Fscut 2000S Medium Power Laser Cutting Control System

FSCUT2000C laser cutting control system User Manual.pdf

FSCUT2000C laser cutting control system User Manual.pdf

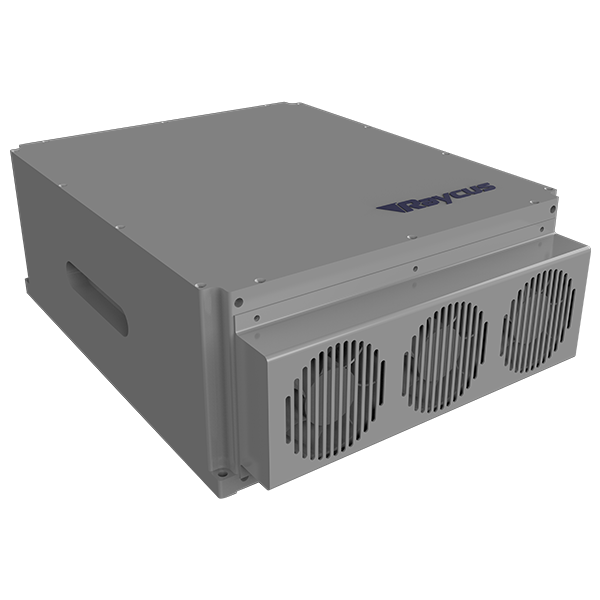

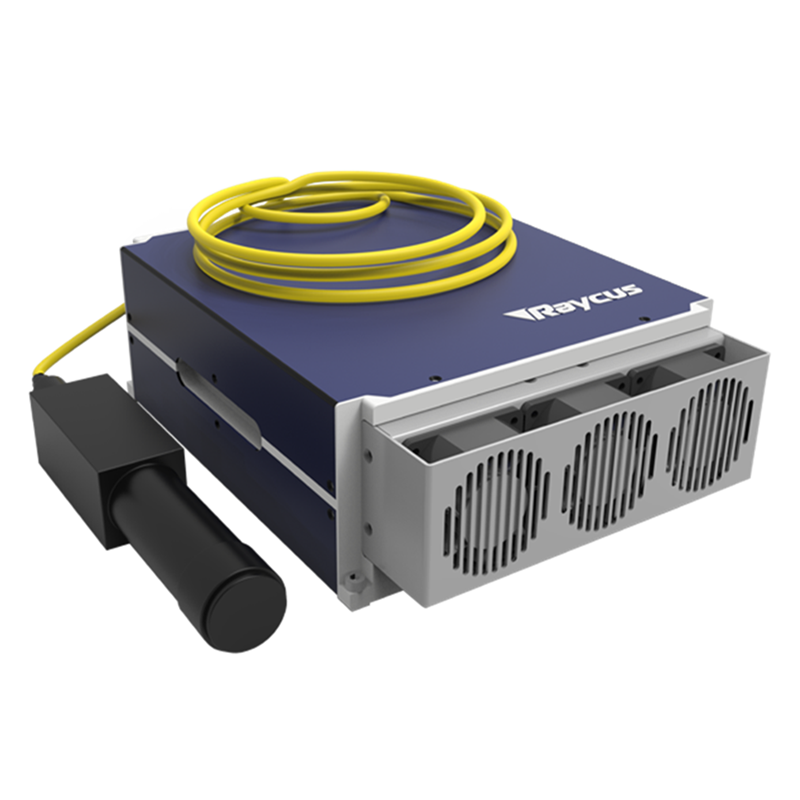

FSCUT2000S is the upgrade version from FSCUT2000C, it is a high-performance open loop laser control system developed independently by Shanghai Friendess Electronic Technology Co., Ltd. It is widely used in the field of metal and non-metal laser cutting. Because of its outstanding performance in the field of medium power fiber laser cutting, it is favored by a large number of high quality customers.

