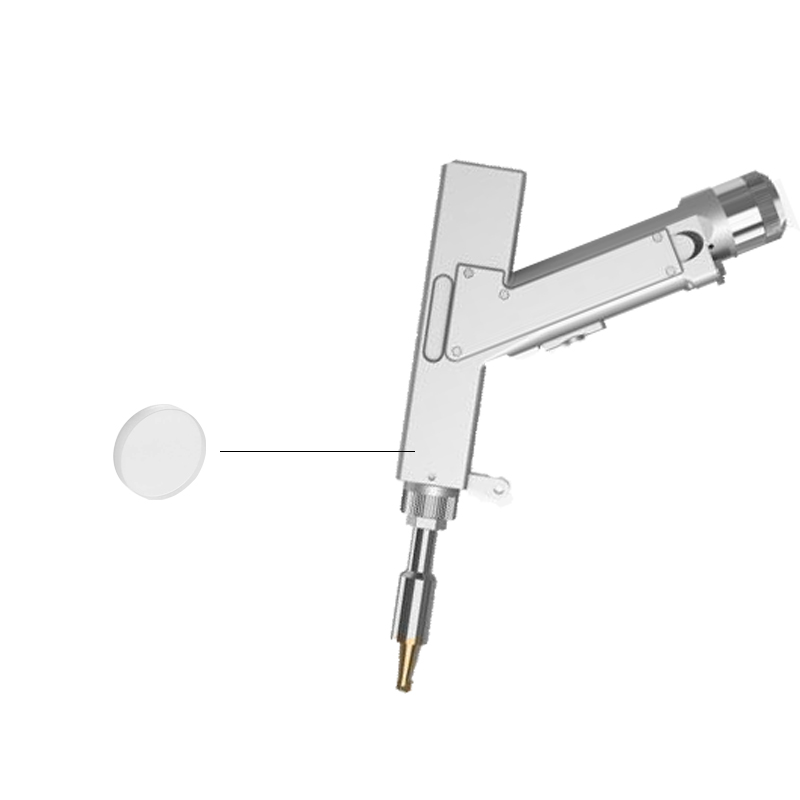

The Raytools cutting head is a crucial component in modern laser cutting systems, known for its precision and efficiency. This cutting head is equipped with a water-cooled QBH fiber optic connector, which is designed for high-performance laser applications, ensuring optimal heat management and improved cutting quality.

specifications for the QBH connectors and QD components:

| Item Description | Part Number |

| QBH Non-Water-Cooled | 211FIA1001 |

| QBH Water-Cooled | 211FIA3003 |

| QBH Old Model Water-Cooled | 211FIA1003 |

| QD Component | 211FIA3002 |

| QD Component | 211FIA0003 |

Water-Cooled QBH Connector:

The water-cooled QBH connector effectively dissipates heat generated during the cutting process, enhancing the performance and longevity of the laser system.

This cooling mechanism is essential for maintaining stable laser operation, especially during high-power cutting tasks.

Quick Disconnect (QD) Functionality:

The QD connector allows for rapid and easy connection and disconnection of the fiber optic cable, facilitating quick maintenance and minimizing downtime.

This feature enhances operational efficiency, making it convenient for operators to switch cutting heads or perform system checks.

Precision Cutting:

The Raytools cutting head is engineered for high precision and can handle a variety of materials, including metals, plastics, and composites.

It supports different cutting thicknesses, providing versatility for various applications in manufacturing and fabrication.

Advanced Beam Delivery:

The cutting head incorporates advanced optics to ensure optimal beam delivery, resulting in clean cuts and minimal kerf width.

This precision leads to reduced material waste and improved overall efficiency.

Compatibility:

The Raytools cutting head is compatible with a wide range of fiber laser systems, making it a versatile choice for many industrial applications.

It can be integrated into existing laser cutting machines with relative ease.

Applications

The Raytools cutting head with water-cooled QBH fiber optic connector and QD functionality is widely used in industries such as:

Metal Fabrication: For cutting various metals, including steel, aluminum, and copper.

Automotive Manufacturing: Used for producing precision components in vehicle assembly.

Aerospace: For cutting lightweight materials and structures.

Electronics: In the production of electronic components and housings.

Signage and Displays: For cutting intricate designs in various materials.

Conclusion

The Raytools cutting head, featuring a water-cooled QBH fiber optic connector and QD functionality, represents a significant advancement in laser cutting technology. Its ability to manage heat effectively, combined with the convenience of quick disconnect features, enhances productivity and precision in various industrial applications. This cutting head is a valuable investment for businesses looking to improve their laser cutting capabilities.