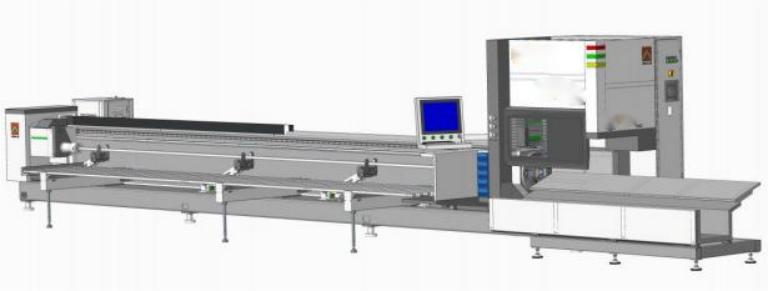

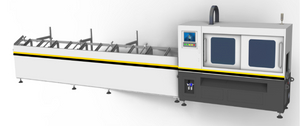

Precision Laser Tube Cutting Machine For Stainless Steel Carbon Steel

Advantageous features

1. High speed: chuck speed, cutting efficiency, standard configuration, the price of the whole machine has a high competitive advantage.

2. Material saving: 40mm ultra-short tail material, breaking the industry record, increasing the material utilisation rate.

3. High range of compatibility: Ф10~120mm pipe diameter, compatible with round pipe, square pipe, oval pipe, shaped pipe, etc., the advantage of thin-walled pipe is obvious.

4. High-precision chuck: one-time clamping, no need to replace the clamping jaws, precision long-term guarantee.

5. Automatic loading: Side-suspended machine structure, standard with semi-automatic loading machine, loading without stopping, to achieve 24 hours non-stop operation. Low cost: no high cost consumables, the main losses are electricity, protective lenses and copper nozzles ($13-15 per hour).

Key Component Configuration:

