Laser Protective Lenses

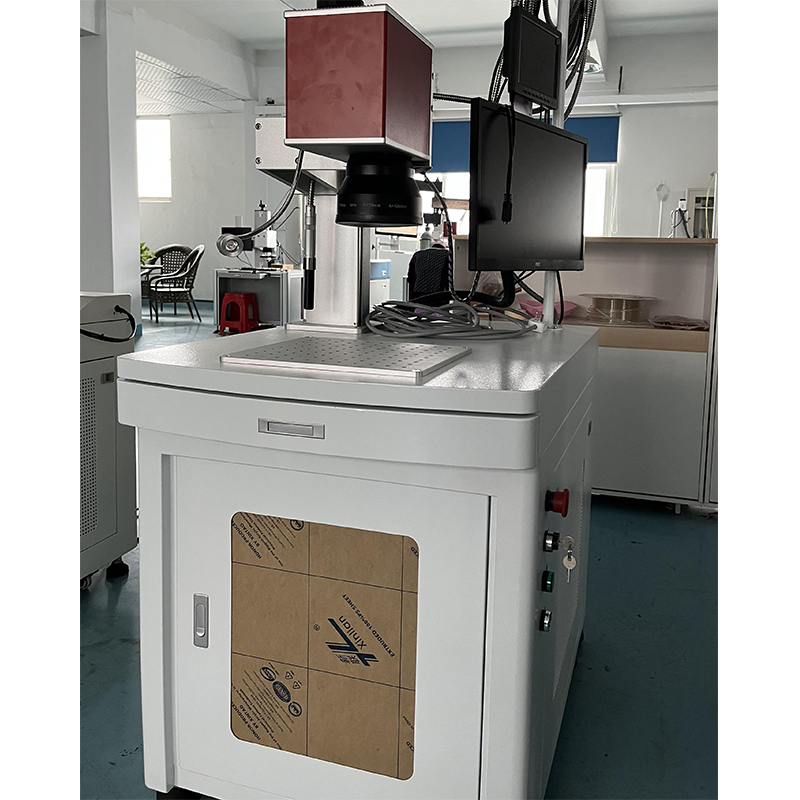

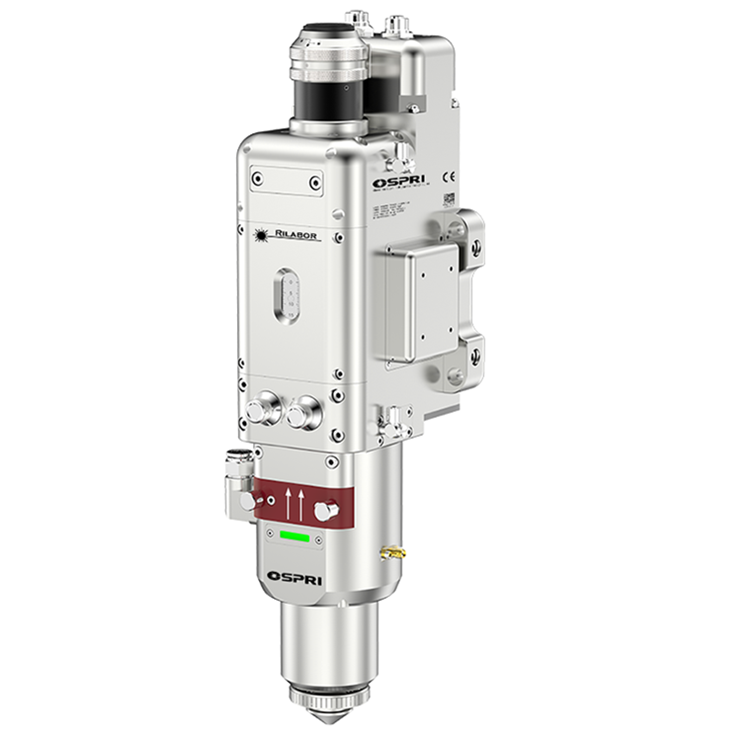

Laser protective lenses are essential components used in laser cutting and welding applications. They serve to protect the operator's eyes from harmful laser radiation and to ensure optimal performance of the laser equipment.

Key Features:

Material: Typically made from high-quality quartz or specialized glass, these lenses provide excellent transmission of laser light while filtering out harmful wavelengths.

