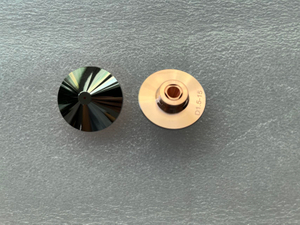

Nozzle is an essential component of laser cutting head: It is through the cutting nozzle that the laser beam and cutting gas meet the workpiece. Selecting the right nozzle is therefore crucial for part quality. Ensure you have the best cutting quality。

Regarding single-layer and double-layer nozzle selection:

single-layer nozzles are often used for melting cutting, that is, cutting stainless steel and aluminum plates with nitrogen as auxiliary gas; double-layer nozzles are generally used for oxidizing cutting, that is, carbon steel cutting with oxygen as auxiliary gas.

Regarding laser cutting nozzle sizes (mm):

0.8, 1.0, 1.2, 1.5, 2.0, 2.5, 3.0, 3.5, 4.0, 4.5, 5.0, etc., while the usual nozzle sizes are: 1.0, 1.2, 1.5, 2.0, 2.5, 3.0. In recent years, the wide application of 10kw high-power lasers has appeared: 1.2, 1.3, 1.4, 1.5, 1.6, 1.7, 1.8 ,etc single-layer nozzles are specially used for high-power cutting.

How to selecting the right nozzle for your application?

1. Look at the material: a good nozzle must have high electrical conductivity and good thermal conductivity to form a stable capacitance signal with the processed material. T2 copper is a good choice

2. Look at the precise (accuracy): Coaxiality is the core index for testing a nozzle. Conventional (within 3000 watts) coaxiality is required to be 0.03mm; for high power (10,000 watts), coaxiality is required to be 0.01mm. The different axis between the nozzle center and the laser center will have the following effects:

A. One side of the cutting section is normal, while the other side is slag spatter due to the gas ejection center is not uniform with the laser center.

B. Bad quality of sharp corners: It is easy to overburn when cutting sharp corners;

C. Unstable during piercing: It is easy to cause local location over-melting and blasting;

3. Surface finish: The high surface finish can effectively reduce the adhesion of the processed melt and the absorption of laser energy (overheating) by the nozzle body during positive or negative focus processing.

4. Runner design: The scientific runner design is conducive to the cutting of different materials, the discharge of molten slag, and the anti-slag damage nozzle and protective lens during processing.