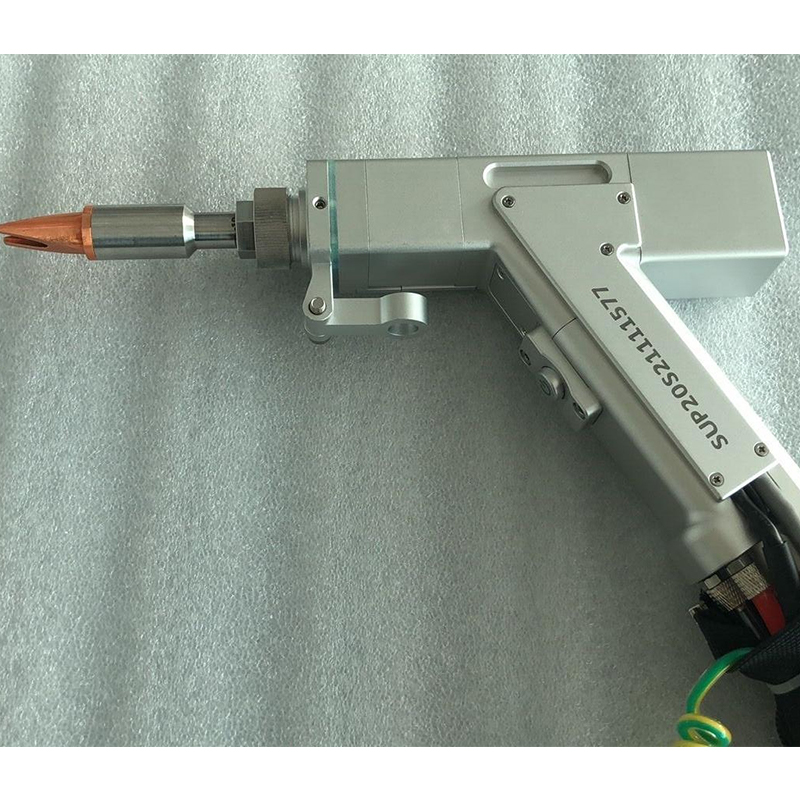

hand held wobble laser welding head SUP20S

1.Overview

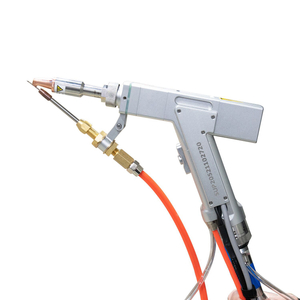

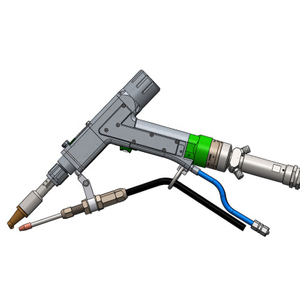

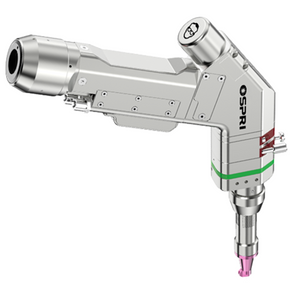

Double swing welding head SUP20SW150 is a brand-new dual-motor scanning swing welding head used in platform welding - referred to as double swing welding head. The product covers double pendulum welding head and self-developed control system, and sets up multiple safety alarms and active safety power-off and light-off settings. It is developed on the basis of the hand-held welding head that our company has produced in large quantities, and has the characteristics of high reliability and strong stability. This product can be adapted to various brands of fiber lasers, and the optical and water-cooled design is optimized so that the laser head can work stably for a long time at 2000W.

Product features:

●Basic features: The self-developed double pendulum control system provides a variety of scanning pattern options for different process requirements, sets multiple security alarms, and is simple and flexible to operate. ●More stable: All parameters are visible, real-time monitoring of the state of the whole machine, to avoid problems in advance, to facilitate troubleshooting and troubleshooting, and to ensure the stable operation of the double pendulum welding head.

●Technology: Provides a variety of craft graphics options, graphics parameters can be set, you can try various craft effects.

●The parameters are controllable and the repeatability is high. Stable nozzle air pressure and lens state, as long as the laser power is stable, the process parameters must be repeatable, which greatly improves the efficiency.