NO. | Parts name | Brand | Model/place of origin |

Key components |

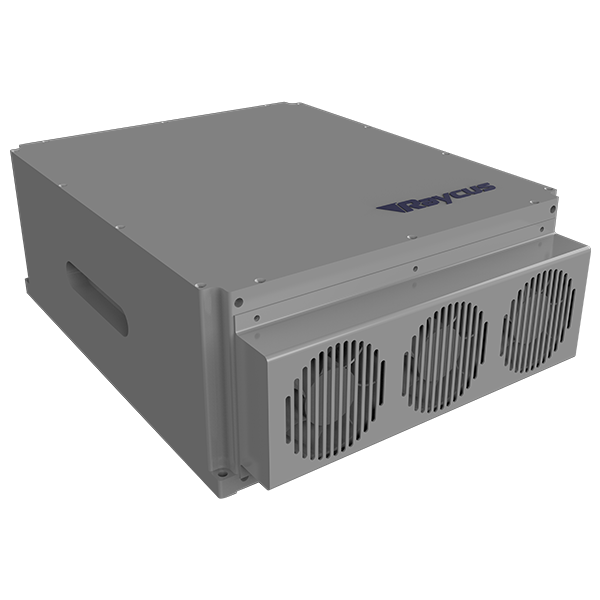

1 | Fibre Laser | RECI/MAX | 3000W/Domestic first-tier brand |

2 | Cutting Heads | OSPRI | 3000W/Domestic first-tier brand |

3 | Rack and pinion | YYC TAIWAN | M2-6 / Taiwan, China |

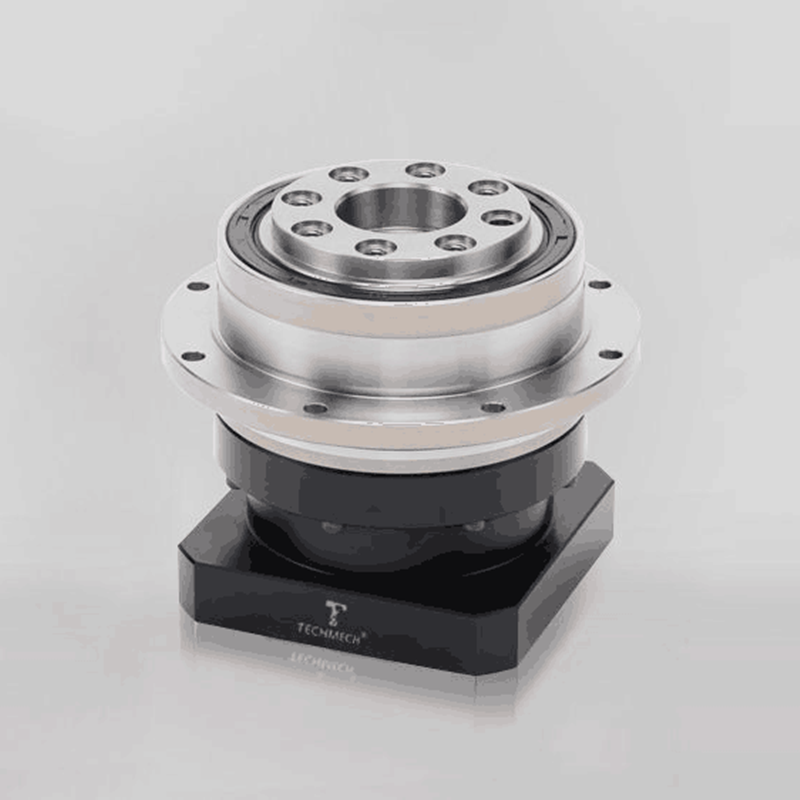

4 | Reduction gears | SHINBAO, JAPAN /MOTOREDUCER FRANCE | 090/CHINA |

5 | Linear guides | AIRTAC,TAIWAN | CGH30/CHINA |

6 | Electric motors | INOVANCE / (Yaskawa Option) | High performance motor up to 4000rpm Bus type |

7 | Dust extractor | Dust extraction fan (optional) | Domestic first-tier brand |

8 | Water cooler | HANLI | Domestic first-tier brand |

10 | Electric control components | Schneider,FRANCE | CHINA |

11 | Pneumatic components | AIRTAC,TAIWAN | CHINA |

Machined parts |

11 | Main bed | Self-developed, Suzhou | 8.5 metres/high temperature 600 degree annealing |

12 | Chuck | Self-developed, Suzhou | QL-160 Pneumatic/continuous air supply clamping |

13 | Auxiliary loading, servo-floating support bracket | In-house Research and Development, Suzhou | 4 stands/load capacity 50kg |

14 | Semi-automatic loading device | Self-developed, Suzhou | 3 conveyors for storage of 5 tubes Automatic continuous loading |

15 | Unloading device, unloading frame | Self-developed, Suzhou | 20kg per metre, up to 2.0 metres down |

Software system |

15 | Operating Systems | Shanghai bochu | Bus System/Shanghai |

16 | Nesting Software | Shanghai bochu | 3D Tube Cutting Software/Shanghai |

Other |

17 | Operating position | Left Handed Cart | Standard |

18 | Packaging and transport | Standard Packaging | Standard |

Technical parameters of components

Part Name | Causality | Parameter value |

Laser source | Output power | 3000W |

Operating Mode | Fiber-optic continuum |

Fibre diameter | 50 μm |

Cooling mode | Water chiller |

Cutting material | Carbon steel, stainless steel, aluminium alloy, copper, brass and other metals |

Machine Bed | Structure | Pipe and plate welding |

Length | 8.5 m |

Chucks | Chuck Model | QL160 |

Working Mode | 气动 |

Load capacity | 50kG |

Cutting head | Focusing distance | 125mm |

Collimation focal length | 100mm |

Focus Adjustment Speed | 100mm/s, (Manual focus not available) |

Auxiliary air pressure | ≤3Mpa |

Water chiller | Cooling medium | Distilled/deionised water |

Room temperature water/chilled water setting | 30 /20 (可调) |

Water temperature adjustment accuracy | ±0.1ºC |

Pump flow rate | 10L/Min |

Pump head | 20m |

Form | Causality | Parameter value |

Device Properties | Equipment Series | Small Platforms: 120 Series |

| Dimensions (mm) | 9600*3300*2300 |

| Total weight (tonnes) | 4.0T |

| Full power consumption (KW) | 20~25 |

| Operating temperature (℃) | 0-40 |

Scope of processing | Stroke (mm) | round tube: ¢ 10- ¢ 160 square tube: □10- □110 |

| Cutting width (mm) | 0.1-0.2 |

Range of travel | Chuck stroke (mm) | ¢ 10- ¢ 100, ¢ 70- ¢ 160 |

| Y/X/Z/U axis travel (mm) | 7000/150/250/Infinite Rotation |

Repeat Positioning Accuracy/Speed | X/Y-axis positioning accuracy (mm) | ±0.03\1000 (7000±0.06) |

| X/Y-axis repeatability (mm) | ±0.03 |

| Repeatability of rotary U-axis positioning (arcmin) | ≤5 |

| U-axis maximum rotation speed (RPM) | 130 |

Velocity and acceleration | X/Y-axis maximum acceleration | 1.3G |

| Maximum X-axis idle speed (m/min) | 100 |

| Max. Y-axis idle speed (m/min) | 130 |

Feeding parameters | Manual loading (mm) | 7000 |

| Automatic loading length (mm) | 5800~6450 (非标可 5000~7000) |

| Load cycle (s) | first feeding≤50,Subsequent loading≤18 |

| Load capacity of loading machine (kg) | 300 |

| Maximum load per tube for manual loading (kg) | 50 |

| Maximum load of single pipe for automatic loading (kg) | 50 |

Feeding parameters | Tail length (mm) | 40 |

| Maximum downstream length (mm) | Standard 2000 (customisable 4000) |

3000W Cutting speed parameters |

Material | Material thickness | Cutting speed (m/min) | Perforation time (s) | auxiliary gas |

