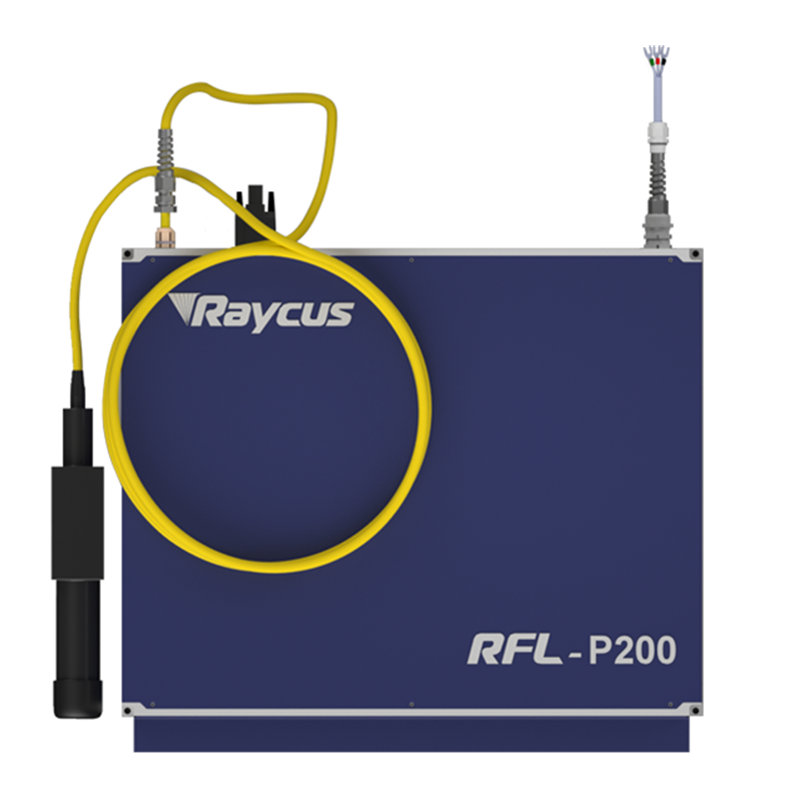

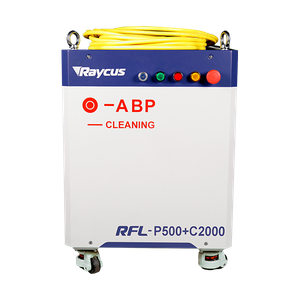

Raycus Adjustable Beam Profile High Power Fiber Lasers for Lithium battery industry welding

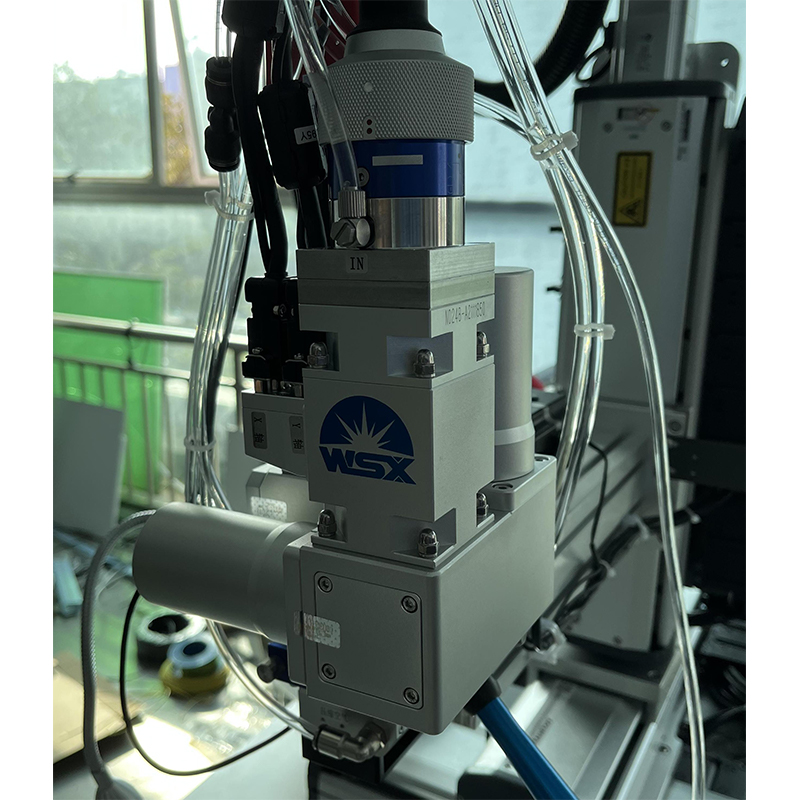

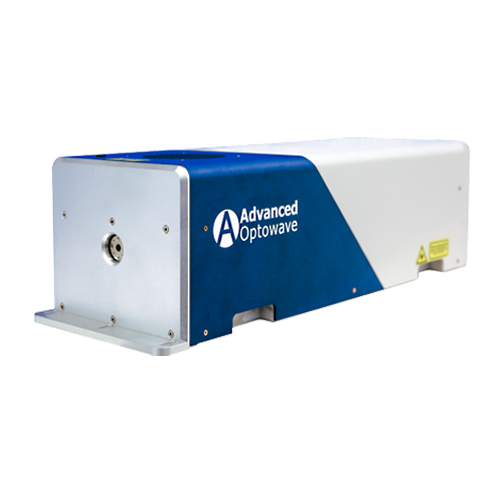

Raycus new generation ABP(adjustable beam profile) Fiber Laser is idael choice for welding . With the latest beam adjustable technology, the application of welding becomes different. The use of customized fiber combiner developed by Raycus enables the output of different modes such as Gaussian beam, ring beam and the mix of the two. Different modes can be freely switched depending on processing requirements.Meanwhile, the power of the central beam and the ring beam are adjust-ed independently to achieve any power ration of central beam/ring

