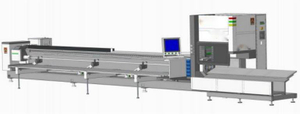

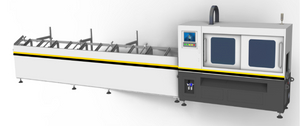

CW Laser Clean Machine for Metal Rust

Laser cleaning Machine is a new generation of industrial surface cleaning laser system. It adopts the advanced laser source, laser optical scanners and control system to meet the requirements of metal surface cleaning process.

Our Laser cleaning machine can be used car perimeter, rubber mold, heritage restoration, ship, environmental protection industry, others, rail transit, high-end machine tools Remove coating, degumming, lithographic surface treatment, oil removal, pretreatment, paint removal, rust removal,etc.

1 in the solid surface to produce a mechanical resonance phenomenon, is the surface of the dirt layer or condensation debris;

2 the surface dirt layer is heated and expanded, so as to overcome the adsorption force of the basic material to the dirt

particles and the surface of the object is separated from the surface of the object;

3 instant to make the dirt molecules evaporate, gasification or decomposition

1. Cleaning of edges and corners can be realized: the optical device makes the laser beam move back and forth quickly on the workpiece. Different scan patterns and speeds are available depending on the desired cleaning effect. A linear scanning motion can be used to clean micro-contamination; if a deeper cleaning is required, use overlapping scanning or increase the power of the device.

2. Precise positioning cleaning: the laser can clean its surface, such as aluminum, carbon fiber composite material or coated parts, without damaging the underlying material. Alternatively, by choosing a different parameter set, the same laser can also roughen the surface, increasing the strength of the bond. The flexibility of laser tools allows them to be applied to the wide variety of tasks required, and laser cleaning costs approximately five times less than comparable wet chemical cleaning processes.

3. Green cleaning option: "Clean" not only means that the effect of laser cleaning is very clean, but also the cleaning process itself is a green process. Unlike wet chemical processes, it does not use toxic solvents. Moreover, the noise and damage to the substrate caused by the abrasive method are avoided.