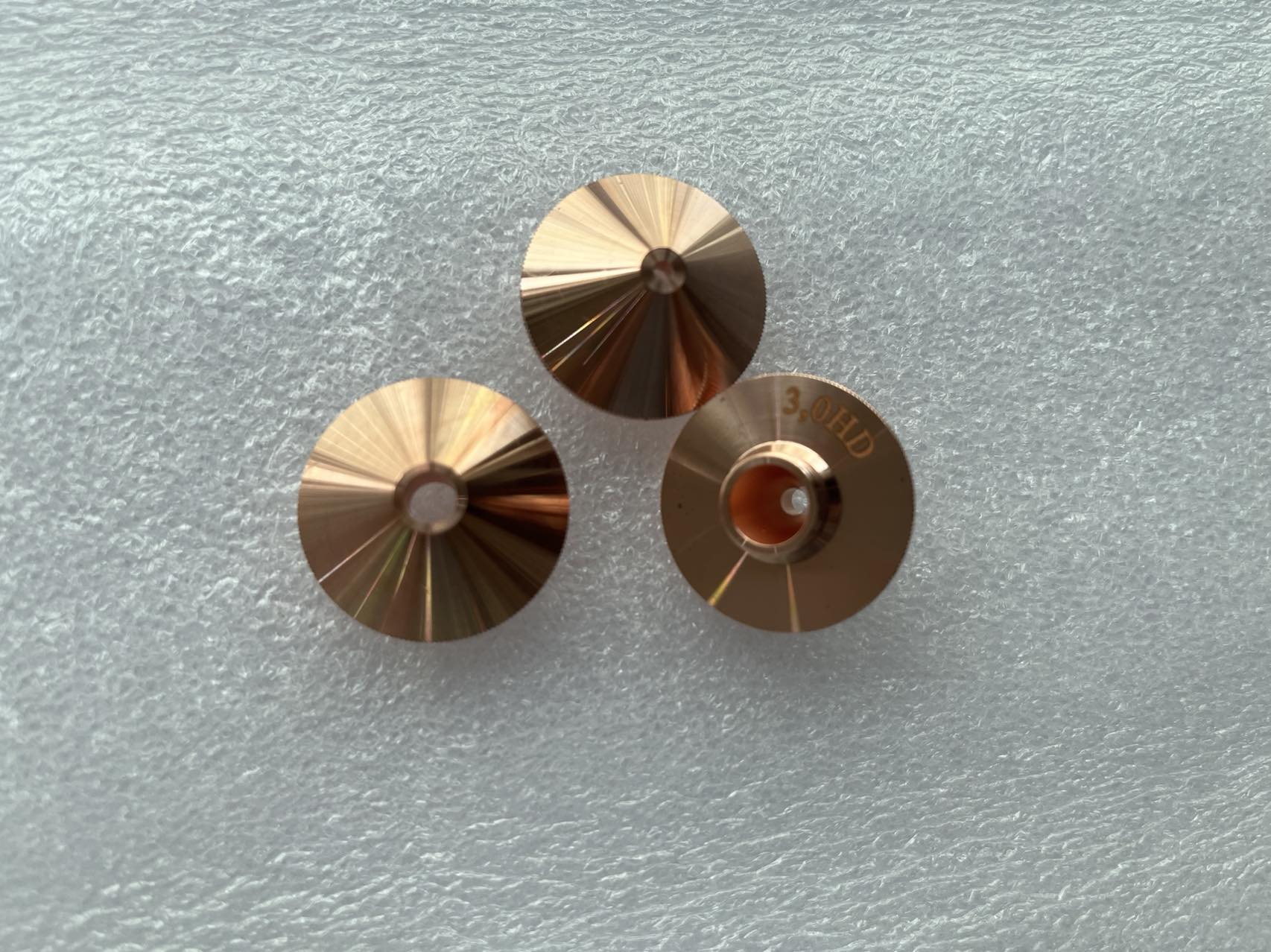

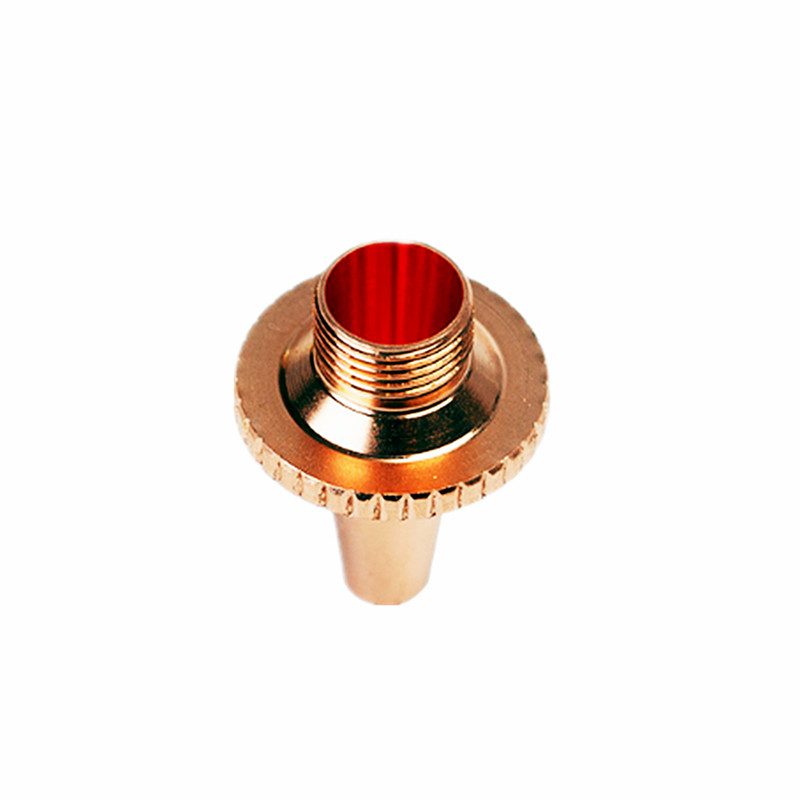

3D Single Layer for Raytools Fiber Laser Cutting Head Parts Laser nozzles 3D M6 Single Layer

Nozzle and nozzle height

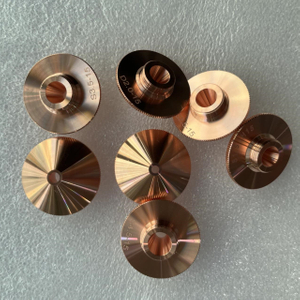

As a beam and auxiliary gas channel, the shape, aperture and height of the nozzle will affect the cutting effect.

The nozzle mainly controls the area and size of gas diffusion, thus controlling the cutting quality; Prevent the fragments from springing up like slag and contaminating the lens through the nozzle. Generally speaking, when cutting thin plates, the defocus amount is small, and small diameter nozzles are used; When cutting thick plates, use large diameter nozzles.

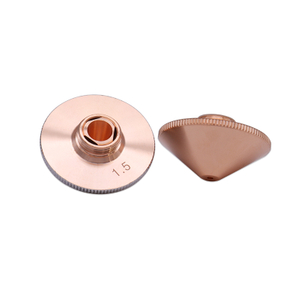

The nozzle is divided into single layer and double layer. Single-layer laser nozzle is used for melting and cutting, that is, nitrogen is used as auxiliary gas to cut stainless steel, aluminum plate, etc; Cut carbon steel.

The nozzle height is the distance between the nozzle outlet and the workpiece surface. When cutting, we usually set this height to 0.3mm-0.8mm. If it is too low, the nozzle can easily collide with the workpiece surface. If it is too high, the concentration and pressure of auxiliary gas will be reduced, and the cutting quality will be reduced. When piercing, the height of the nozzle can be increased appropriately to prevent the slag from reflecting onto the lens.

3D Laser Cutting Nozzles:

-

Dry-running and corrosion-resistant

Resistant to dust and dirt♧Extremely durable

Quiet running♧Compensates misalignment and deflections

Easy installation

Longer life

The surface has undergone anti-oxidation treatments such as chrome plating, and the nozzle has a longer storage time and is more durable.