Carbon steel | 1 | 7-10/20-25 | 0.1 | Oxygen/air |

2 | 5-7.5/13-17 | 0.1 |

3 | 3.0-3.5/5-7 | 0.1 |

4 | 3.5-4.5 | 0.2 | Oxygen |

6 | 2.4-2.6 | 0.4 |

8 | 1.6-2.3 | 0.4 |

10 | 1.4-1.7 | 0.5 |

12 | 0.9-1.2 | 0.8 |

Stainless steels | 1 | 20-25 | 0.1 | Nitrogen/Air |

2 | 12-15 | 0.2 |

3 | 7-9 | 0.3 |

4 | 3.5-4.5 | 0.4 |

6 | 1.3-1.8 | 0.6 |

8 | 0.8-1 | 0.8 |

Aluminium | 1 | 20-25 | 0.1 | Nitrogen/Air |

2 | 13-17 | 0.1 |

3 | 6-8 | 0.2 |

4 | 3.5-4.5 | 0.4 |

5 | 2-3 | 0.4 |

6 | 1.3-1.8 | 0.6 |

Brass | 1 | 22-26 | 0 | Nitrogen |

2 | 10-15 | 0.4 |

3 | 6-8 | 0.5 |

4 | 2.5-3.5 | 0.8 |

6 | 1-1.5 | 0.8 |

Copper (pure copper, as opposed alloy) | 1 | 20-25 | 0 | Oxygen |

2 | 9-12 | 0.1 |

3 | 3.5-5.5 | 0.3 |

4 | 2.2-2.5 | 0.4 |

Remarks: (The degree of gas purity, pipe quality, etc. will affect the cutting speed and quality, the speed is for reference only)

Test conditions: nitrogen pressure ≥ 2.0MPA; air pressure ≥ 1.5MPA; air flow ≥ 2.5m³/min; oxygen pressure ≥ 1.0MPA

Protective gas requirements | Relevant data | Remarks requirements |

Oxygen | Purity: ≥99.6 per cent Gas with a purity lower than ≥99.6% will have an impact on the cutting effect and quality. | Carbon steel and all kinds of iron plate cutting Oxygen-assisted cutting, cutting quality and high efficiency. |

Pressure: 1MPa Flow rate ≥1m³/min |

Nitrogen | Purity: ≥99.99 per cent Gases with purity lower than ≥99.99% will have an effect on cutting effect and quality. | Cutting of stainless steel, galvanised sheet, etc. Nitrogen-assisted cutting, good cutting quality. |

Pressure: 2.5MPa Flow rate ≥2.5m³/min |

1、Bottled gas should be equipped with cylinder pressure reducing valve. 2、Oxygen (O2) pressure reducing valve: outlet pressure adjustable range: 0.4Mpa-1.2MPa pressure fluctuation range of 1%. 3、Nitrogen (N2) pressure reducing valve: outlet pressure adjustable range: 0.4Mpa-5MPa pressure fluctuation range of 1%. |

Atmosphere | Working pressure ≥1.3MPa | 1, if you need to use air cutting, the user should provide their own air compressor, dryer, storage tanks, and four-stage filtration (filtration accuracy of 0.01 microns) 2. The gas from the air to the laser cutting machine should not have water and oil or affect the quality of cutting and the life of various lenses. 3、Dew point temperature should not be higher than 5 degree Celsius. 4、Oil content ≤ 0.003ppm Solid particles ≤ 0.01 micron. |

Flow rate ≥1.8m³/min |

installation environment | Relevant data | Remarks requirements |

temperature requirement | 5~30° | Simple lasers are recommended to be placed in a separate air-conditioned and isolated room. |

Humidity requirements | <70% |

|

Foundation requirements | Level site No strong vibration | 1、If there is a strong vibration, you need to open the anti-vibration trench. 2、Strength of the foundation should be ensured, and there should be no settlement. 3、According to the footing installation diagram provided by our company to do a good job of footing |

Remarks: The equipment placement site must be well ventilated, free of dust, corrosion and water leakage. Control Cabinet, laser is the core of the equipment, should avoid the equipment to suffer from such as arc welding and electrical discharge processing machine and other equipment should be avoided from electromagnetic wave interference, such as arc welding and electric discharge machine, so as not to affect the normal operation of the equipment. |