beam. The optical module is independently and respectively coupled into the central core and the ring core of the output fiber cable. The power of the central beam and the ring beam are adjusted independent-ly; the switch of power can be done within a matter of milliseconds. The APB lasers can meet the demand of high-quality laser cutting and welding, and become another type of good tool to improve the process-ing quality and efficiency.

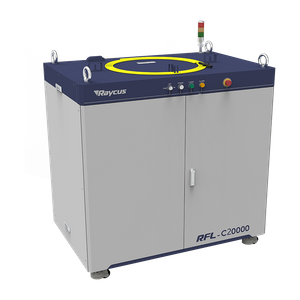

Product Specifications:

Applications:

Lithium battery industry

Electronic Component

Car manufacturing

Application Industry:

1. Adjusted independently power of center spot and ring spot

2. Spatter-free welding

3. Stable weld formation and good consistency

4. Larger and stable molten, smaller temperature gradient

Raycus showed various laser solutions for power battery manufacturing applications, including power battery pole cutting, explosion-proof valve, peripheral sealing, soft joint welding, surface marking, hard hat, battery level with fine processing etc. , as well as other innovative products, live demonstrations and some delicate samples.

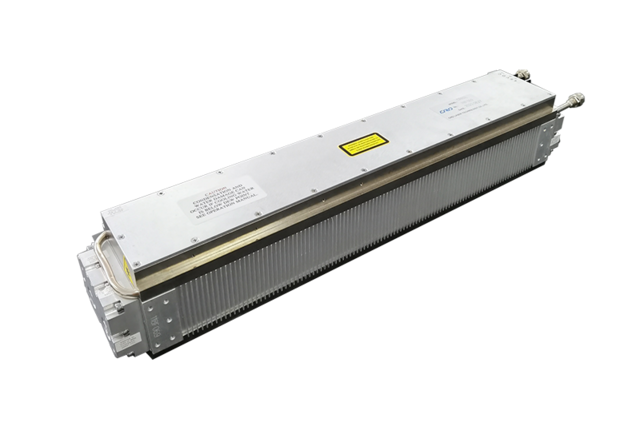

1000W-2000W Welding Solution

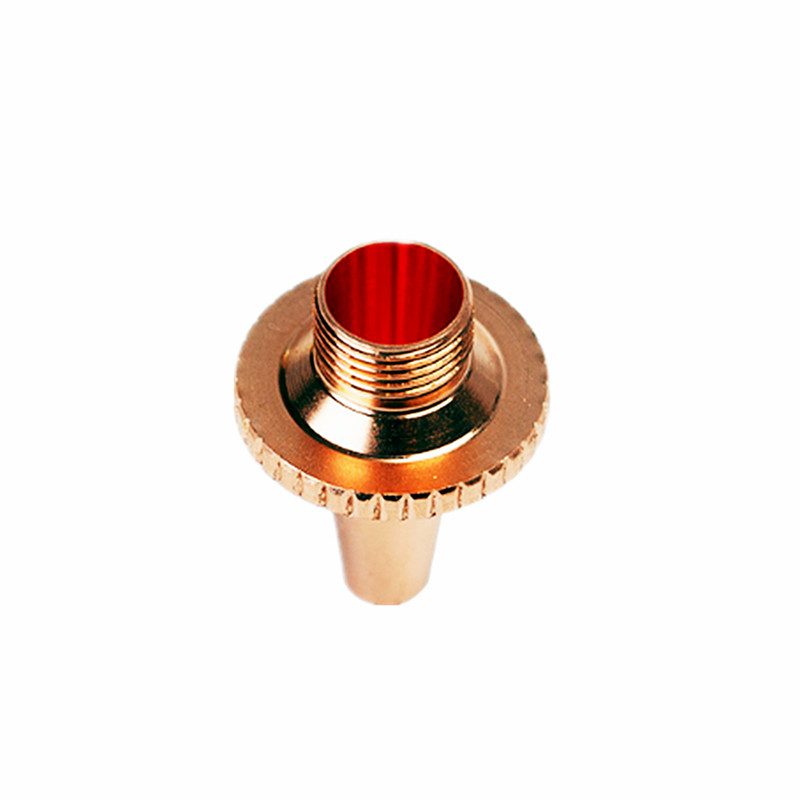

The material thickness of explosion-proof valves, tabs, helmets, housing seals, electrode posts and other components is generally small, usually between 0.2 and 2 mm. These components are mainly required for sealing or not required for weld strength. The laser power for soldering such components is generally relatively small, and the three lasers of 1000W, 1500W, and 2000W can basically meet the requirements.

It can be widely used in complicated and irregular welding processes in cabinets, kitchens and bathrooms, staircase elevators, shelves, ovens, stainless steel door and window guardrails, power distribution boxes, stainless steel household appliances and other industries. It can applied to stainless steel, iron sheet, aluminum, copper, alloy, steel, galvanized,etc.