Features:

1. Single layer nozzles use Nitrogen gas and Air as auxiliary gases to cut stainless steel sheets, aluminum sheets and copper sheets etc.

2. Double layer nozzles use oxygen gas as auxiliary gases to cut metal sheets like carbon steel.

3. High quality nozzle is very important to the cutting quality.

4. The nozzle is made of quality copper material to ensure not the stable signal transmission, but also the fast heat dissipation to prolong service life. The production process of the nozzles is strictly in accordance with manufacturing technique. The surface is bright and clean, by special passivation treatment, to reduce fly flag adhesion and cutting craters .

Nozzle is an important part that affects the quality and efficiency of laser cutting. Laser cutting generally uses coaxial (air flow and optical axis are concentric) nozzles, and the nozzle outlet diameter should be selected according to the thickness of the plate. In addition, the distance between the nozzle and the workpiece surface also has a great impact on the cutting quality. In order to ensure the stability of the cutting process, this distance must be kept constant.

Nozzle is one of the most important parts in laser cutting. It is located at the bottom of the laser head, and the laser beam and auxiliary gas are emitted through the nozzle. Its main function is to gather the auxiliary gas and form high pressure, release it to the surface of the cutting material and the slit, blow away the melted and vaporized base metal produced in the cutting process, leaving a clean slit; At the same time, prevent slag, smoke and other pollutants from rebounding upward, thus protecting the internal lens.

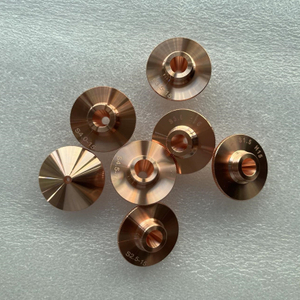

The concentricity of the nozzle center and the laser beam is one of the important factors affecting the cutting quality. Therefore, the nozzle must be coaxial with the laser beam to obtain a better cutting surface.

Influence on cutting quality when the nozzle center is different from the laser beam center

(1) The cutting gas is sprayed from the nozzle center and acts on the plate surface and weld. If the laser is not in the nozzle center, the laser action position will deviate from the direction of the air flow, and the section effect in different directions will be inconsistent.

(2) If the laser is not in the center of the nozzle, it may hit the inner wall of the nozzle, affect the cutting effect and seriously burn the nozzle directly.

Adjustment method for coaxiality of nozzle and laser beam:

1) Apply transparent adhesive tape on the nozzle mouth, and the adhesive tape will leave a circular mark on the nozzle mouth.

2) With a power of about 300W, the laser will penetrate the tape and leave a small hole.

3) Remove the transparent tape and observe the relative position of the hole and the circle.

If the small hole is in the center of the circle, it indicates that the laser is coaxial with the nozzle; If the small hole does not coincide with the center of the circle (different axis), or the small hole cannot be seen (the laser beam may hit on the inner wall of the nozzle), it is necessary to adjust the adjusting screw on the laser cutting head, and then conduct spot shooting comparison until the laser output center coincides with the center of the nozzle.

Nozzle type selection

Generally, laser cutting nozzles are divided into single-layer nozzle and double-layer nozzle. Single-layer nozzle is usually used for cutting stainless steel, aluminum alloy, copper alloy, etc., and nitrogen is generally used as auxiliary gas. Because of its high gas flow rate, the double-layer nozzle is generally used for high-speed cutting and oxygen cutting of carbon steel, but its cutting surface will be blackened due to oxidation.

Nozzle size selection

The size of nozzle diameter determines the flow rate of gas entering the base metal and slit, thus affecting the removal of molten material. The larger and faster the gas flow into the incision, the stronger the ability of jet to remove molten material.

Theoretically, the thicker the plate, the larger the nozzle should be used. However, the larger the aperture of the nozzle, the greater the probability that the sparks of the molten material will splash and bounce upward during cutting, and the shorter the service life of the lens.

When the nozzle is deformed or there are molten stains on the nozzle, the cutting effect will be affected. Therefore, the nozzle should be placed carefully to avoid being bruised or deformed. If there is molten stain on the nozzle, it should be cleaned in time.