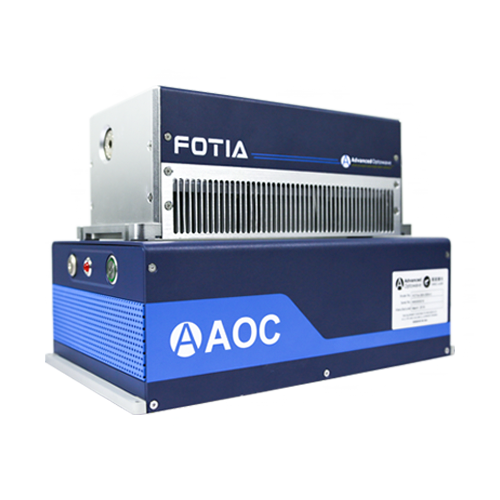

Laser Chiller > Fiber Laser Chiller > DLY-2500W-AD2

Application Range: Suitable for fiber lasers with a power range of 2000W to 2500W, cooling capacity of 8500W.

Features and Functions:

High-quality refrigeration components with fan speed control and electronic expansion valve energy regulation, achieving temperature control accuracy of ±0.5°C to ±1.0°C.

Equipped with RS485 communication function for remote monitoring via PC.

Includes dual protections for high/low temperature and high/low pressure, with intelligent anti-freeze protection.

Features flow display function with adjustable flow alarm values as per customer requirements.

Dual water temperature design: Automatic constant temperature function with two different set temperatures to meet varied demands. Dual signal output protection ensures one water temperature meets the cooling needs of the laser, while the other aligns with ambient temperature for laser output cooling.

Double water filter protection: Equipped with pure water and deionized water filters for enhanced equipment safety. Also includes conductivity detection device and signal output, with adjustable conductivity alarm values to effectively protect the laser.

These features make the DLY-2500W-AD2 suitable for efficiently cooling fiber lasers within the specified power range, offering multiple protection features and remote monitoring capabilities for industrial applications.

A 2000W to 2500W fiber laser chiller is specifically designed to cool fiber lasers within this power range. Here are some key aspects typically associated with such chillers:

Cooling Capacity: The chiller's cooling capacity is matched to handle the heat output of fiber lasers ranging from 2000W to 2500W. This ensures efficient cooling to maintain optimal operating temperatures.

Temperature Control: Precision temperature control is crucial to ensure the fiber laser operates within its specified temperature range, typically with accuracies ranging from ±0.5°C to ±1.0°C.

Refrigeration System: It includes high-quality refrigeration components such as compressors, evaporators, condensers, and pumps to circulate and cool the coolant (usually water or a water-glycol mixture).

Safety Features: These chillers often come with built-in protections against high/low temperatures, high/low pressures, and features like anti-freeze protection to safeguard the equipment and ensure reliable operation.

Communication and Monitoring: Many models are equipped with RS485 communication capability for remote monitoring and control via PC. This allows operators to monitor temperature levels, adjust settings, and receive alerts remotely.

Dual Water Temperature Design: Some advanced models may feature dual water temperature settings to accommodate different cooling requirements, ensuring optimal performance of both the fiber laser and its output optics.

Water Filtration and Monitoring: They often include water filtration systems (such as pure water and deionized water filters) and conductivity monitoring to maintain water quality and protect the laser from contaminants.

Overall, a chiller designed for 2000W to 2500W fiber lasers plays a critical role in maintaining stable and efficient operation, prolonging the lifespan of the laser system, and ensuring consistent performance in industrial applications such as laser cutting, welding, and marking.