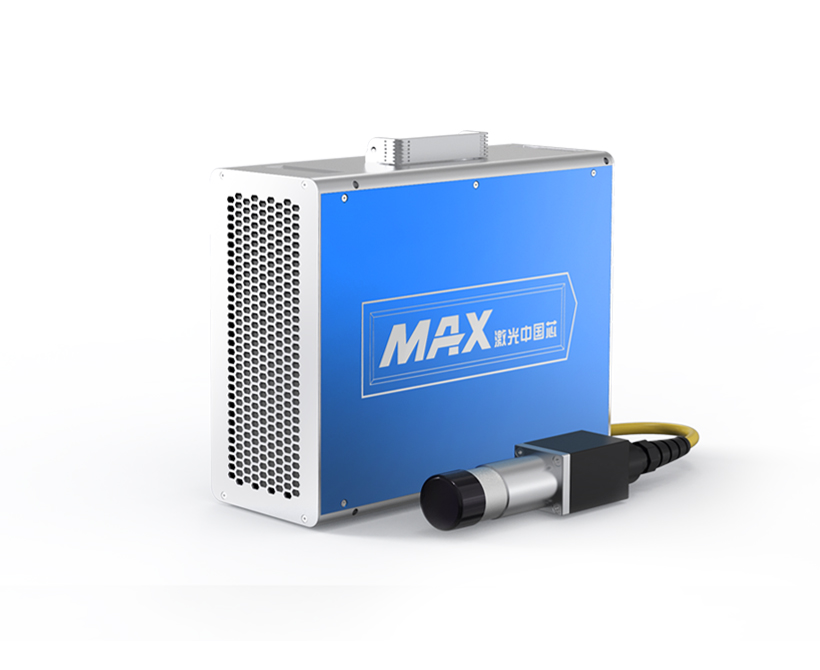

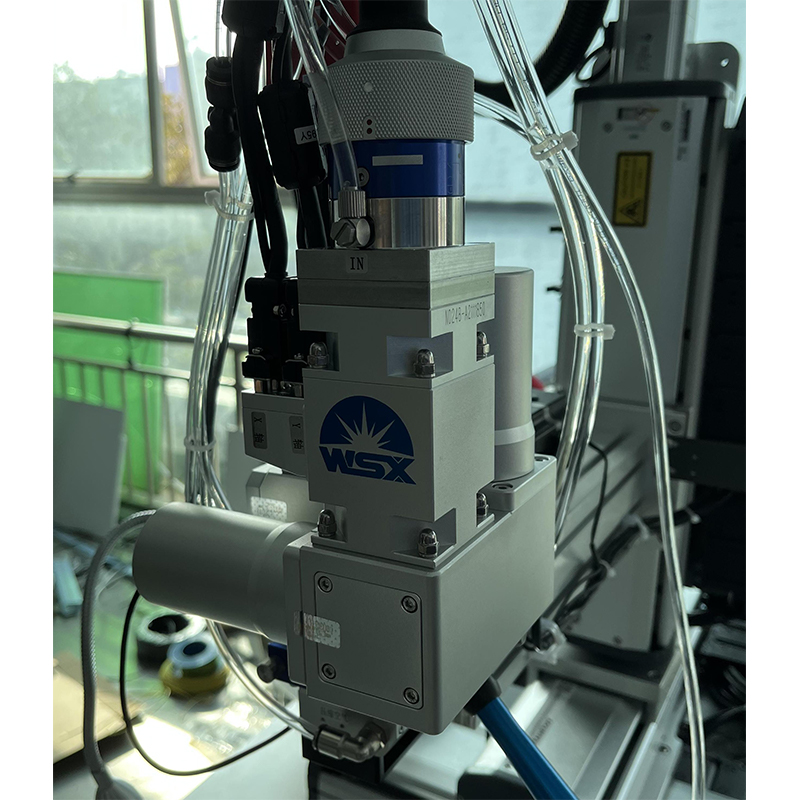

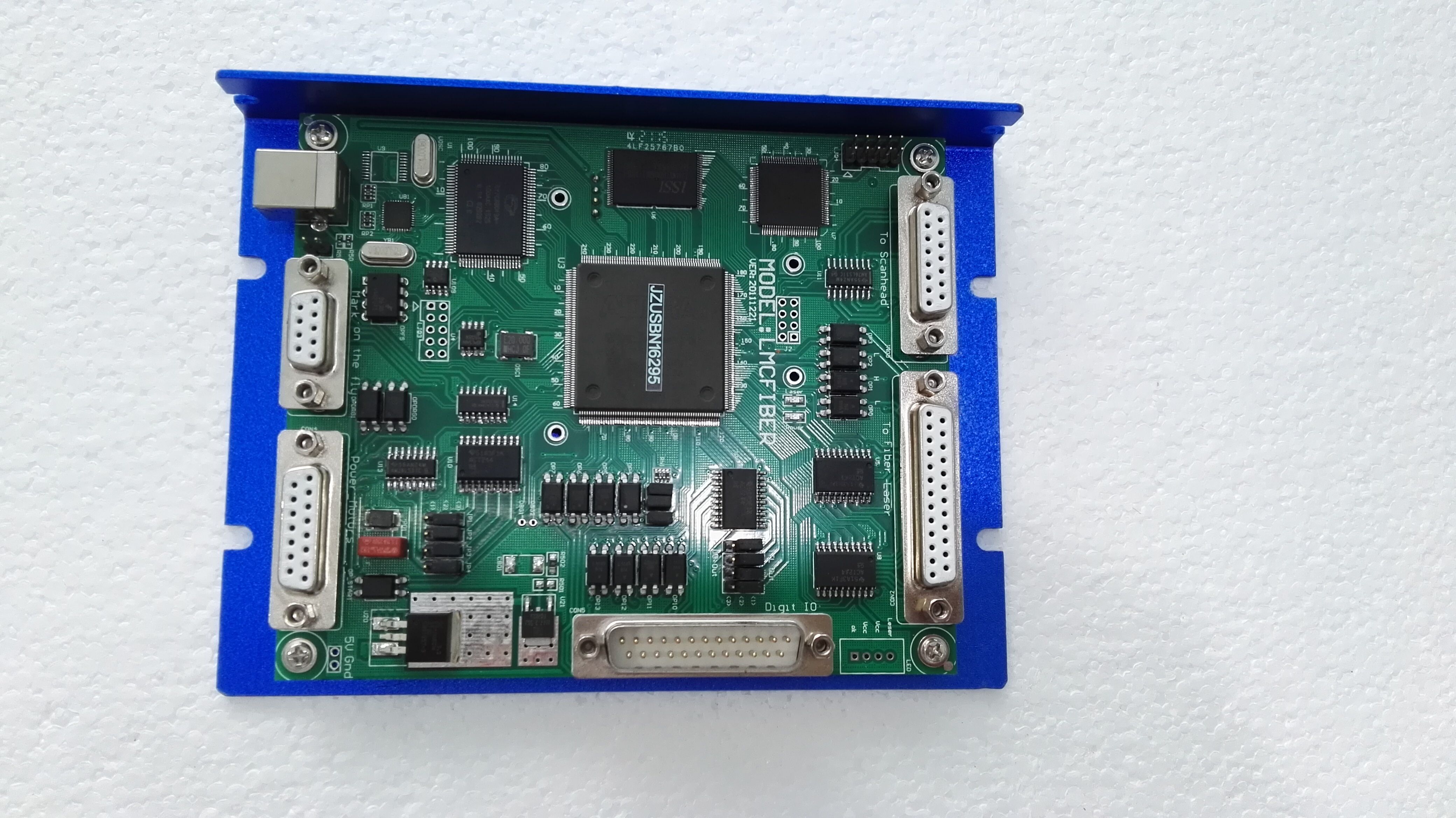

FSCUT2000S laser cutting control system is composed of standard accessories as shown below:

| Description | Model | Amount |

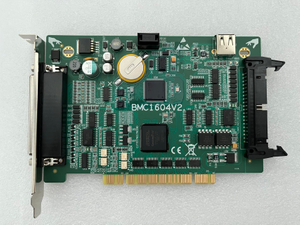

Motion control card

| BMC2104

| 1 |

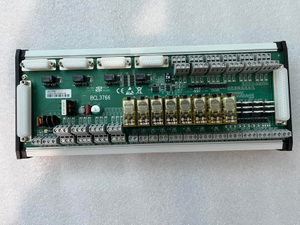

| Terminal board | BCL3766

| 1 |

| 15-Pin cable (2.5m) | C15-2.5 | 2 |

37-Pin cable (2m)

| C37-2

| 1 |

62-Pin cable (2m)

| C62-2

| 1 |

Servo cable (2.5m)

| C15-2.5 | 4

|

Laser software

| CypCut

| 1 |

Wireless remote

| WKB V6 | 1 |

CNC panel

| BCS100 | 1 |

| Amplifier | BCL-AMP | 1 |

| SPC | SPC-140 | 2 |

Technical parameters:

| Model | FSCUT2000 |

| Motion Control card | BMC1604v2 |

| I/O terminal board | BCL3766 |

| Motor control signal | X/Y1/Y2/W axes pulse output, maximum frequency 3MHz |

| X/Y1/Y2 axes port receive encoder feedback, highest sampling frequency 10MHz |

| W axis port can be assigned as rotary axis or autofocus unit |

| Dedicated inputs | 8 limit inputs: +/-limit for X/Y1/Y2/W axes |

| 4 origin inputs: X / Y1 / Y2 / W axes origin signal inputs: |

| Common inputs | 15 inputs: low-level active by default option, supports NO and NC mode. IN3~IN15 can switch between active low and active high |

| Software | CypCut Laser Cutting Control Softwar |

| Interface type | PCIE bus, X16, 250MB/S |

| Motion control performance | Open-loop control system with Friendess 3rd generation motion control algorithms. |

| Trajectory accuracy 0.03mm, positioning accuracy 0.001 mm, repetitive positioning accuracy 0.003 mm. |

| Maximum cutting speed 80m/min, maximum position speed 150m/min. |

| Maximum acceleration 1.5G. |

| Provide dual-Y drive position error detect function. |

| Laser control signal | Output 1 is PWM signal, with dip switch choosing 24V or 5V |

| Output 2 is 0~10V analog signal. |

| I/O Function | 12 general inputs. |

| 20 general outputs, thereto, 8 interfaces are relay outputs,12 interfaces are mosfet emitter outputs. |

| Work environment | Temperature: 0~55℃ |

| humidity: 5%~90%, no condensation Power |

| Power requirement | 24V DC/2A |

Advantages:

| Cutting technique | Support up to 5-stage piercing technique, segment and stepping piercing patterns. |

| Support the communication with mainstream laser brands on the market. |

| Support basic technique of Fly cut, frog-leap lifting, kerf width compensation, lead line, micro-joint, pre-piercing, film cutting etc. |

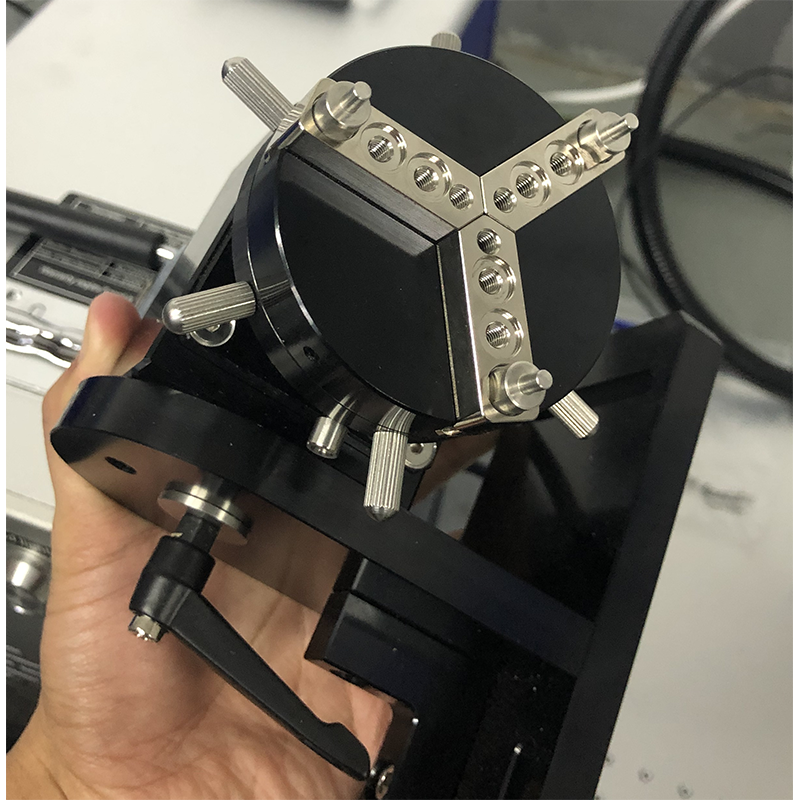

| Support advanced functions of find workpiece edge, auto focus control, dual shuttle, break point locate, QR code generation, remnant split, round tube cutting etc. |

| Provide fine cutting technique, smooth start and end in the toolpath cutting. |

| Support intelligent barrier avoidance, laser head frog-leap lifting in production. |

| Support scan QR import drawing, task scheduling, and multi-area production etc. |

Application:

Applicable to 1500W ~ 6000W medium power fiber laser cutting machine, widely used in fabricating industries of metal workpiece, kitchen utensils, lamps, cabinets and more.