Coating: Many lenses are coated to enhance durability, reduce reflection, and improve optical clarity. Coatings can also help to minimize the buildup of contaminants.

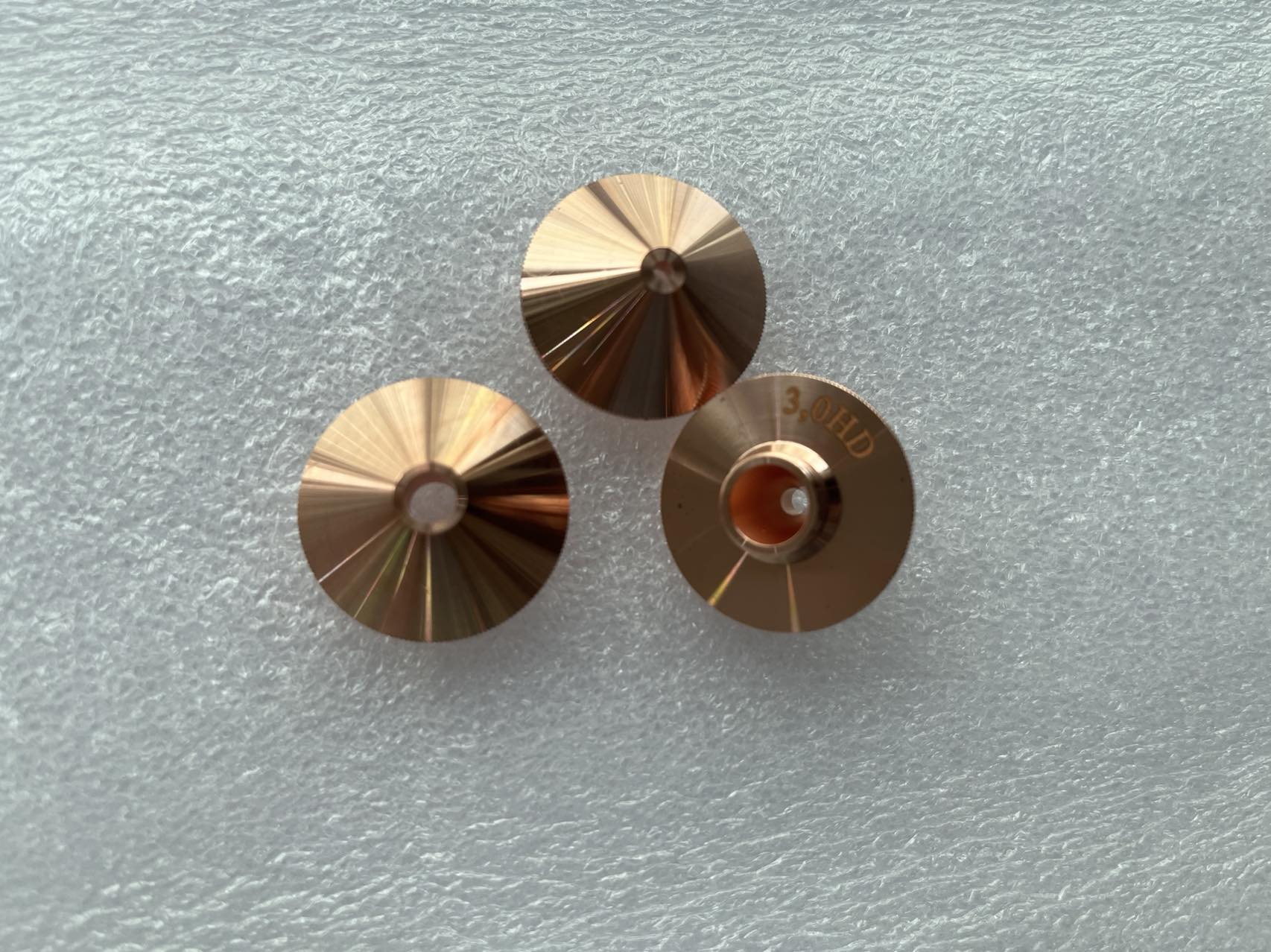

Sizes and Shapes: Laser protective lenses come in various sizes and shapes to fit different laser systems and applications. Common diameters include options like 18mm, 22mm, and 50mm, among others.