Operating environment requirements and main parameters of double pendulum welding head

Supply voltage (V) 220V±10%AC50/60Hz

placement environment

Flat, vibration and shock free

Working environment temperature (℃) 10~40

Working environment humidity (%)<70

Cooling method water cooling

Applicable wavelength 1064nm (±10nm)

Applicable power≤2000W

Collimation D16*4.5/F60

Focus D20*4.5/F150

Reflection 15.2*15.2T1.615.2*20T1.6

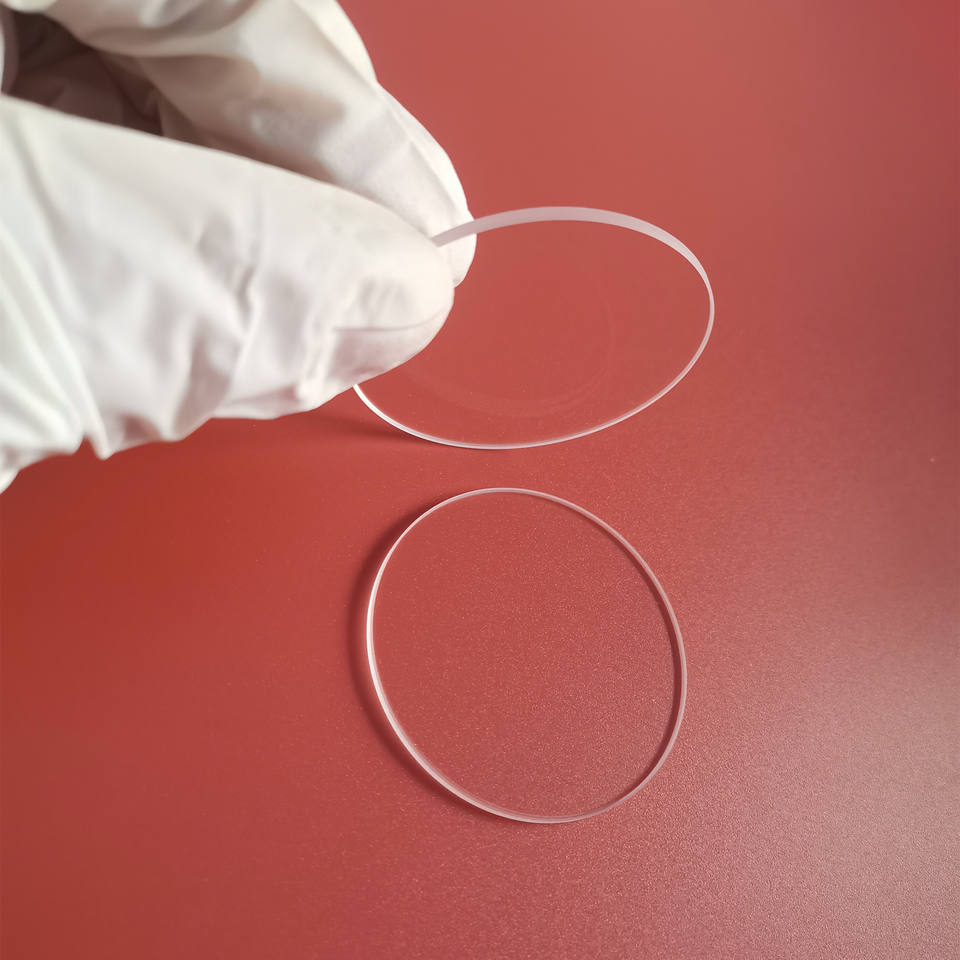

Protective mirror specification 18*2

Maximum support air pressure 15Bar

Focus vertical adjustment range ±10mm

Effective clear aperture 12mm

Weight 1.4kg

(1) Ensure reliable grounding before power supply.

(2) The laser output head is connected with the welding head. Please check the laser output head carefully when using it to prevent dust or other pollution. Please use special lens paper when cleaning the laser output head.

(3) If the equipment is not used according to the method specified in this manual, it may be in abnormal working state and cause damage.

(4) When replacing the protective glasses, please make sure to protect them well.

(5) Please note: When using for the first time, when the red light cannot come out from the copper mouth, be sure not to emit light.

Common exception handling

①If the above alarm occurs without using the alarm signal, please change the alarm level on the screen setting page.

②If the above alarm occurs when the alarm signal is used, check whether the alarm of the corresponding equipment or the level of the alarm signal is set incorrectly.

①The screen does not light up, make sure the controller is powered on, check whether the four-core wire between the controller and the screen is connected correctly, and whether the 24V voltage of the 1st pin and the 4th pin is normal.

②If the click fails during normal use, check whether the temperature of the whole machine is too high.

③Click can not input, check whether the four-core wire between the controller and the screen is connected correctly, and whether the second and third pins are normal, see 2.1.

④If there is no response when clicking on the newly installed device, it may be that the system version does not match. You can use the SD card to refresh the program. Please ask our company for the specific version.

①Check whether there is an alarm prompt on the home page and whether the laser enable is ON;

② When welding, check whether the trigger signal and safety lock signal of the monitoring page are displayed in green;

③ When welding, check whether the PWM, laser enable, and analog output on the monitoring page are normal. If the above states are normal, please check whether the laser has abnormal alarms.

For example: the air is sent out and the wire is fed but no light is emitted, which means the laser is faulty or the laser wiring is wrong. If neither air nor wire is fed, the input signal may be missing, see: 2.1.3 Controller Signal Interface 1 for details. Check whether the monitoring interface safety lock and other alarms are normal.