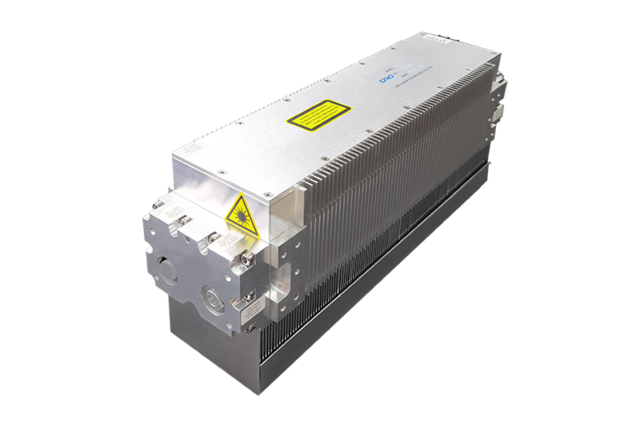

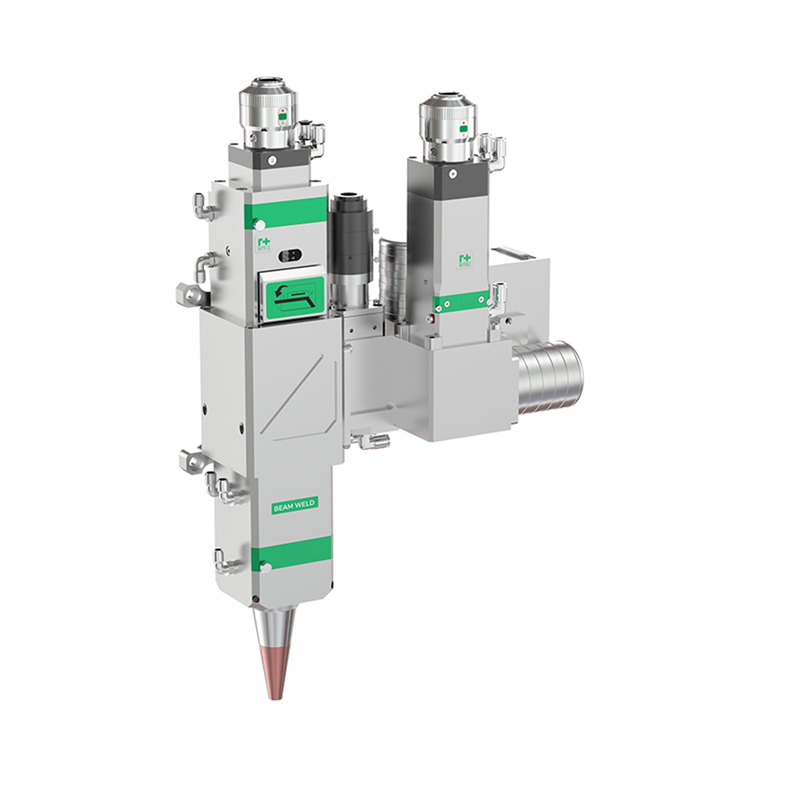

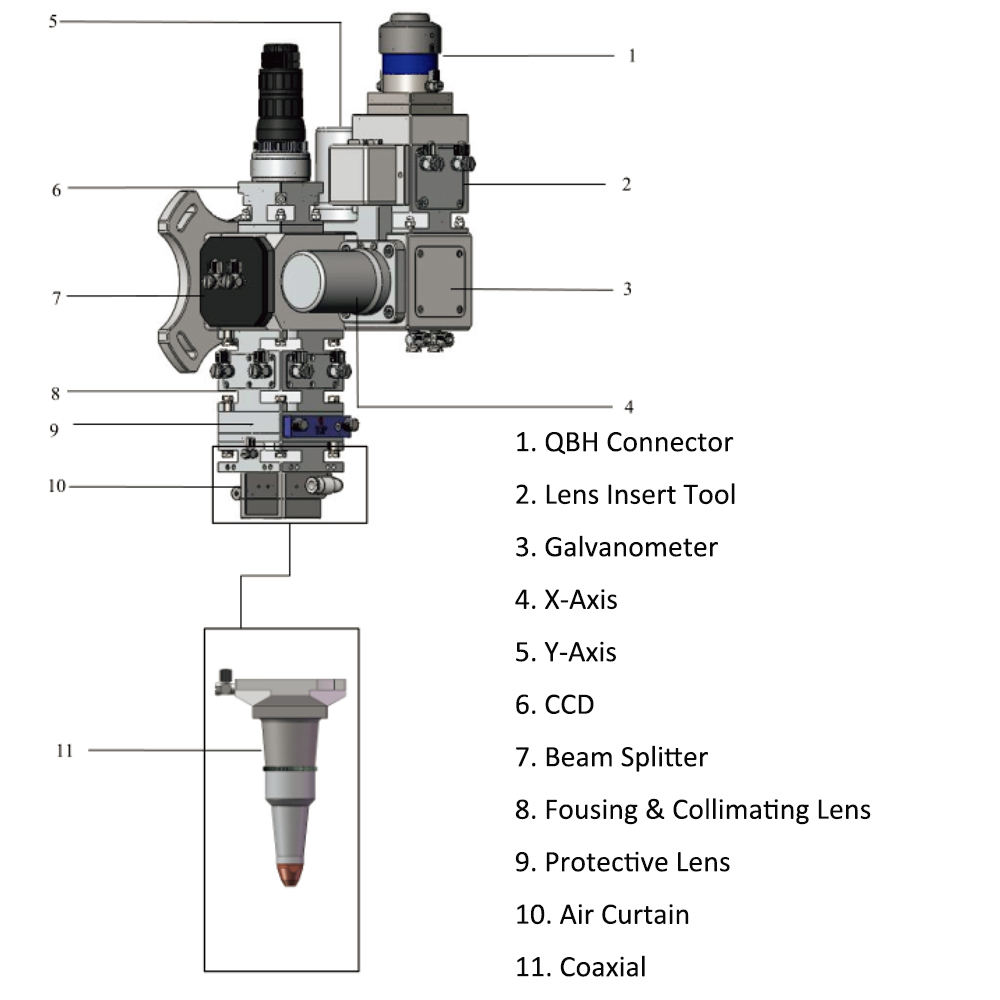

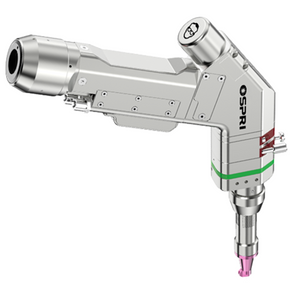

WSX ND60 6kw fiber laser wobble welding head laser welding solutions with CCD camera seam tracking system

2000W--6000W WSX Laser Transmission Wobble Welding Head ND60

Detailed information:

1.This composite fiber welding laser head is Cost-effective, having a

strong advantage in welding highly reflective materais and high

power welding.

2.It adopts the motor to drive the X, Y-axis galvanometer lens with a

variety of wobbling modes. It allows the work piece with irregular

welds, and the larger clearance. Processing parameters can

3.significantly improve the welding performance.

4.Full-sealed internal structure protects optical part from pollution by

dust.

5.Air curtain parts prevent welding slag from entering head inside.

6.Protective windows drawer: easy exchange.

7.Fit for QBH connector laser source.

Main function introduction:

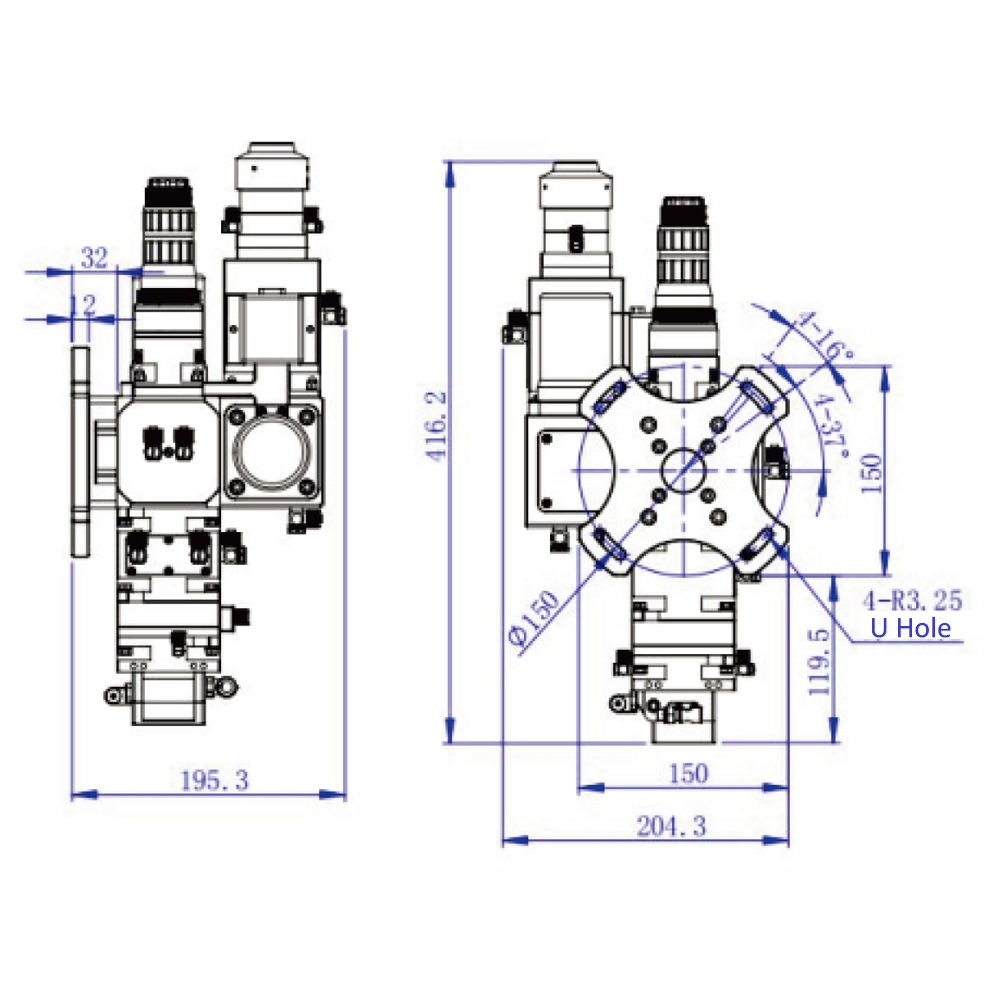

QBH components

The core connector for connecting to the laser fiber, providing an industry standard fiber access port.

Collimator Assembly

The collimating lens is assembled in the laser head, and includes a collimating lens cavity, a biconvex lens, a washer, and a locking elastic ring.

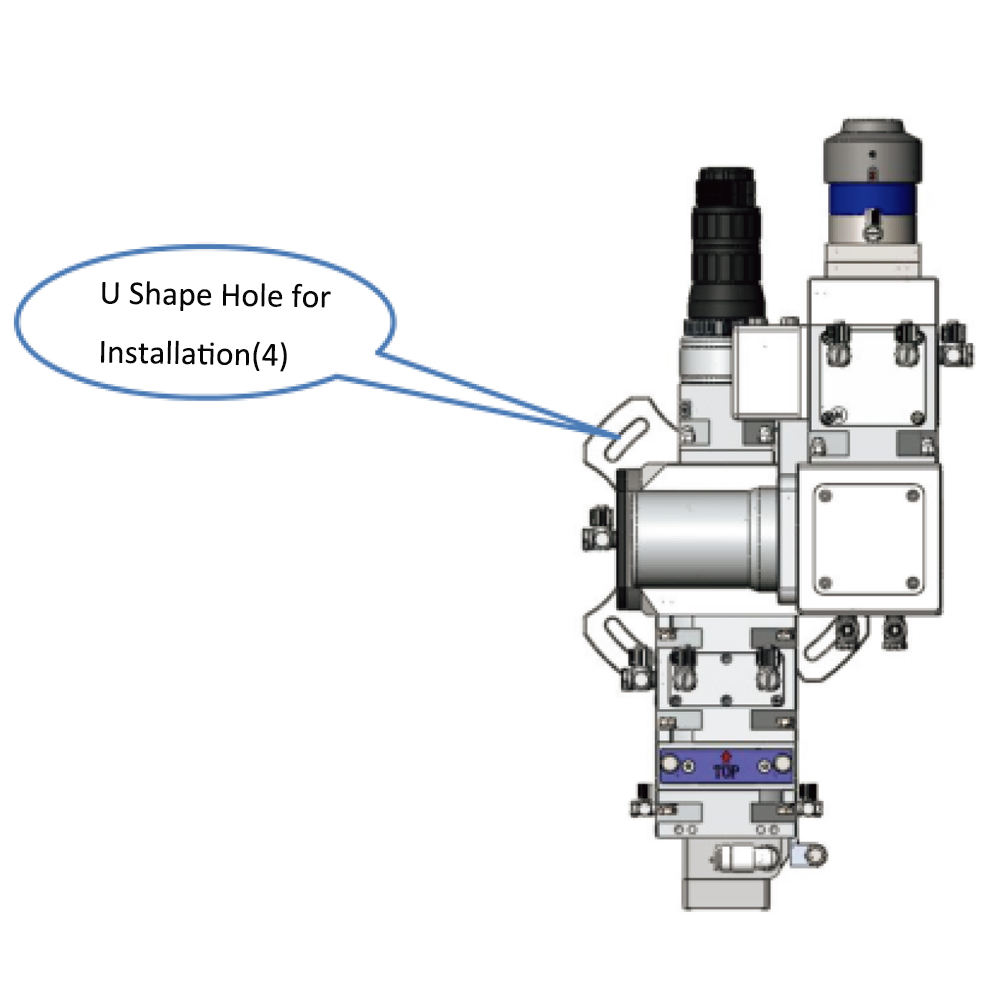

Galvo assembly

The motor drives the X and Y axis vibrating lenses, which have multiple swing modes, expand the area of the weld, and allow the workpiece to have irregular welds and larger gaps.

CCD components

Provide filtered light source to provide safe, reliable and real light source for CCD.

Focus Components

The focusing assembly is assembled in the laser head, including a focusing lens group, a focusing lens cavity, a washer, a locking spring ring and a water cooling system for lens cooling.

Protective mirror assembly

So that the welding slag can not directly splash on the focusing lens, protect and prolong the use time of the focusing lens.

Air curtain assembly

Blows away the bounced slag to protect the protective mirror.