Applications: These lenses are used in various laser systems, including fiber lasers, CO2 lasers, and solid-state lasers, for tasks such as cutting, welding, and engraving metals and other materials.

Safety Standards: Laser protective lenses must meet specific safety standards to ensure they effectively protect against laser radiation and comply with regulations.

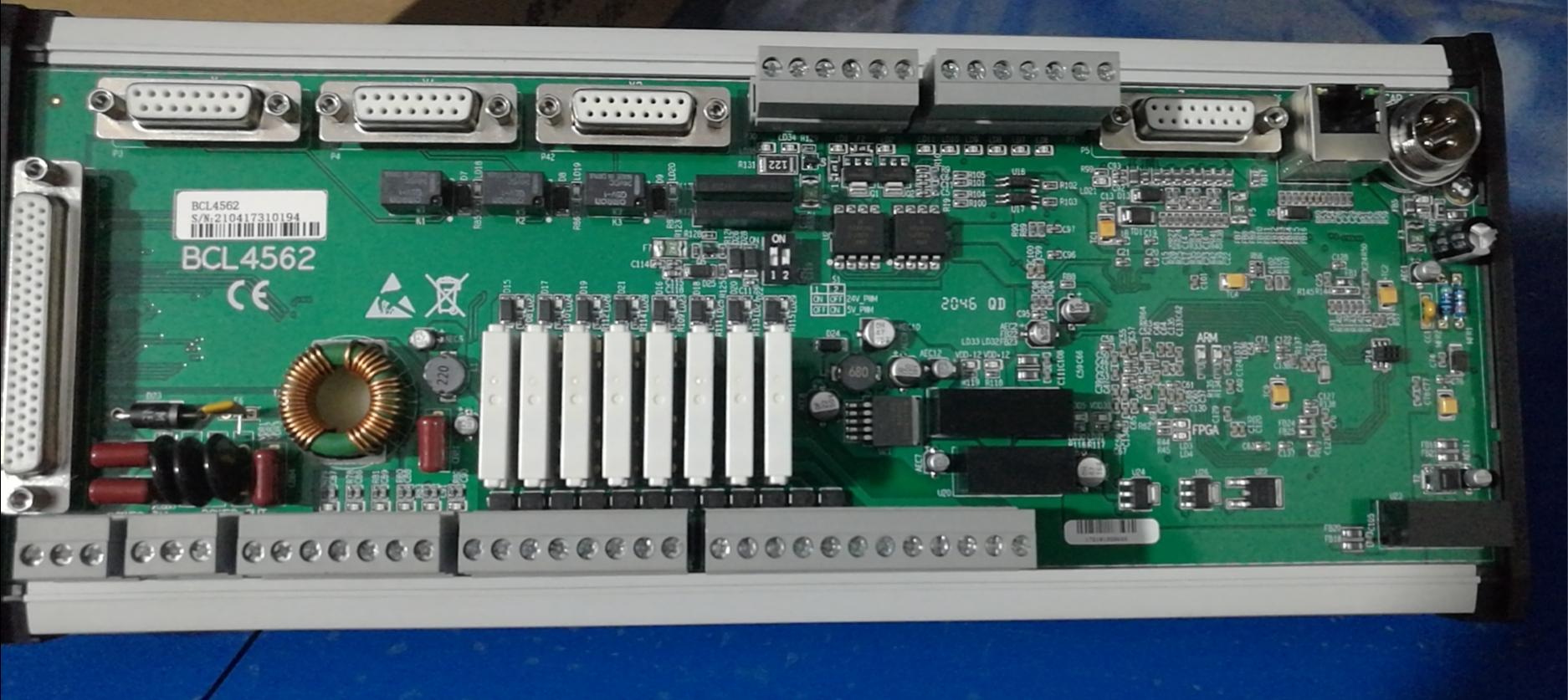

Imported Quartz Coated Fiber Cutting Machine Welding Head Accessories

Importance:

Using high-quality laser protective lenses is crucial for maintaining safety in the workplace, preventing eye injuries, and ensuring the efficiency and effectiveness of laser operations. Proper care and maintenance of these lenses can extend their lifespan and enhance overall equipment performance.