Laser cutting nozzles play a critical role in laser cutting systems, helping to direct the assist gas and focus the laser beam onto the material being cut. Different nozzles are used for specific materials and applications, and they can significantly impact cutting quality, speed, and precision.

Types of Laser Cutting Nozzles:

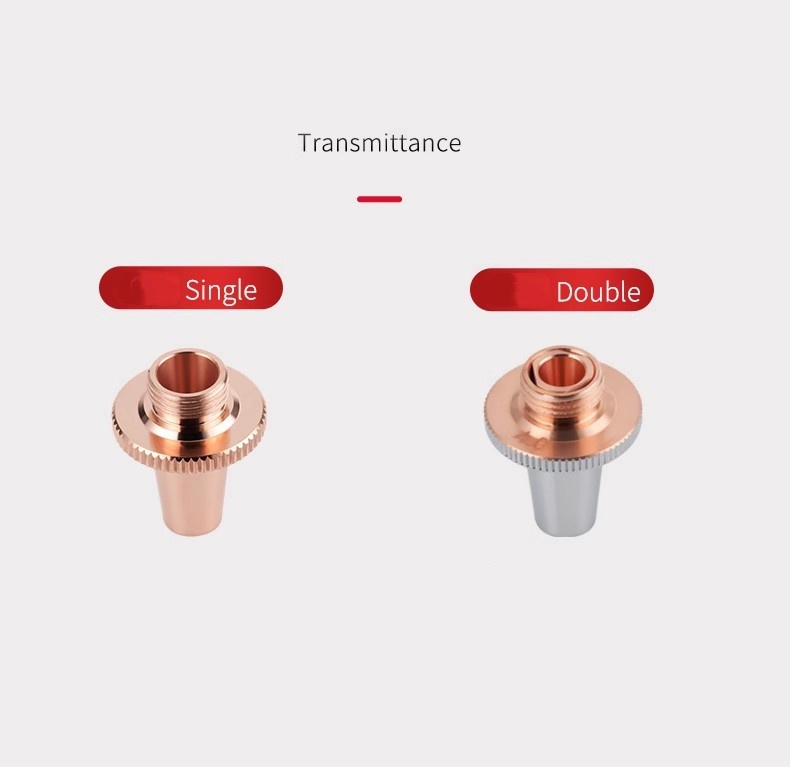

Single-Layer Nozzles:

Typically used for lower-pressure gas cutting applications, such as cutting stainless steel or aluminum.

Have a single outlet for gas flow.

Provides precision in directing the laser beam and gas to cut thin to medium-thickness materials.

Double-Layer Nozzles:

Designed for higher-pressure cutting, commonly used for cutting thicker materials like carbon steel.

The dual layer helps optimize the gas flow, creating a more focused and efficient cutting process.

Better suited for high-speed cutting and thick metal.

Common Parameters for Nozzles:

Diameter (D): The size of the nozzle opening, which affects the focus of the gas flow and laser beam.

Thread Size (M): The size of the threaded part, which allows the nozzle to fit into the laser cutting head.

Height (H): The total height of the nozzle, important for maintaining the correct distance from the workpiece.

Hole Size (φ): The size of the central hole, influencing the concentration of gas and laser.

Key Nozzle Features:

Material: Brass is commonly used because of its durability and resistance to heat.

Size: Smaller diameter nozzles (e.g., 1.0mm, 1.5mm) are used for cutting thin materials, while larger diameters (e.g., 3.0mm, 4.0mm) are for thicker materials.

Gas Compatibility: Nozzles are designed to work with different gases (oxygen, nitrogen, or air) depending on the material and the cutting process.

Applications:

Stainless Steel Cutting: Double-layer nozzles with nitrogen gas are typically used for high-quality stainless steel cuts.

Carbon Steel Cutting: Single-layer or double-layer nozzles with oxygen gas are used for cutting carbon steel at high speeds.

Aluminum & Non-Ferrous Materials: Requires nozzles that can handle the unique properties of these metals, typically using nitrogen as the assist gas.

Selecting the Right Nozzle:

Material Thickness: Thinner materials often use smaller diameter nozzles, while thicker materials require larger nozzles.

Gas Pressure: Double-layer nozzles are often preferred for high-pressure applications to ensure efficient cutting.

Cutting Speed: Different nozzles provide varied cutting speeds, and the nozzle type must match the machine settings for optimal results.

Specified laser cutting nozzles:

| Type | Diameter (D) | Thread (M) | Height (H) | Size (φ) | Part Number |

| Single | 15mm | M8 | 19mm | 1.0mm | 120GJT0910 |

| Single | 15mm | M8 | 19mm | 1.2mm | 120GJT0912 |

| Single | 15mm | M8 | 19mm | 1.5mm | 120GJT0915 |

| Single | 15mm | M8 | 19mm | 2.0mm | 120GJT0920 |

| Single | 15mm | M8 | 19mm | 2.5mm | 120GJT0925 |

| Single | 15mm | M8 | 19mm | 3.0mm | 120GJT0930 |

| Single | 15mm | M8 | 19mm | 3.5mm | 120GJT0935 |

| Single | 15mm | M8 | 19mm | 4.0mm | 120GJT0940 |

| Double | 15mm | M8 | 19mm | 0.8mm | 120GJT0208 |

| Double | 15mm | M8 | 19mm | 1.0mm | 120GJT0210 |

| Double | 15mm | M8 | 19mm | 1.2mm | 120GJT0212 |

| Double | 15mm | M8 | 19mm | 1.5mm | 120GJT0215 |

| Double | 15mm | M8 | 19mm | 2.0mm | 120GJT0220 |

| Double | 15mm | M8 | 19mm | 2.5mm | 120GJT0225 |

| Double | 15mm | M8 | 19mm | 3.0mm | 120GJT0230 |

| Double | 15mm | M8 | 19mm | 4.0mm | 120GJT0240 |

| Single | 11.5mm | M6 | 16mm | 0.8mm | 211GJT0900 |

| Single | 11.5mm | M6 | 16mm | 1.0mm | 211GJT0901 |

| Single | 11.5mm | M6 | 16mm | 1.2mm | 211GJT0902 |

| Single | 11.5mm | M6 | 16mm | 1.5mm | 211GJT0903 |

| Single | 11.5mm | M6 | 16mm | 1.8mm | 211GJT0904 |

| Single | 11.5mm | M6 | 16mm | 2.0mm | 211GJT0905 |

| Single | 11.5mm | M6 | 16mm | 2.5mm | 211GJT0906 |

| Single | 11.5mm | M6 | 16mm | 3.0mm | 211GJT0907 |

| Single | 10.8mm | M10 | 16mm | 1.0mm | 120GJT0310 |

| Single | 10.8mm | M10 | 16mm | 1.5mm | 120GJT0315 |

| Single | 10.1mm | M5 | 12mm | 2.0mm | 210GJT0173 |

| Single | 10.1mm | M5 | 12mm | 1.2mm | 210GJT0227 |

| Single | 10.1mm | M5 | 12mm | 3.0mm | 210GJT0907 |

| Single | 10.2mm | M6 | 16mm | 1.5mm | 211GJT0172 |

| Single | 15mm | M10 | 16mm | 1.5mm-TRA0369 | 211GJT0682 |

| Single | 15mm | M10 | 16mm | ¢2-TRA0369 | 211GJT0683 |

| Single | - | M11 | 18mm | 2.0mm | 120GJT1120 |

| Single | - | M11 | 18mm | 5.0mm | 120GJT1150 |

| Double | - | M11 | 18mm | 1.2mm | 120GJT1412 |