RFL-C1500 Fiber Laser Source

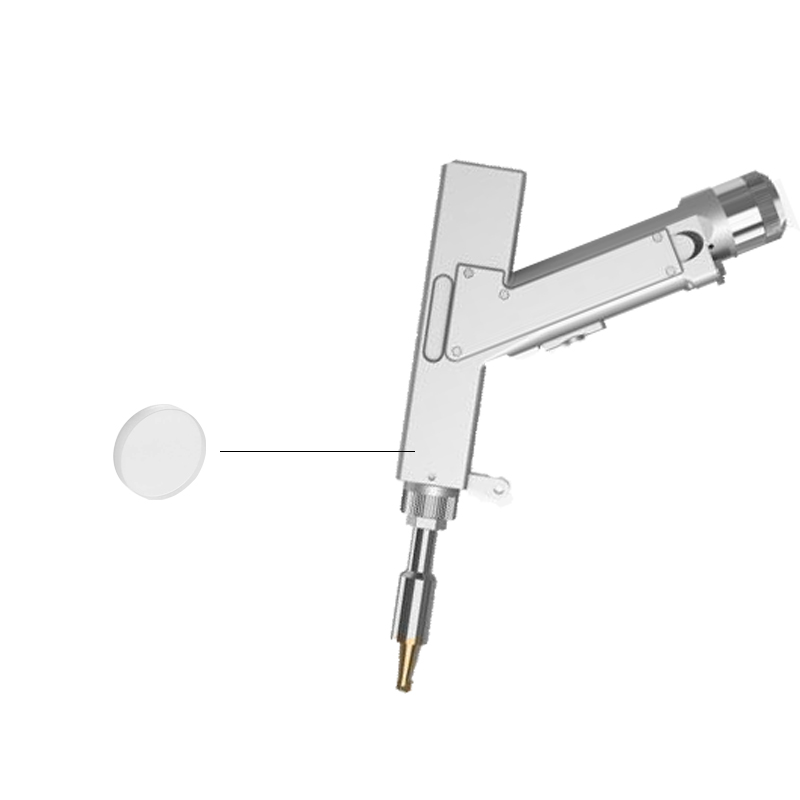

The RFL-C1500 is a high-performance fiber laser with advanced capabilities designed for a wide range of industrial applications. It features excellent electro-optical conversion efficiency, superior and stable beam quality, and enhanced anti-reflection capabilities, making it ideal for cutting, welding, drilling, and more. This laser system is particularly suited for precision tasks, delivering narrow cuts with bright, smooth surfaces. Compared to other lasers in the market, it offers distinct advantages in performance, reliability, and operational efficiency.

Key Features:

High Electro-Optical Conversion Efficiency: Ensures better energy savings and lower operating costs.

Stable Beam Quality: Delivers precise cutting and welding results, particularly on thick materials.

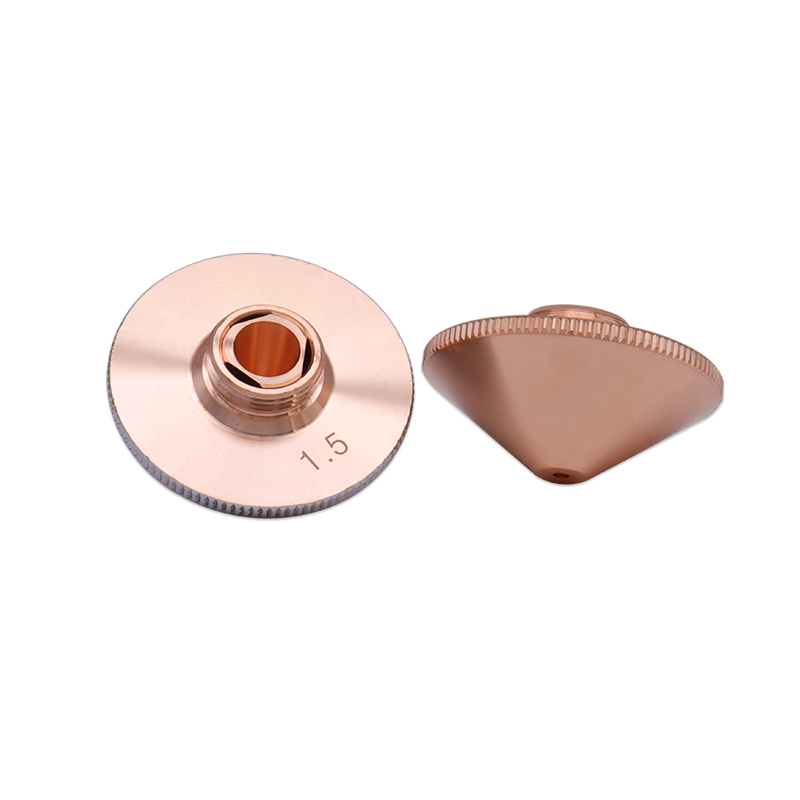

Anti-Reflection Technology: Optimized for working with highly reflective metals such as aluminum and copper, reducing the risk of damage.

Second-Generation Fiber Transmission System: Guarantees stable and precise cutting performance, especially for thick plates.

Versatile Applications: Suitable for cutting, welding, drilling, medical device processing, and more.

Optical Characteristics:

Average Output Power: 1500W

Central Wavelength: 1080 ± 5 nm

Modulation Frequency: 50 to 20,000 Hz

Power Stability: ±1.5%

Red Light Indicator Power: 0.1 to 1 mW

Output Characteristics:

Connector Type: QBH (customizable)

Beam Quality (M²): 5-6 (with a 50μm fiber core diameter)

Polarization State: Random

Fiber Length: 20 meters (customizable)

Electrical Control Characteristics:

Input Power: 220 VAC ± 10%, 50/60 Hz

Control Modes: External RS232, External AD, Ethernet

Power Adjustment Range: 10% - 100%

Other Specifications:

Dimensions (W x H x D): 410 x 610 x 150 mm (including handles)

Weight: Less than 40 kg

Cooling Method: Water cooling

Operating Temperature: 10°C - 40°C

Operating Humidity Range: Less than 70%

Applications:

Precision Cutting: Suitable for fine cutting operations, particularly for metal sheets and components.

Metal Welding: Ideal for precision welding tasks in various industries, including automotive and aerospace.

Thin Plate Drilling: Delivers precise, clean drill holes in metal surfaces.

Metal Marking and Surface Treatment: Suitable for engraving, marking, and surface processing applications.

3D Printing and Rapid Prototyping: Used for additive manufacturing and rapid prototyping with metals.