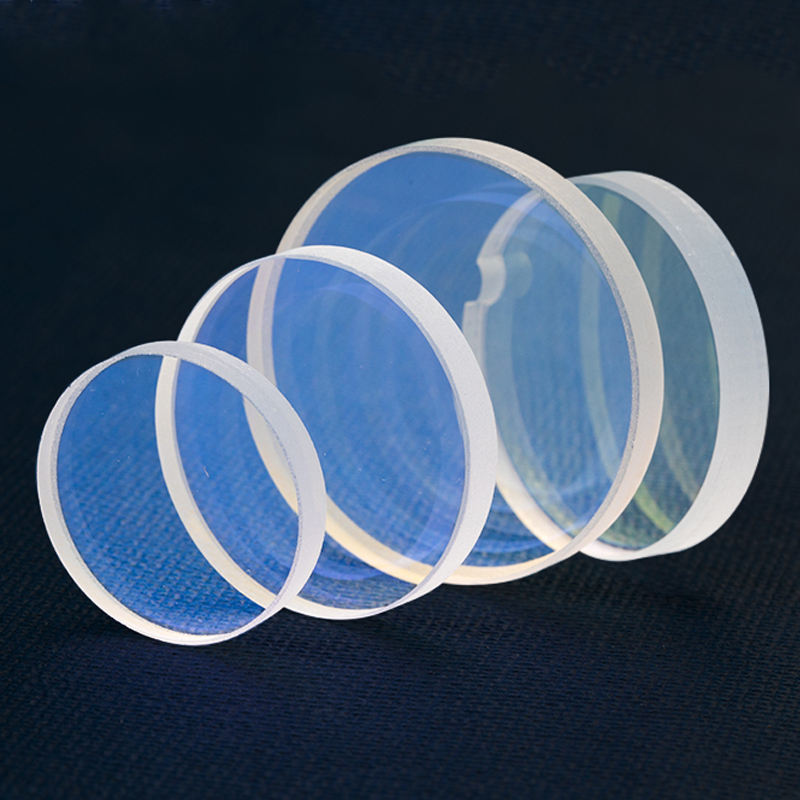

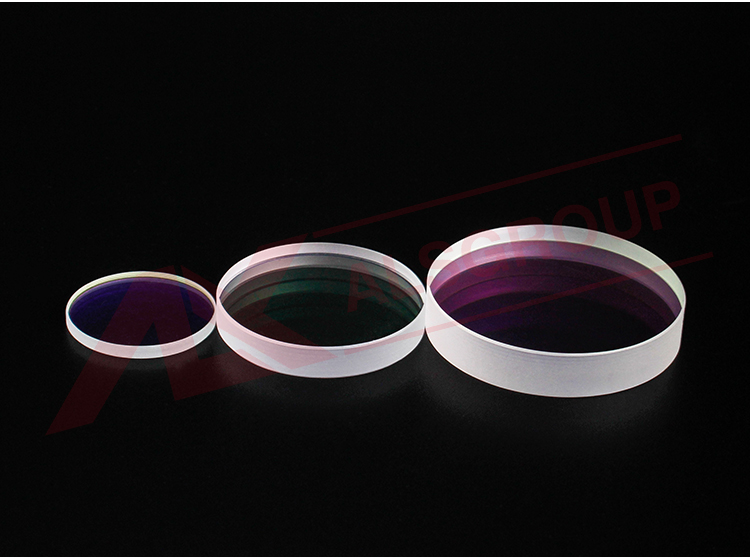

Low cost: no consumables are consumed during the use of the laser cleaning machine, the operating cost is low, and the lens only needs to be cleaned or replaced regularly in the later stage, the maintenance cost is low, and it is close to maintenance-free;

Easy to clean: The built-in scanning galvanometer controls the light spot to move at a high speed, which is convenient for cleaning the corner parts that are difficult to reach by traditional cleaning methods such as special-shaped parts, holes, and grooves;

Wide range of materials: Laser cleaning can almost remove various types of contaminants on the surface of various materials, achieving a cleanliness that cannot be achieved by conventional cleaning.

Automation: It can be integrated with CNC machine tools or robots to implement remote control and cleaning, realize the automation of equipment, form product assembly line operations, and operate intelligently.