Tube Laser Cutting Control System Fscut 3000S for Pipe (rectangle, Circle,ellipse Steel Channels T/C/U/H/L Shape Cutting

FSCUT3000S-tube laser cutting controller system User-Manual-V1.4.pdf

FSCUT3000S-tube laser cutting controller system User-Manual-V1.4.pdf

FSCUT3000S system is designed for tube cutting control, support standard tube(rectangle, circle, oval, ellipse and obround etc.) , free form , and steel channels(T/U/H/L shape) production of high precision and efficiency.

FSCUT3000S Tube laser cutting control system is composed of standard accessories as shown below:

| Description | Model | Amount |

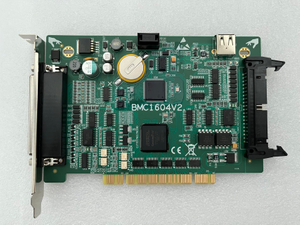

Motion control card

| BMC1805

| 1 |

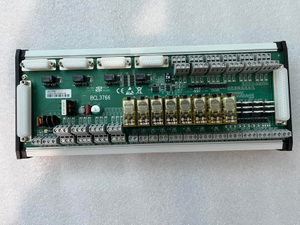

| Terminal board | BCL3766

| 1 |

| Flat cable | C37-40 | 1 |

37-Pin cable (2m)

| C37-2

| 1 |

62-Pin cable (2m)

| C62-2

| 1 |

Servo cable (21.5m)

| C15-1.5 | 4

|

| Cutting control software | TubePro | 1 |

| Nesting software(optional) | TubesT/TubesT-Lite | 1 |

Wireless remote

| WKB | 1 |

| Control panel(optional) | BCP5045 | 1 |

Technical parameters:

| Model | FSCUT 3000S |

| Motion Control card | BMC1805 |

| I/O terminal board | BCL3766 |

| Motor control signal | X/Y1/Y2/W axes pulse output, maximum frequency 3MHz |

| X/Y1/Y2 axes port receive encoder feedback, highest sampling frequency 10MHz |

| W axis port can be assigned as rotary axis or autofocus unit |

| Dedicated inputs | 8 limit inputs:Positive and negative limit for X/Y1/Y2/W axis |

| 4 origin inputs:X / Y1 / Y2 / W axis origin |

| Dedicated output | 2 DA: 0~10V,50mA |

| 1 PWM with 5V/24V for option, precision of 5KHz (0.1%) |

| Common inputs | 15 inputs: 12 are low-level active, 3 inputs can jump-wire switch to high-level active. |

| Common output | 8 relay output, load capacity 250V AC/5A, 30V DC/5A |

| 12 thyristor output, DC 24V/500mA |

| Software | TubePro tube cutting software/ CypCut sheet cutting software |

| Interface type | 32-bit PCI bus, 132MB/S |

| Motion control performance | Open-loop control system with Friendess 3rd generation motion control algorithms. |

| Trajectory accuracy 0.03mm, positioning accuracy 0.001 mm, repetitive positioning accuracy 0.003 mm. |

| Maximum cutting speed 80m/min, maximum position speed 150m/min. |

| Maximum acceleration 1.5G. |

| Provide dual-Y drive position error detect function. |

| Laser control signal | Output 1 is PWM signal, with dip switch choosing 24V or 5V |

| Output 2 is 0~10V analog signal. |

| I/O Function | 12 general inputs. |

| 20 general outputs, thereto, 8 interfaces are relay outputs,12 interfaces are mosfet emitter outputs. |

| Work environment | Temperature: 0~55℃ |

| humidity: 5%~90%, no condensation |

| Power supply requirement | 24V DC/2A |

Advantages:

| Cutting technique | Support offset tube center error in production to improve through holes cutting precision. |

| Support steel channels ((T/C/U/H/L shape) cutting. |

| Suppport seperate technique for corner cutting. |

| Support auto loading/unloading process, cycle production and automatic tube feeding. |

| Support all functions of FSCUT2000 system. |

| Control performance | Open-loop control system, Friendess 5th generation motion control algorithms. |

| Trajectory accuracy 0.02mm, positioning accuracy 0.001mm, repeatability 0.003mm. |

| Access encoder feedback in real time, to compare command and machine toolpath. |

Application:

Applied in tube cutting or tube-sheet combo machine. Widely used in furniture, display shelf, architecture, and sport equipment industries. support standard tube(rectangle, circle, oval, ellipse and obround etc.) , free form , and steel channels(T/U/H/L shape) production of high precision and efficiency.